Multi-layer plane ionization chamber for measuring boundary dosage distribution of different material

A technology of dose distribution and ionization chamber, which is applied in measuring devices, radiation measurement, X/γ/cosmic radiation measurement, etc. It can solve the problems of X-ray interface dose distribution that have not been reported in the literature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

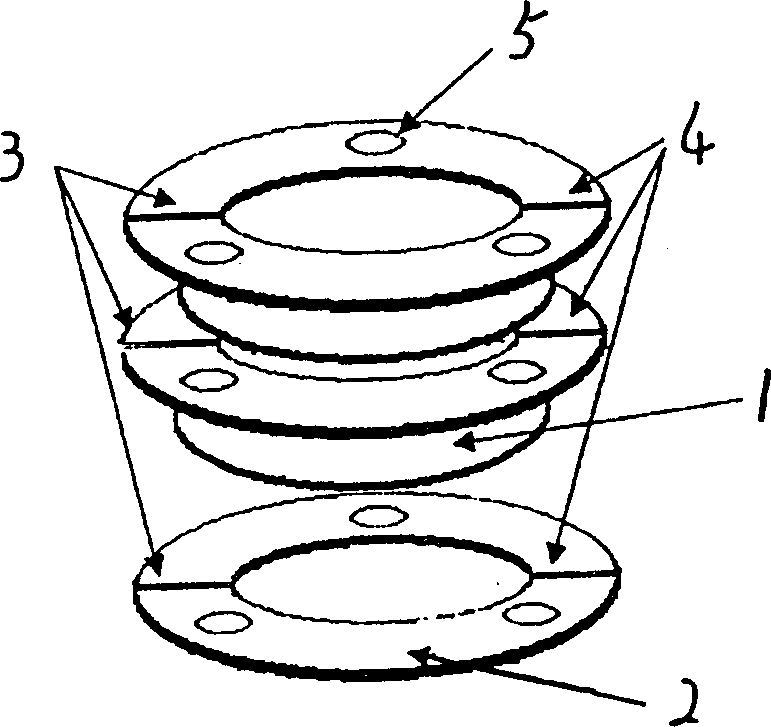

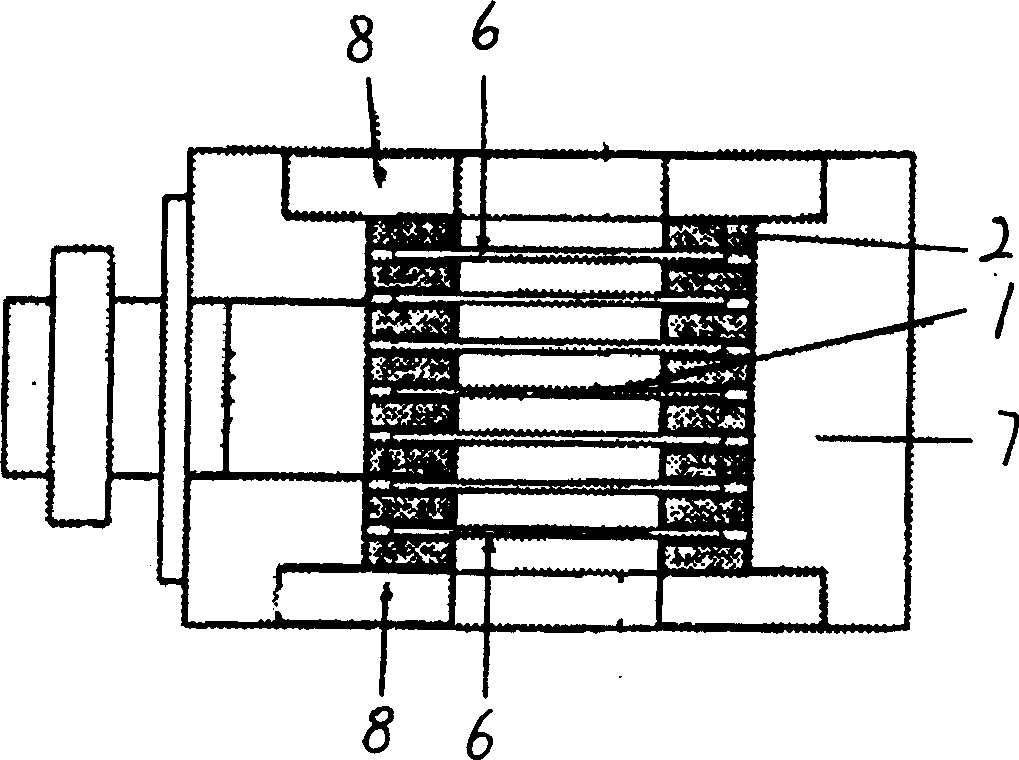

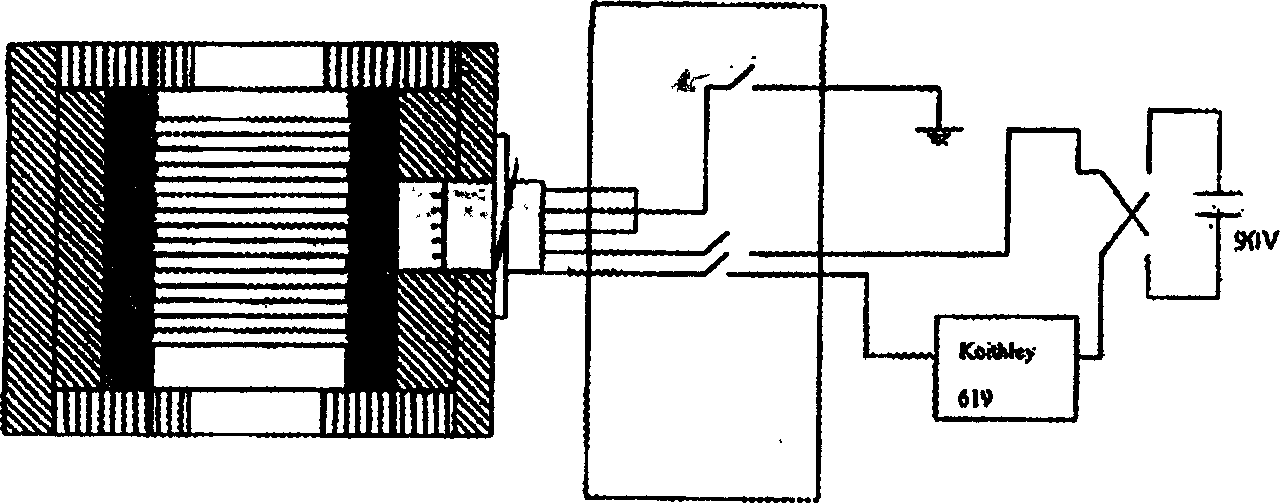

[0023] see figure 1 , figure 2 , image 3 , the multi-layer flat ionization chamber includes internal components, front and rear two-layer terminal plates and the shell. The electrode plate of the ionization chamber is made of high-purity aluminum foil with a thickness of 0.005mm, with a total thickness of 0.04mm and a total of eight layers, which are pasted with epoxy resin On the plexiglass ring and connected with the outgoing wire of the copper wire slot on the ring, it is drawn out through a multi-head socket. The thickness of the plexiglass ring is 1.0mm, the inner diameter is 30mm, and the outer diameter is 70mm. There is a ventilation groove with a width of 1.0mm and a depth of 0.3mm on each ring, so that the cavity communicates with the atmosphere. Use three plexiglass bolts with a diameter of 6mm to fix all the annular insulating plates with electrode plates in a certain order to form the internal components of the ionization chamber. The front and rear end plates...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com