Switch resistance drive device control

A switched reluctance motor and magnetic technology, applied in the direction of electromechanical devices, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of limiting motors, increasing winding loss, multi-space, etc., and achieve low loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

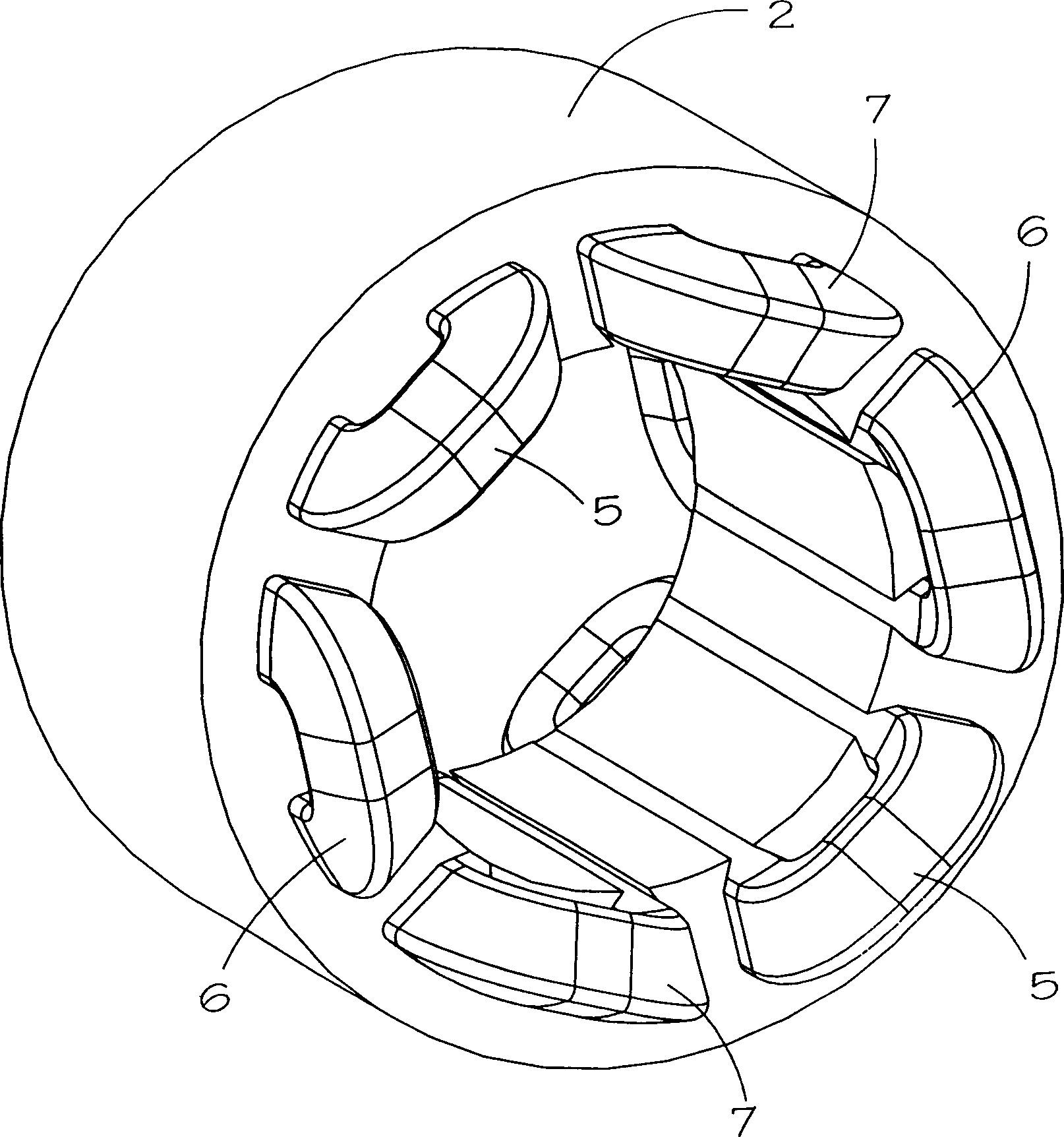

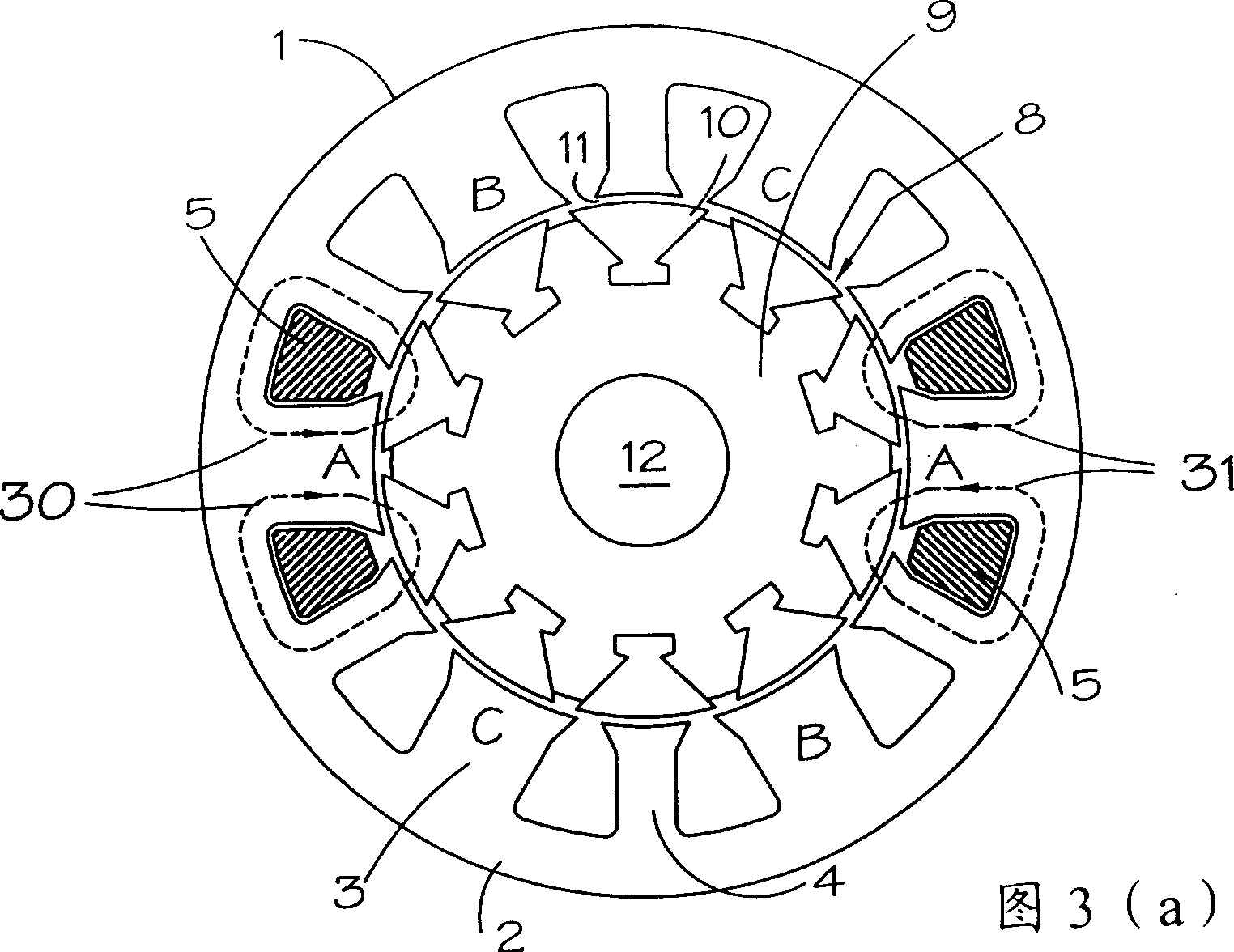

[0023] see figure 1 and 2 , a three-phase switched reluctance motor 1 comprises a stator 2 having a plurality of wider first stator poles 3 and narrower second stator poles 4 arranged alternately. In the illustrated embodiment, the stator 2 has six first stator poles 3 and six second stator poles 4 . Each first stator pole 3 is wound with a corresponding excitation coil 5, 6, 7 for the three phases. The coils are mounted in diametrically opposed coil pairs such that the diametrically opposed coil pairs are electrically connected to each other in series. In an alternative embodiment, completely diametrically opposed coils are connected in parallel.

[0024] The rotor 8 includes a magnetless core 9 . Ten magnetically separated rotor segments 10 of magnetic material are clamped in longitudinal keyways in core 9 so that they are circumferentially aligned and separated from stator poles 3 , 4 by air gaps 11 . The rotor segment 10 is arranged to direct the magnetic flux from a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com