Method for purifying waste gas containing water soluble organism

A water-soluble organic matter and exhaust gas technology, which is applied in chemical instruments and methods, combustion methods, separation methods, etc., can solve the problems of exhaust gas pollution and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

[0016] A polyester production plant emits waste gas, and its waste gas discharge volume is 1000-10000m 3 / h; Exhaust gas contains acetaldehyde, paraldehyde, ethylene glycol, 2-methyl-1,3-dioxolane and other substances, of which acetaldehyde and 2-methyl-1,3-diox The pentane ring is the main one, and its total hydrocarbons range from 3000 to 20000 μl / l. Use a fan to draw the exhaust gas out, and after passing through the absorption homogenizer, ethylene glycol is completely absorbed, and acetaldehyde and 2-methyl-1,3-dioxolane are homogenized in concentration; after preheating to a certain temperature, It enters the catalytic combustion reactor and is completely oxidized and discharged under the action of the catalyst. Table 1 is the operating conditions and treatment results of Examples 1 to 8, wherein the catalytic combustion catalyst in Examples 1 to 4 is a honeycomb catalyst containing Pt 0.26wt%, Pd 0.13wt%, and the catalytic combustion catalyst in Examples 5 to 8 It is ...

Embodiment 9

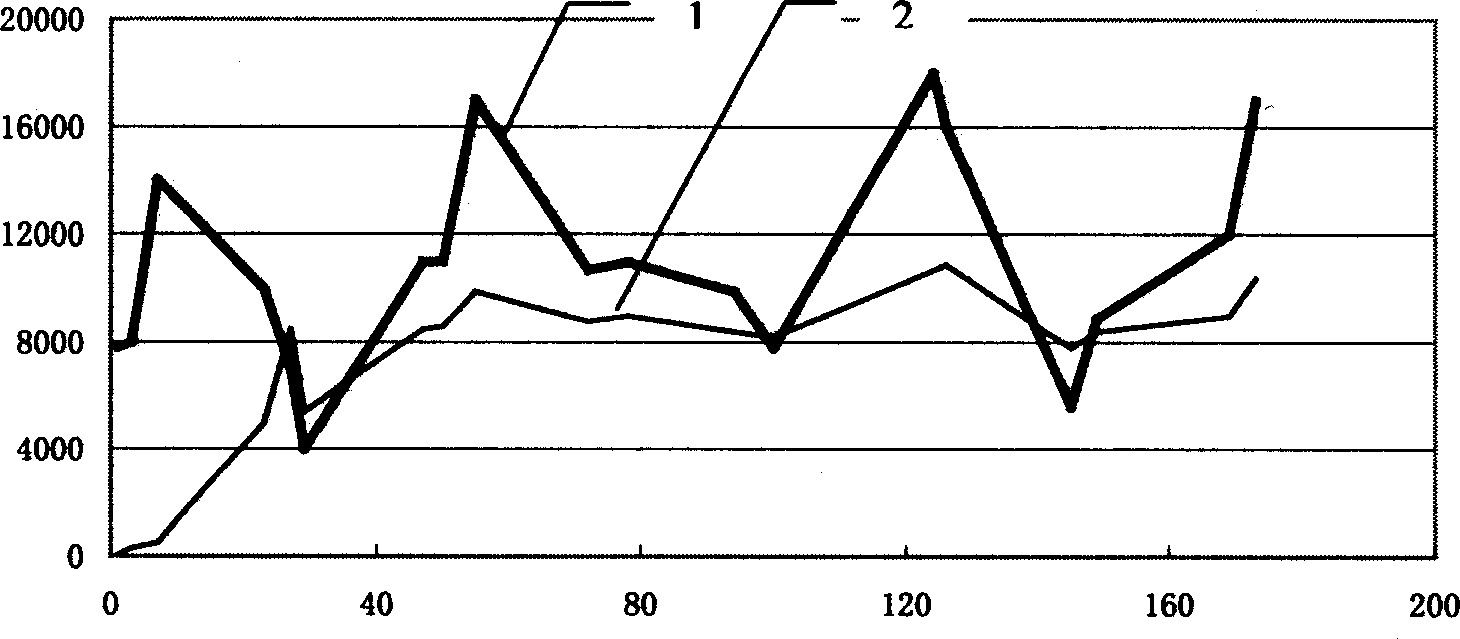

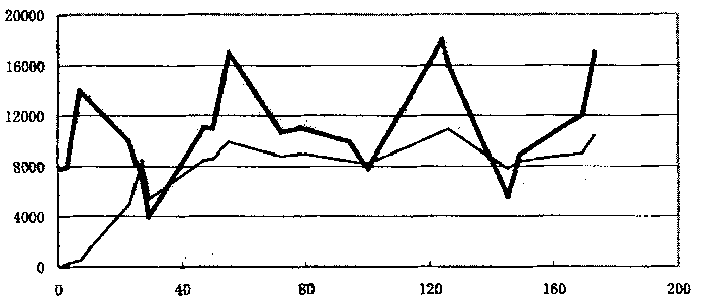

[0018] This example illustrates the homogenization effect of the homogenizing absorber, the homogenization results are shown in figure 1 , the homogenization effect is obvious.

[0019] implement

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com