Method and system for radiation detecting cut tobacco filling value

A technology of radiation measurement and filling value, applied in measurement devices, specific gravity measurement, material analysis using radiation, etc., can solve problems such as undisclosed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

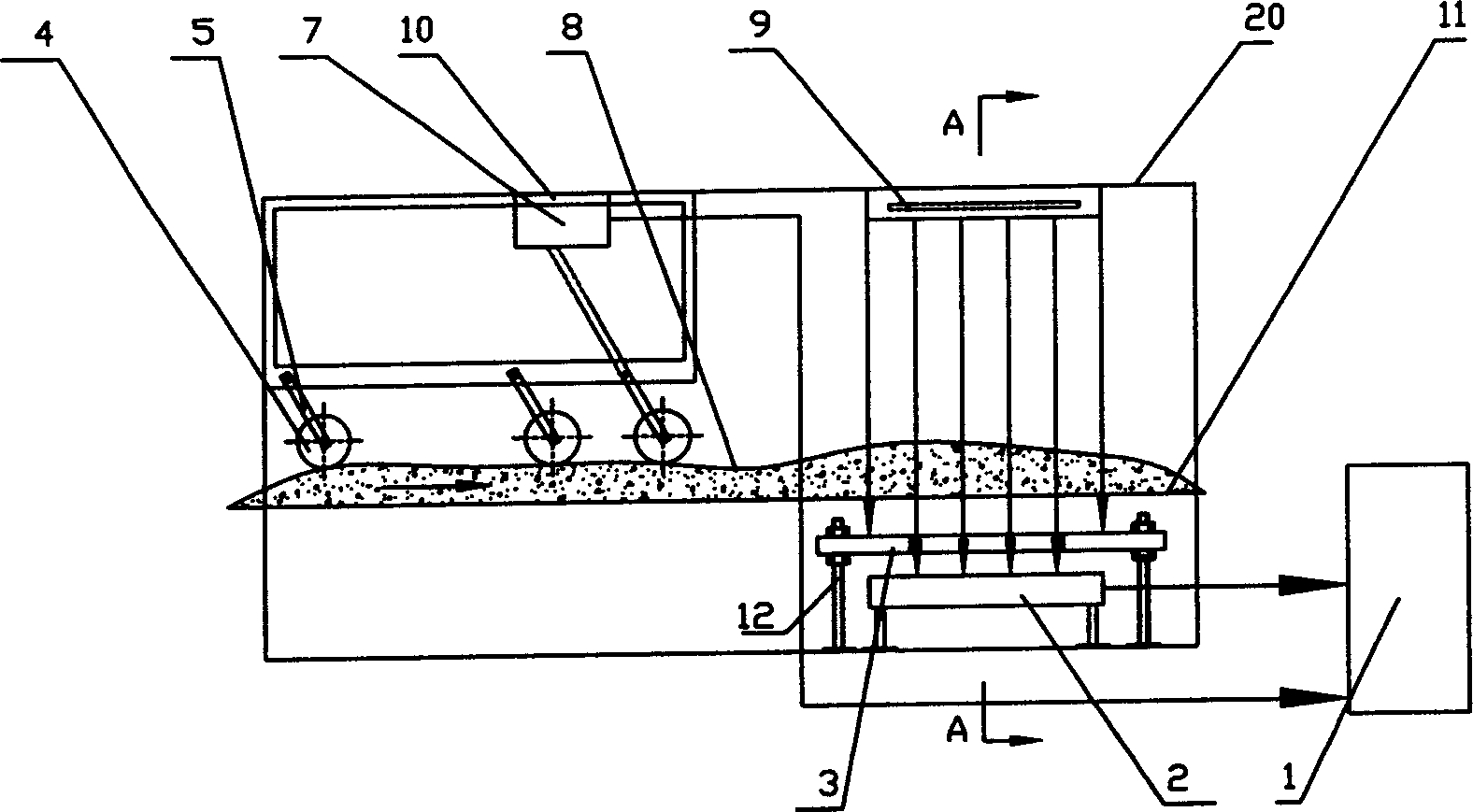

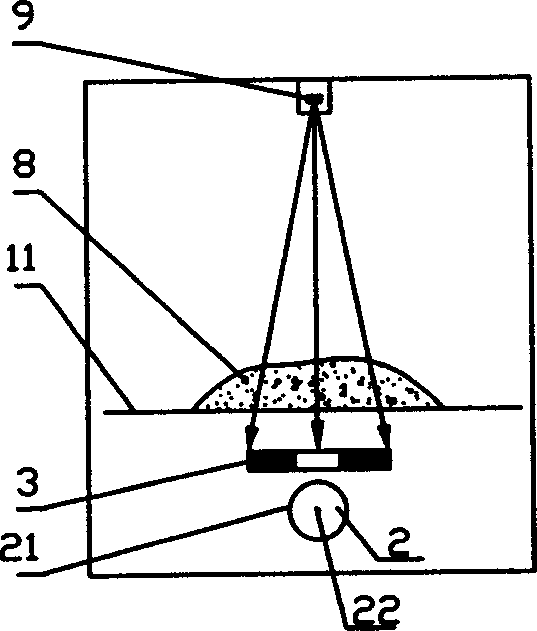

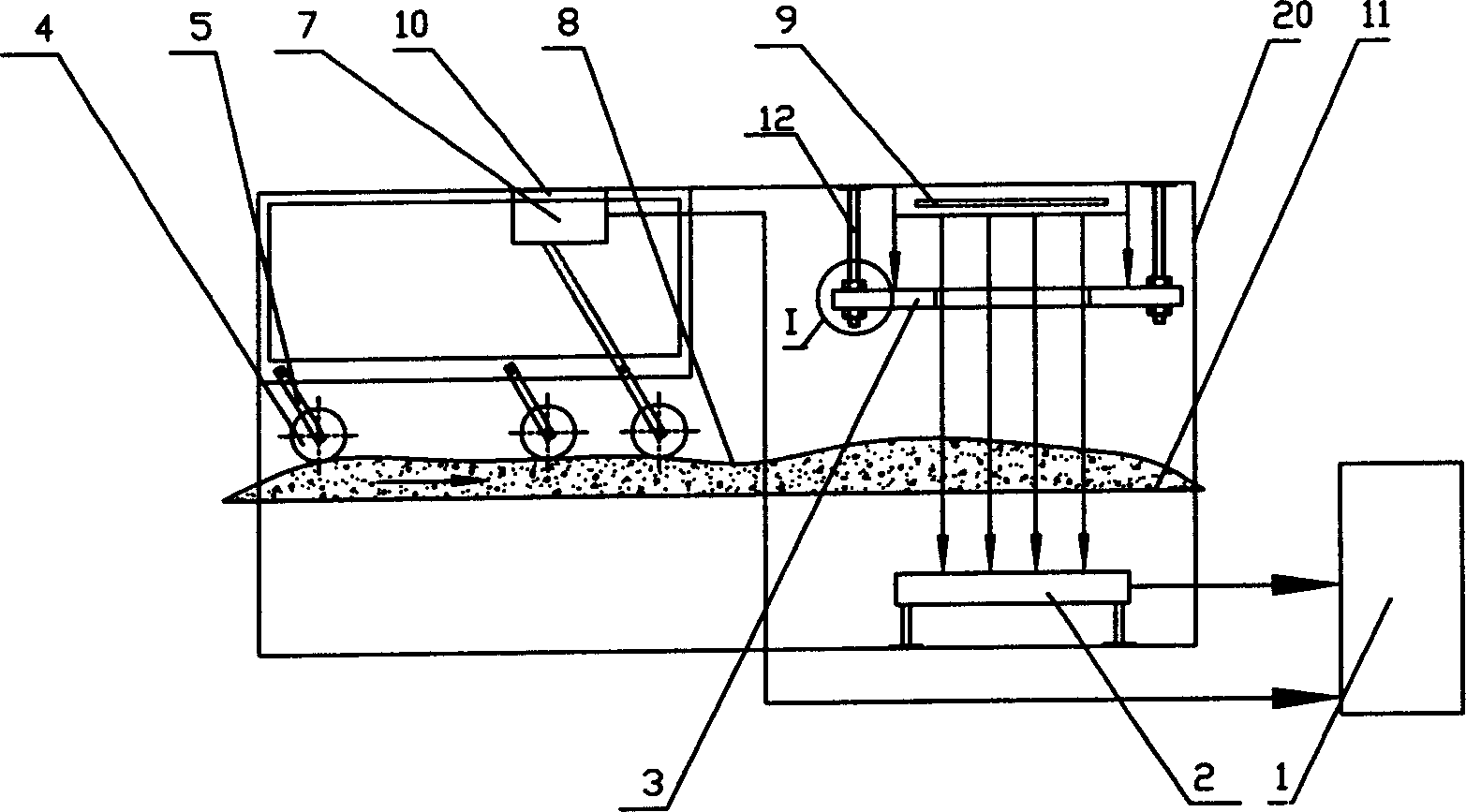

[0055] exist figure 1 In the present invention, in order to make the radiation source 9 and the gamma ray detector 2 only give the shredded tobacco weight that the pressure roller has passed, the radiation source 9 and the gamma ray detector 2 are installed on the upper and lower sides of the upper belt 11 of the belt conveyor, and Place it behind the pressure roller 4 so that the centerlines of the radioactive source 9 and the gamma-ray detector 2 are parallel to each other and in a plane, which is perpendicular to the upper belt 11, and the intersection line between the plane and the upper belt should be in line with the pressure roller 4 The centerlines of the pressed tobacco streams coincide.

[0056] Secondly, a gamma-ray shielding plate 3 is placed above the gamma-ray detector 2, and there is a rectangular hole with a width of D and a length of L, where D and L are respectively related to the width of the pressure roller 4 and the width of the gamma-ray detector 2 The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com