Printer

A printer and print head technology, applied in printing and other directions, can solve the problems of overall complexity of the maintenance mechanism, difficulty in miniaturization, increase in device size, etc., and achieve the effects of reduced width size, low cost, and improved flexible installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] First, preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

[0066] A printer in an embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

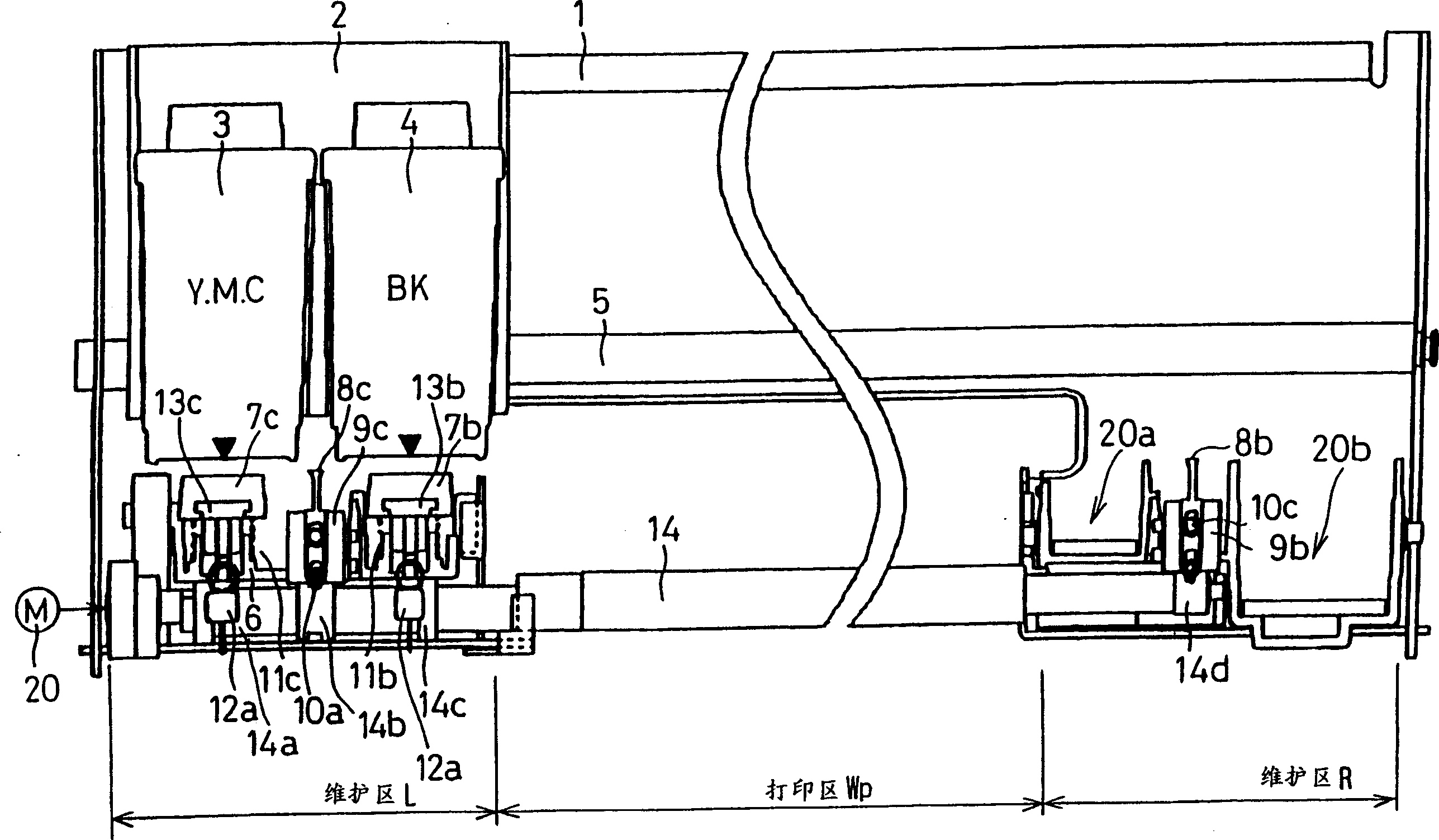

[0067] figure 1 is the front view of the printer. The printer is constructed as a dual printhead type serial printer with two printheads 3 and 4, the printhead 3 being used to represent the three main colors used for color recording: yellow (Y); magenta (M); Cyan (C), and another printhead 4 is used to represent black (BK). The two print heads 3 and 4 are detachably connected to the carriage 2 guided by the carriage shaft 5 . The carriage shaft 5 is horizontally suspended on the main frame 1 . By moving carriage 2 from left to right or vice versa, such as figure 1 As shown, the print heads 3 and 4 reciprocate relative to a recording medium (not shown) in the main scanning direction. As seen in the figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com