Device and method for preparing tissue engineering supporting materials by electric spinning

A tissue engineering scaffold and electrospinning technology, which is applied in the field of biomedical material preparation, can solve the problems of large-scale industrial application of equipment and complex structure of equipment, and achieve the effect of high porosity, simple equipment and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

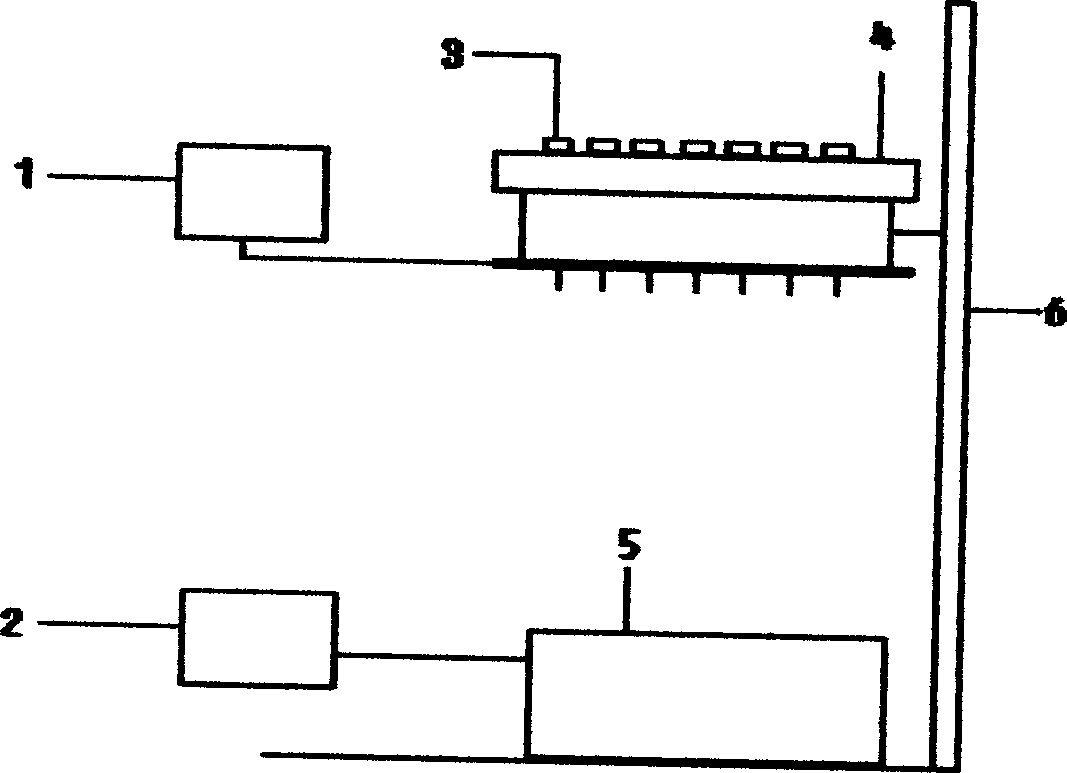

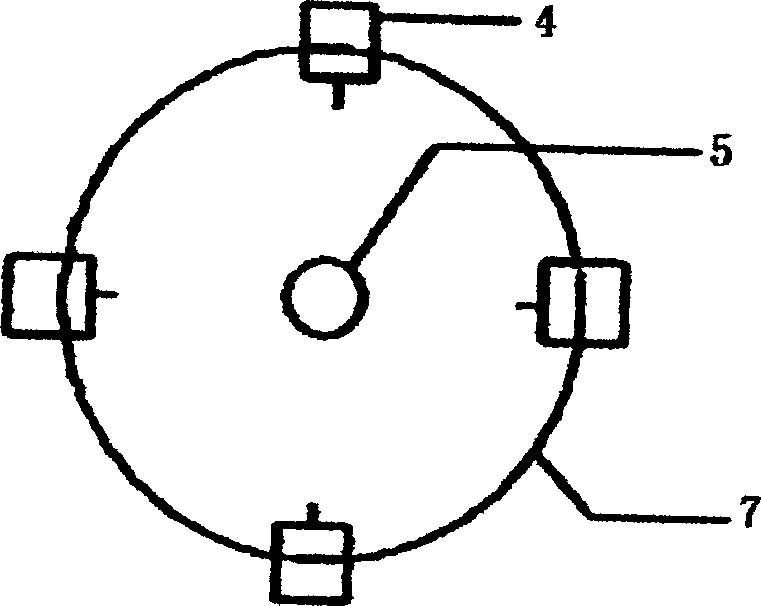

Method used

Image

Examples

Embodiment 1

[0043] 1. Prepare a chloroform solution with a mass concentration of 1% PHBV and place it in a liquid storage device;

[0044] 2. Install a metal plate as a collection device;

[0045] 3. Install the pneumatic feeding device, adjust the air pressure so that the liquid droplets appear at the nozzle without dripping;

[0046] 4. Adjust the distance from the nozzle to the collection device to 10cm;

[0047] 5. Turn on the high-voltage power supply, adjust the voltage to 10kV, and start spinning.

Embodiment 2

[0049] 1. Prepare a chloroform solution with a mass concentration of 10% PHBV and place it in a liquid storage device;

[0050] 2. Install a conductive roller as a collection device, and set the speed at 10 rpm;

[0051] 3. Install pump feeding device;

[0052] 4. Adjust the distance from the nozzle to the collection device to 20cm;

[0053] 5. Turn on the high-voltage power supply, adjust the voltage to 20kV, and start spinning.

Embodiment 3

[0055] 1. Prepare a chloroform solution with a mass concentration of 5% PHBH and place it in a liquid storage device;

[0056] 2. Install liquid surface collection device;

[0057] 3. Install a high-level trough-type feeding device, and adjust the air pressure so that droplets appear at the nozzle without dripping;

[0058] 4. Adjust the distance from the nozzle to the collection device to 5cm;

[0059] 5. Turn on the high-voltage power supply, adjust the voltage to 15kV, and start spinning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com