Method and device for testing printed circuit boards with a parallel tester

A printed circuit board, test printing technology, applied in the directions of printed circuit, printed circuit manufacturing, printed circuit testing, etc., can solve problems such as wrong measurement, slow connector tester, and test probes that cannot be close to each other.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

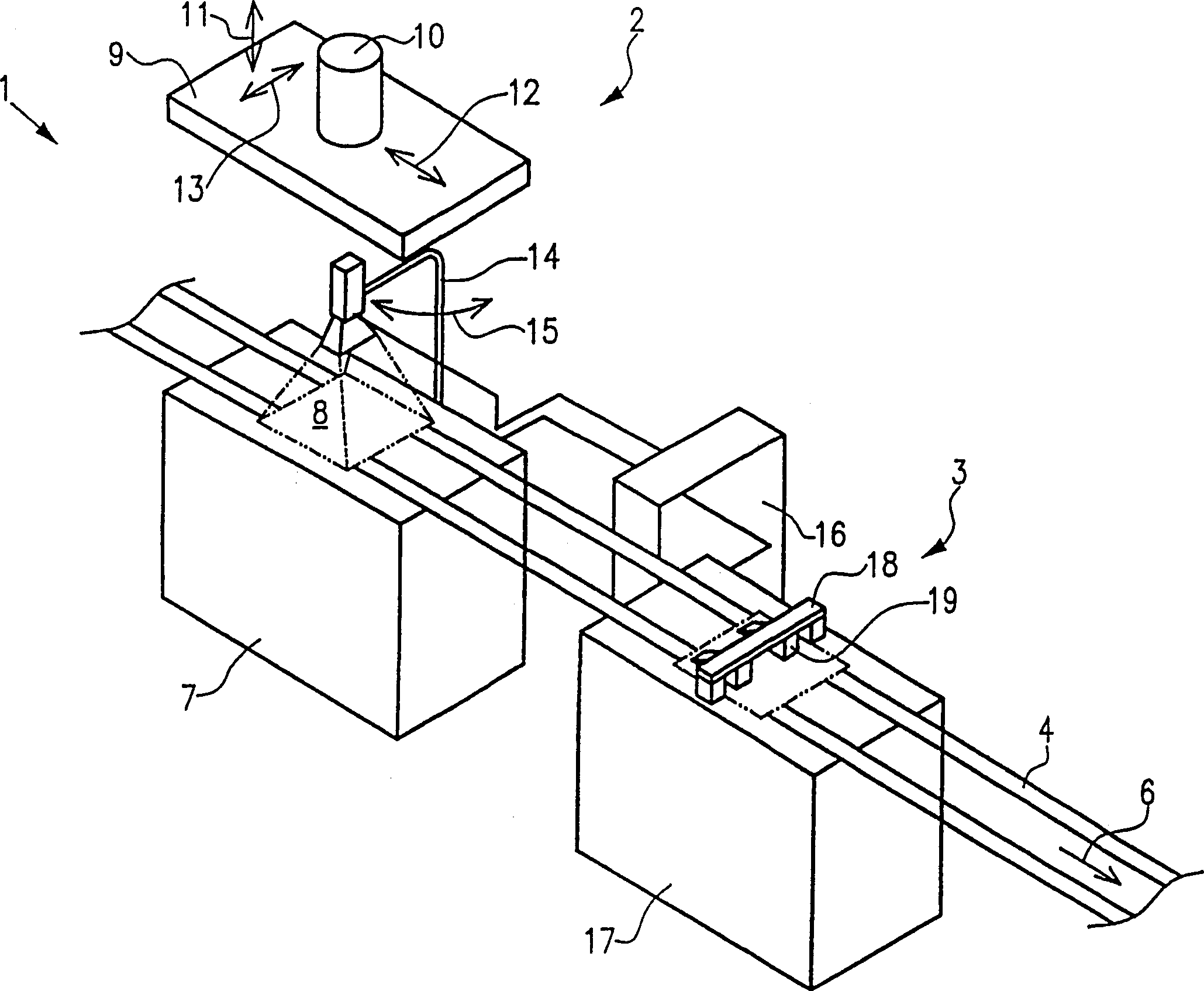

[0050] figure 1 is shown schematically an apparatus according to the invention for testing printed circuit boards. The device 1 has a parallel tester 2 and a joint tester 3 . The parallel tester 2 and the joint tester 3 are connected by a conveyor 4 , which is formed by two conveyor belts 5 in this embodiment. With the conveyor 4, the printed circuit boards to be tested can be transferred in the transfer direction 6 from a substantially known but not shown separation station to the parallel tester 2 and from the parallel tester 2 to the joint tester 3, and From the splice tester 3 it is conveyed to a generally known but not shown collection station.

[0051] The parallel tester 2 has a main body 7 with a mounting area 8 on the top for fixing a printed circuit board to be tested. When both sides of the circuit board are to be tested, the mounting area 8 is provided with an adapter having contact elements for contacting the circuit board test points. Facing the mounting area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com