Rope transmission mechanism

A technology of rope transmission and rope pulley, which is applied in the direction of transmission devices, mechanical equipment, belts/chains/gears, etc., can solve the problems of unsuitable transmission of super high power, high cost of gear transmission, inaccurate transmission ratio, etc., so as to save the need for deceleration The effect of low material requirements for the machine and wheel body and simple structure of the sheave

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

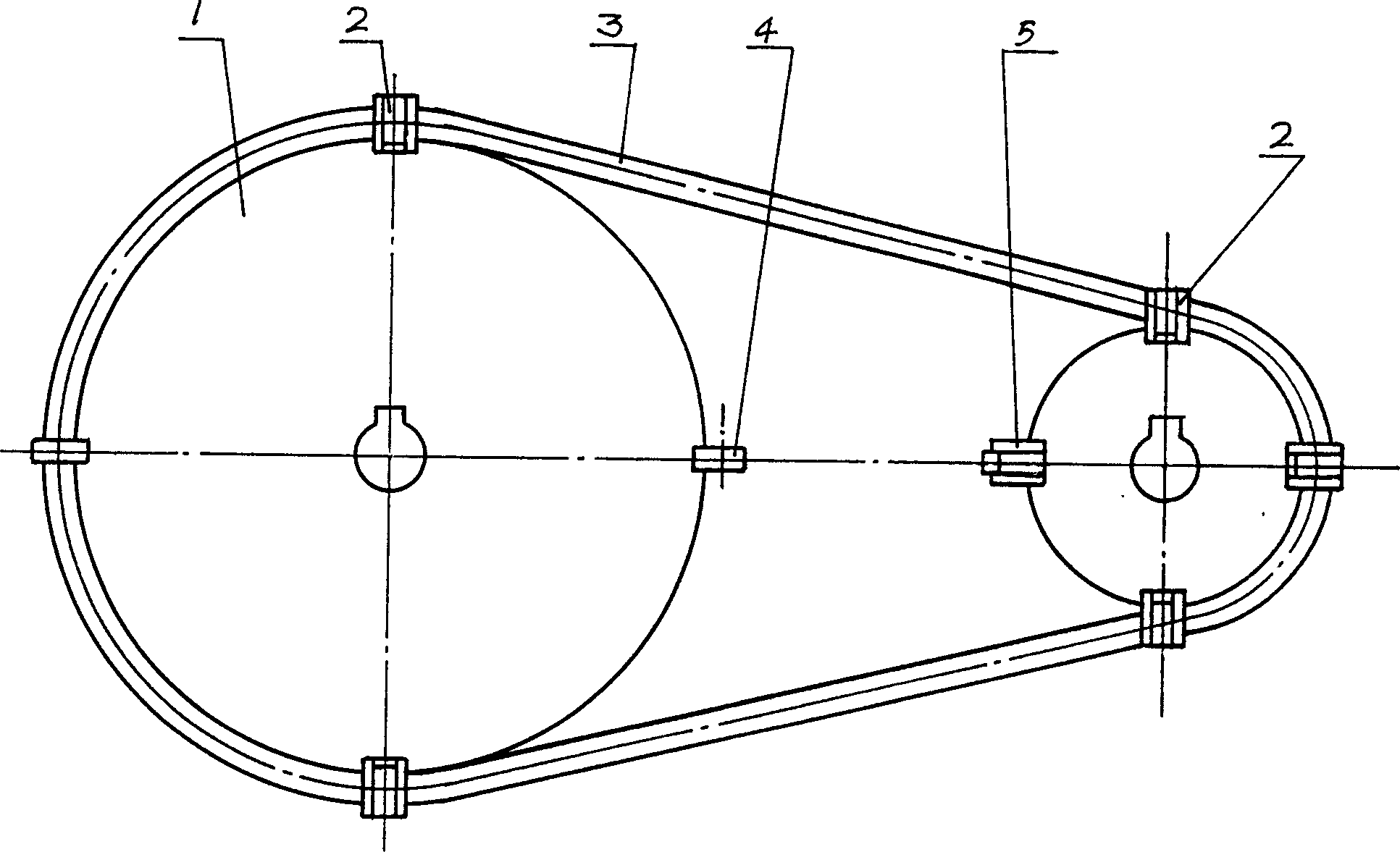

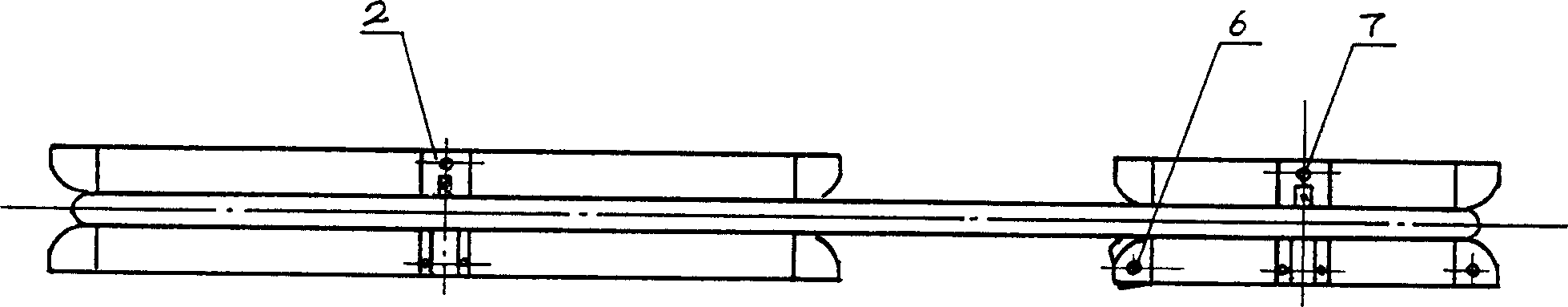

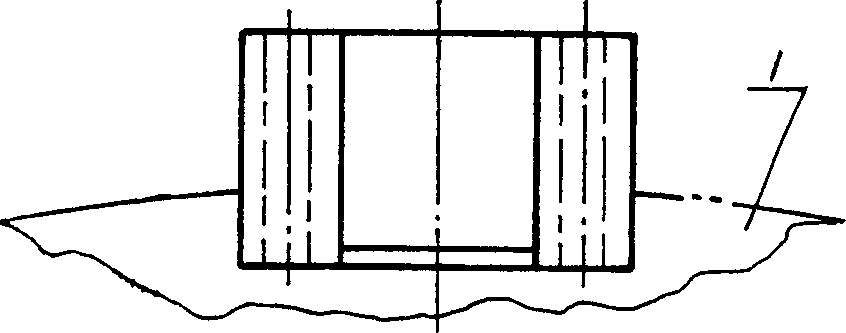

[0035] refer to Figure 1 to Figure 19 , the outer edge of the rope wheel 1 does not have the buckle 2 and the flat plate tripping 4 that are fixed with the wheel 1, and the rope 3 that forms the loop is tightly placed on the two wheels 1. Buckle 5 is the buckle when the rope is not buckled (compared to Image 6 or Figure 15 ), buckle 2 is fixedly installed by fastening bolt 7 and wheel 1. The buckle bolt 9 is looped on the buckle shaft 6, and is inserted into the buckle frame 8 alive. Rope 3 is fastened by fastening point 11 ( Figure 4 There are two fastening points 11 on it, so it is called multi-point buckle; Figure 12 There is a fastening point 11 on it, so it is called a single-point buckle), a rope-passing notch 12 is formed between the buckle bolt 9 and the buckle frame 8, and there are corresponding rope-passing notches on the flat trip 4 and the multi-pile trip 14 12. Flat studs are mainly suitable for passing knotted ropes, and multi-pile trips 14 are mainly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com