Phase change material

A technology of phase change materials, sodium acetate trihydrate, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of poor performance stability, low latent heat of phase change, strong corrosion, etc., and achieve low cost and phase change The effect of reversible process and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] (1) prepare materials, select industrial grade sodium acetate trihydrate [CH 3 COONa·3H 2 O] and urea [CO(NH 2 ) 2 ] were ground separately; using anhydrous sodium acetate [CH 3 COONa] mixed with water in a mass ratio of 41:27 to form sodium acetate trihydrate;

[0015] (2) Press CH 3 COONa·3H 2 O and CO(NH 2 ) 2 The mass ratios are 65% and 35% respectively, mixed and stirred evenly, and put into a glass or ceramic container;

[0016] (3) Heat the container in a water bath at about 70°C, and keep stirring while heating, the mixture will gradually melt and gradually turn into a transparent liquid;

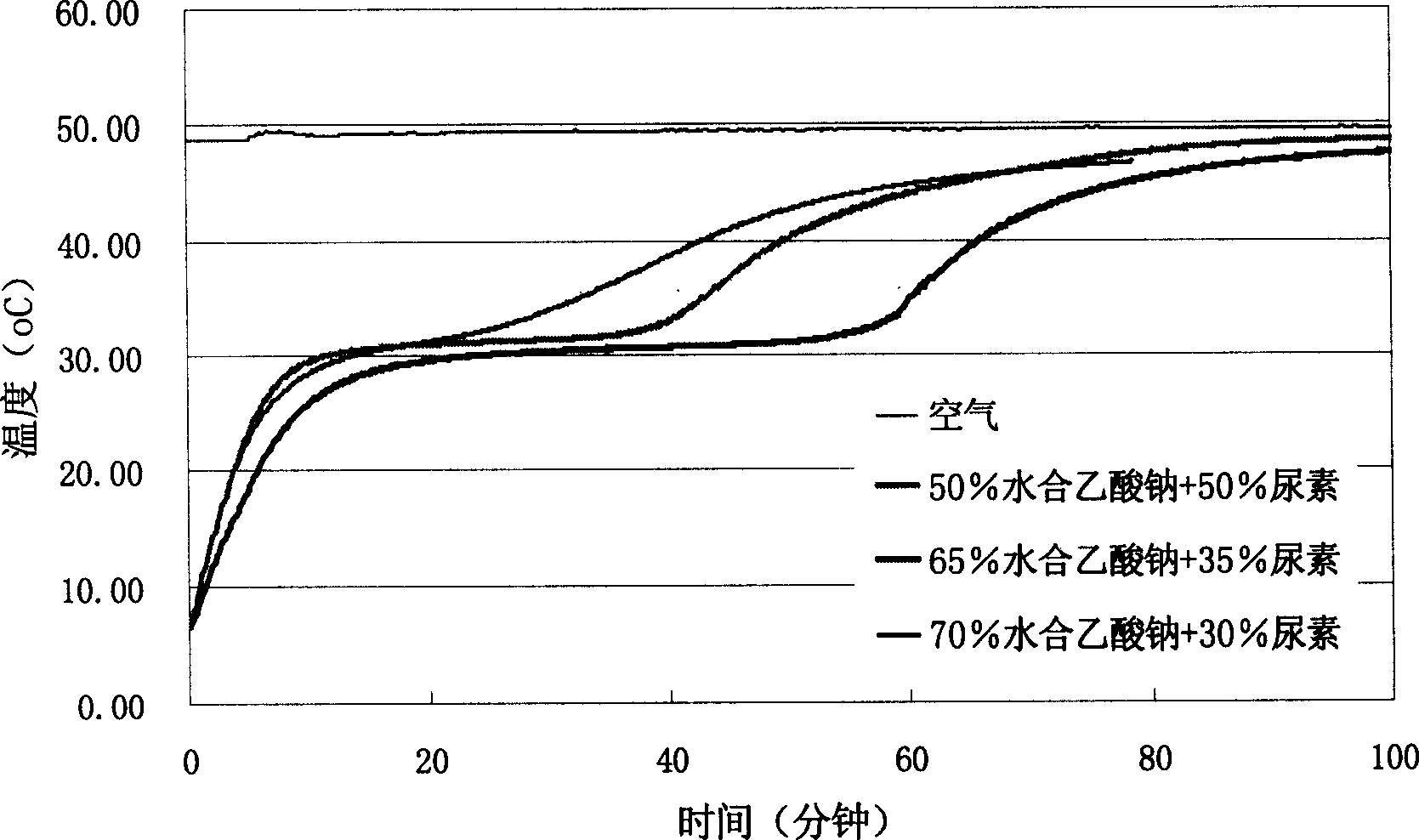

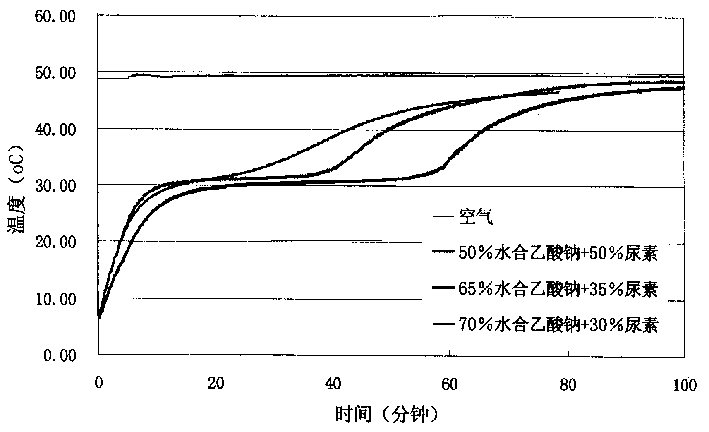

[0017] The phase change temperature of the prepared phase change material is 29-32°C, and the latent heat of phase change is 230kJ / kg, see attached figure 1 .

Embodiment 2

[0019] (1) prepare materials, select industrial grade sodium acetate trihydrate [CH 3 COONa·3H 2 O] and urea [CO(NH 2 ) 2 ] were ground separately; using anhydrous sodium acetate [CH 3 COONa] mixed with water in a mass ratio of 41:27 to form sodium acetate trihydrate;

[0020] (2) Press CH 3 COONa·3H 2 O and CO(NH 2 ) 2 The mass ratio is 50% and 50% respectively, mixed and stirred evenly, and put into a glass or ceramic container;

[0021] (3) Heat the container in a water bath at about 75°C, and keep stirring while heating, the mixture will gradually melt and turn into a transparent liquid.

[0022] The phase change temperature of the prepared phase change material is 29-33°C, and the latent heat of phase change is 170kJ / kg, see attached figure 1 .

Embodiment 3

[0024] (1) prepare materials, select industrial grade sodium acetate trihydrate [CH 3 COONa·3H 2 O] and urea [CO(NH 2 ) 2 ] were ground separately; using anhydrous sodium acetate [CH 3 COONa] mixed with water in a mass ratio of 41:27 to form sodium acetate trihydrate;

[0025] (2) Press CH 3 COONa·3H 2 O and CO(NH 2 ) 2 The mass ratios are 70% and 30% respectively, mixed and stirred evenly, and put into glass or ceramic containers;

[0026] (3) Heat the container in a water bath at about 65°C, and keep stirring while heating, the mixture will gradually melt and turn into a transparent liquid;

[0027] The phase change temperature of the prepared phase change material is 26-33°C, and the latent heat of phase change is 120kJ / kg, see attached figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com