Microcombustion heater having heating surface which emits radiant heat

A micro-combustion and heater technology, which is applied to burners, gas fuel burners, combustion methods, etc., can solve the problems of expensive electric heater consumption and uneconomical heaters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, embodiments according to the present invention will be described with reference to the drawings.

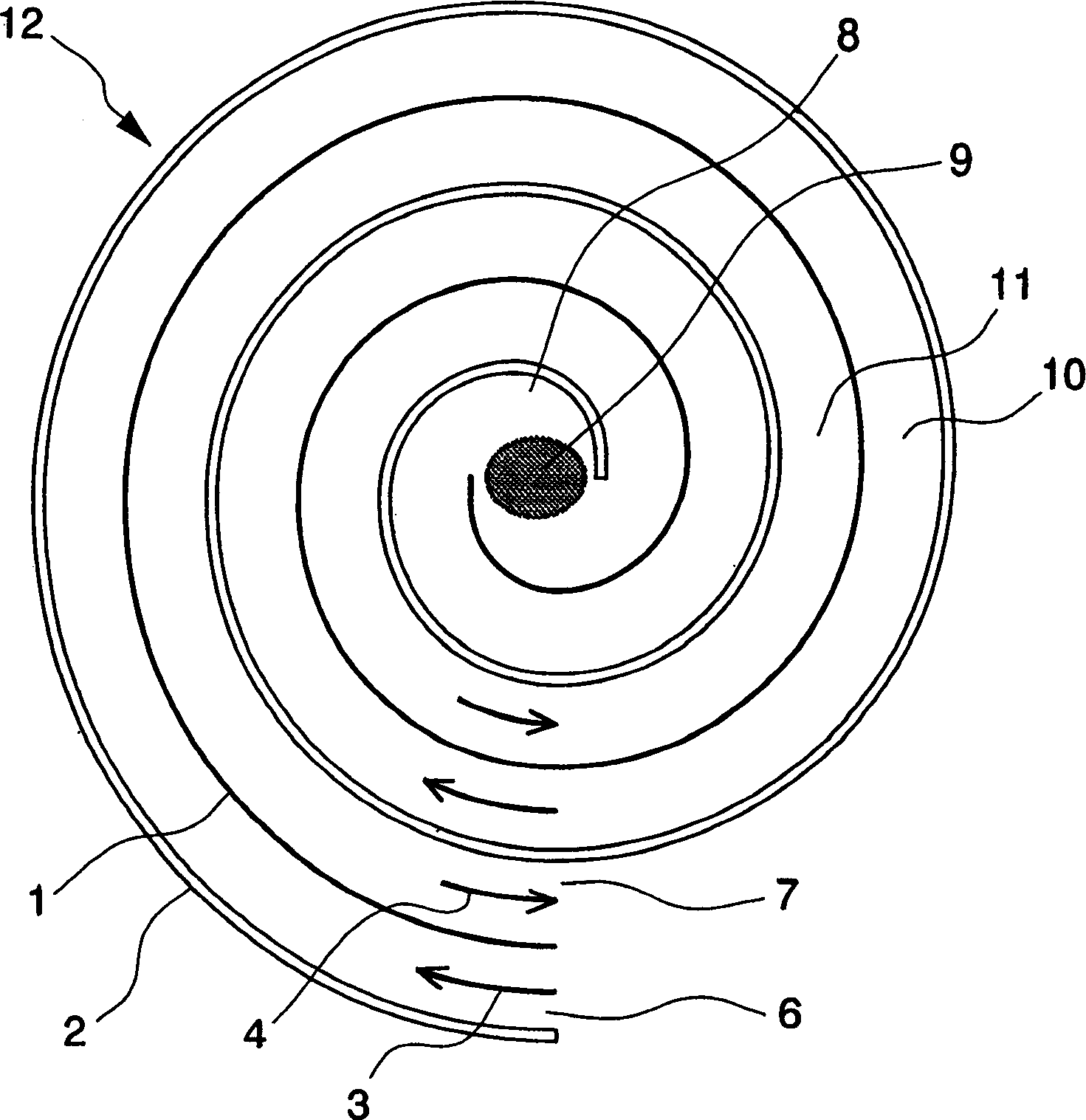

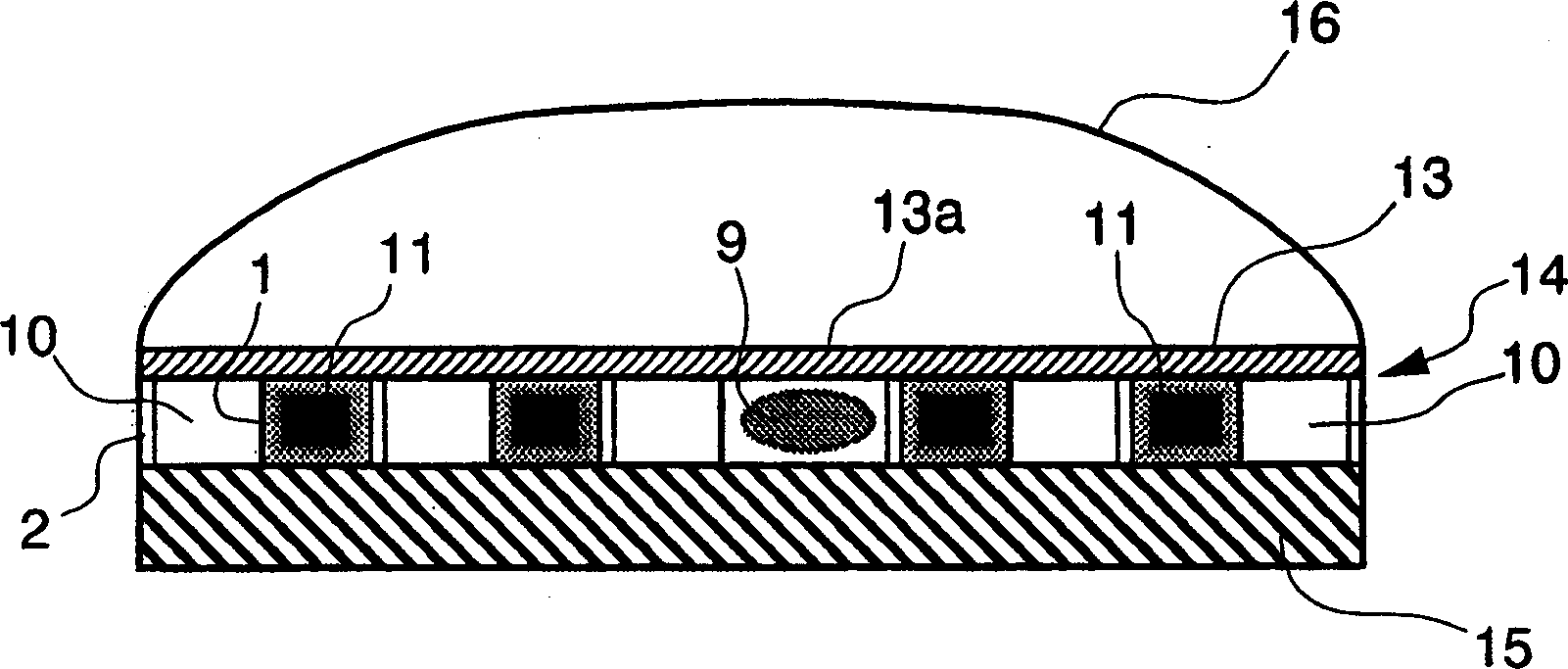

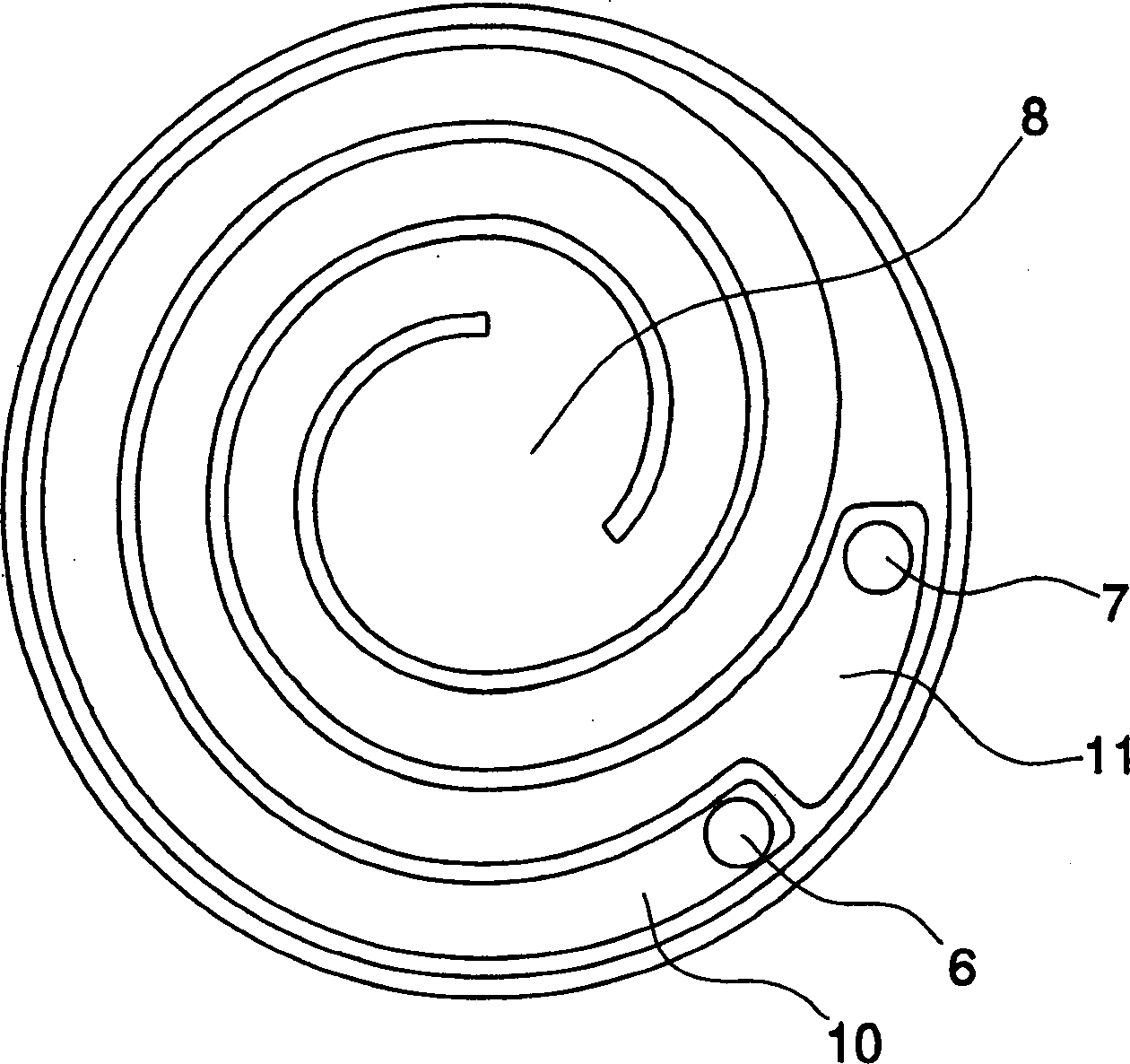

[0035] Figure 1A and 1B It is a configuration diagram showing a micro-combustion heater as an embodiment of the present invention. Figure 1A is a cross-sectional view in a plane parallel to the heating surface (explained below), Figure 1B is a cross-sectional view along the centerline. In these figures, corresponding to the above Figure 5A and 5B The same reference numerals are used for the same parts, and the same explanations will be simplified or omitted.

[0036] exist Figure 1A and 1B In , reference numeral 1 denotes a heating wall, and reference numeral 2 denotes an insulating wall.

[0037] As shown in the figure, a channel 10 for the premixed gas of air and gas drawn into the combustion chamber 8 and a channel 11 for the gas sucked out of the combustion chamber 8 to heat the wall 1 is arranged between the channels 10 and 11 way to form. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com