Landing gear apparatus and assembling method thereof

A landing gear and input shaft technology is applied in the field of a landing gear device supporting a semi-trailer, and a method for assembling a landing gear device bracket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Detailed description of the preferred embodiment

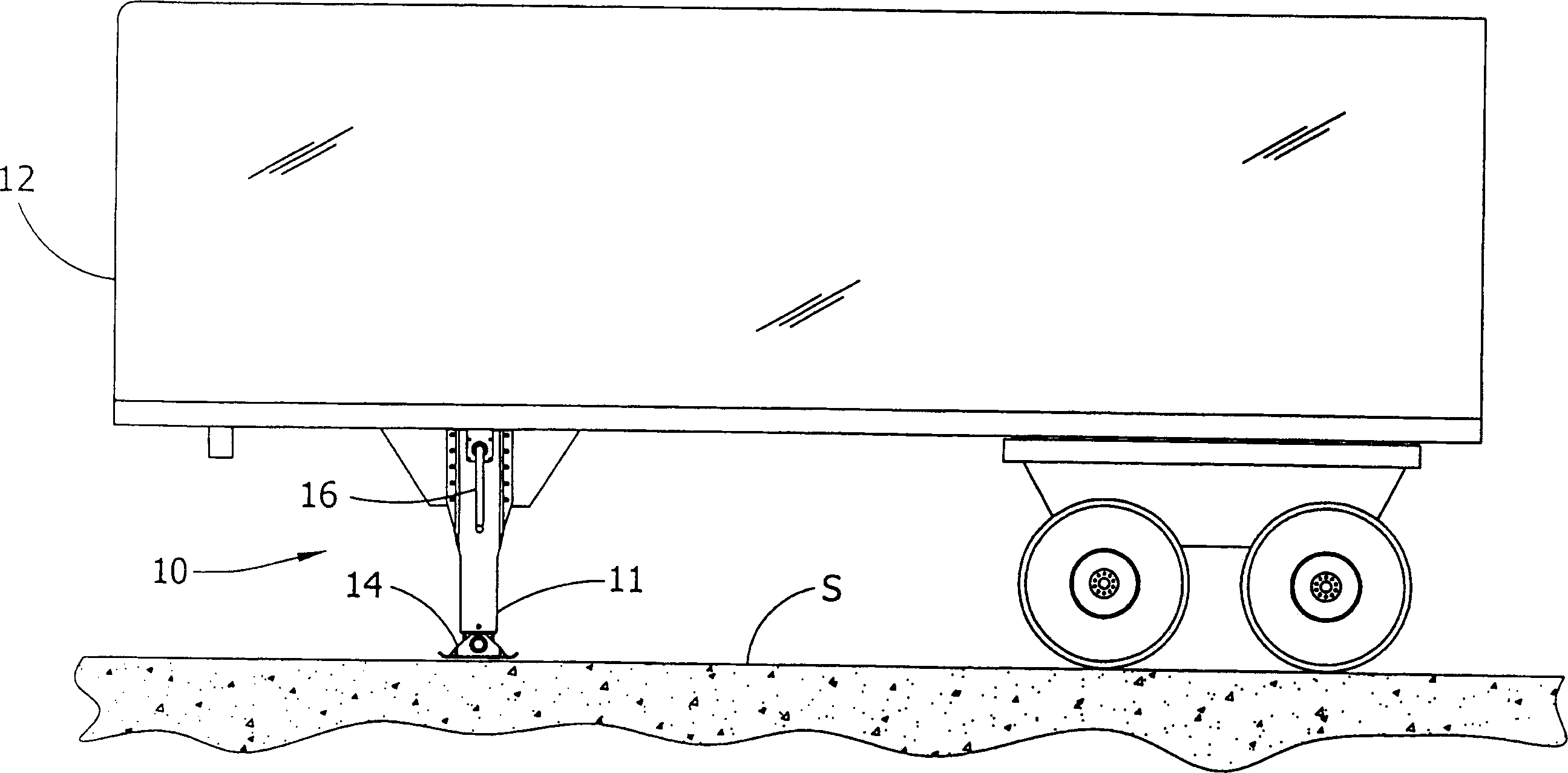

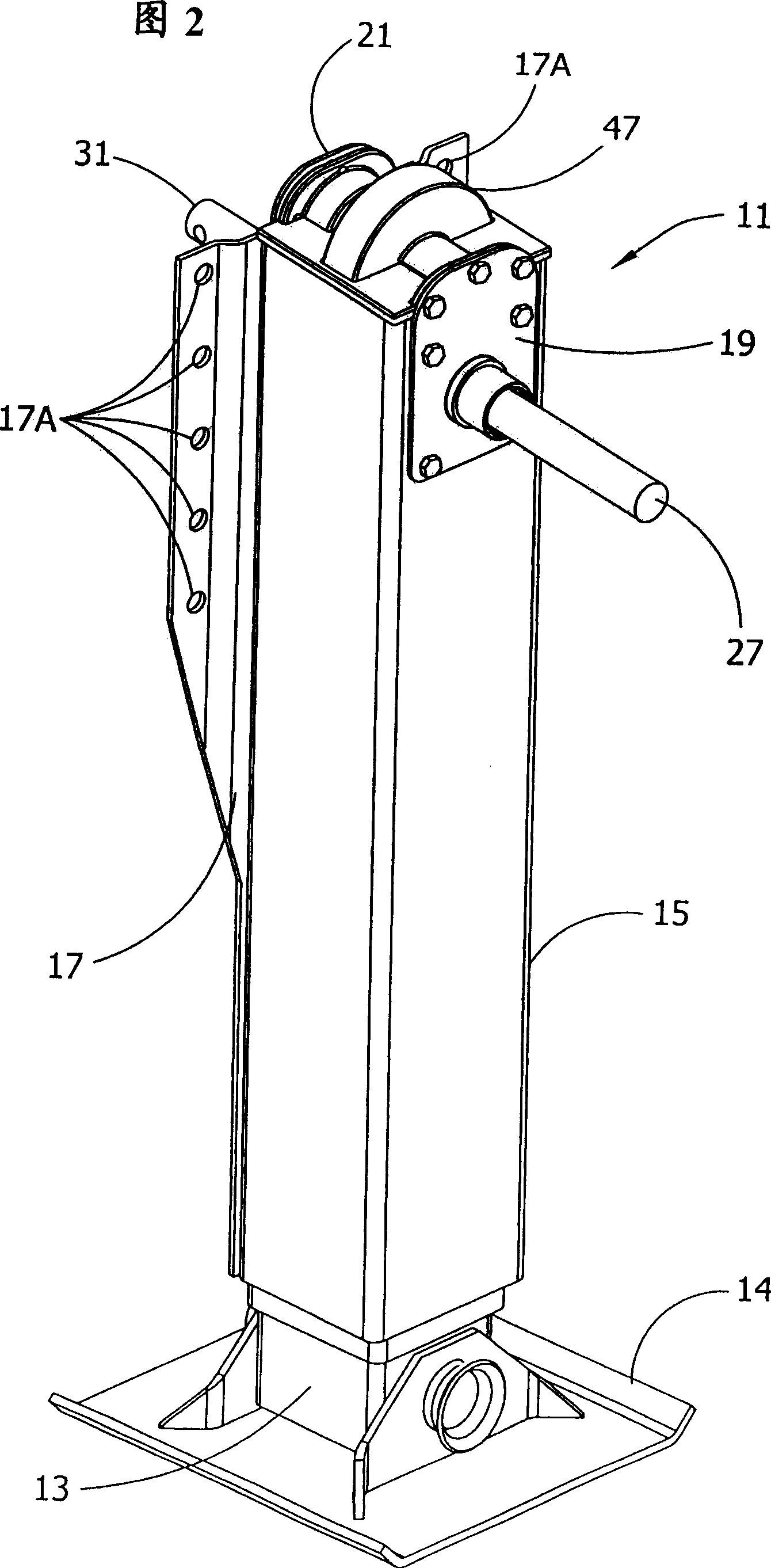

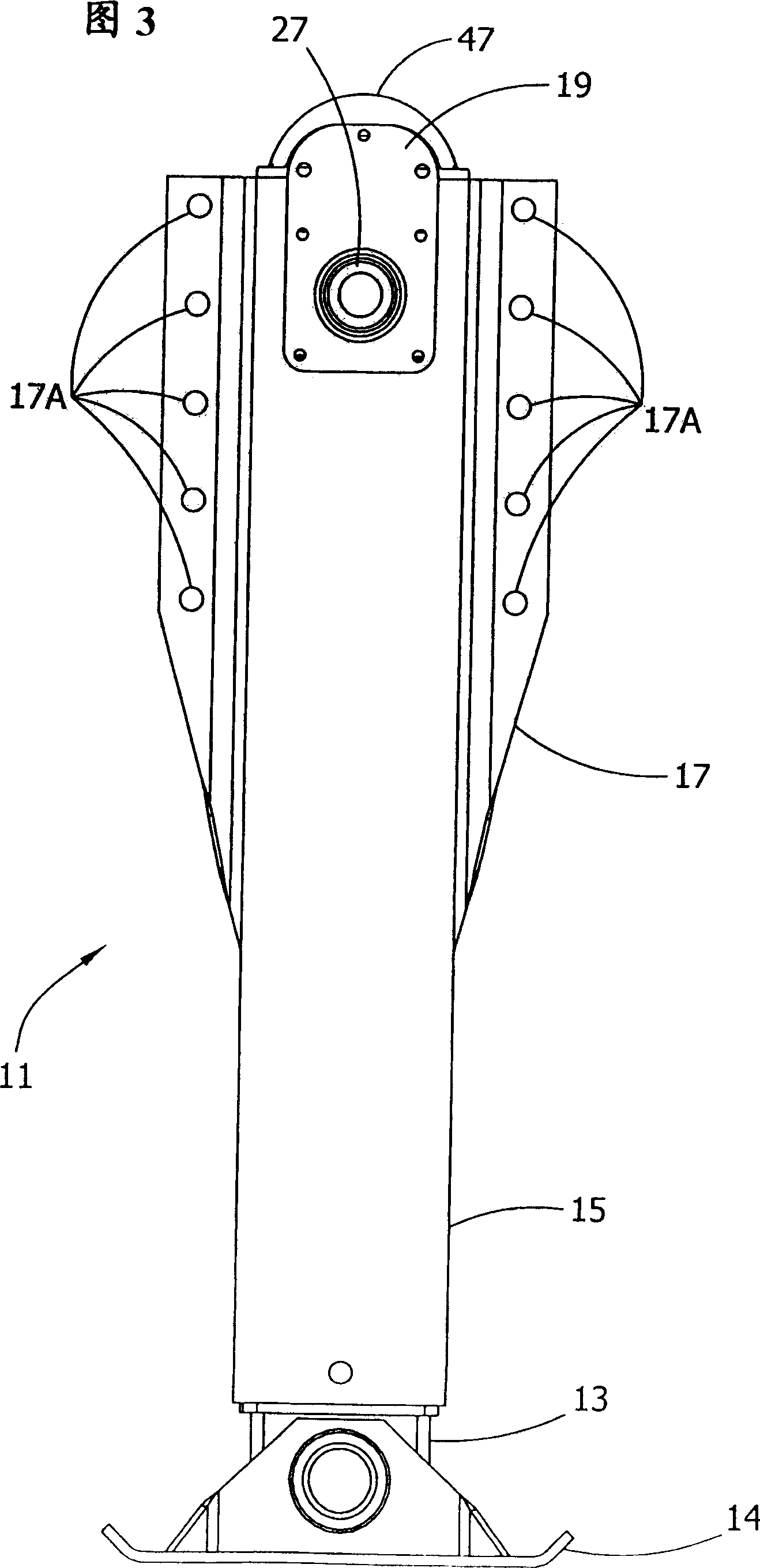

[0044] figure 1 Illustrates the undercarriage, generally indicated at 10, for supporting the semi-trailer when the semi-trailer is not coupled to a tractor. The landing gear arrangement 10 generally includes a pair of brackets 11 (only one bracket is shown) respectively located at the front corners of the semi-trailer 12 . As is well known, each bracket 11 can be extended to engage the road surface S or other supporting surface, thereby holding the front of said semi-trailer. The foot 14 of the undercarriage 10 is pivotally mounted on the bracket 11 and engages with the road surface S. As shown in FIG. When the above-mentioned semi-trailer 12 is dragged on the ground by a tractor (not shown), the bracket 11 can also be retracted to leave the ground. The crank handle 16 is generally used to extend and contract the length of the above-mentioned bracket 11, as will be described below. The following description is limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com