Mechanical intermeshing driven stepless gear

A continuously variable transmission and mechanical technology, which is applied in the direction of mechanical equipment, transmission devices, belts/chains/gears, etc., can solve the problem of increasing the labor intensity of the driver, transmission efficiency and work reliability that cannot meet the requirements of automobile performance, and reduce the engine speed. and the service life of drive train parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

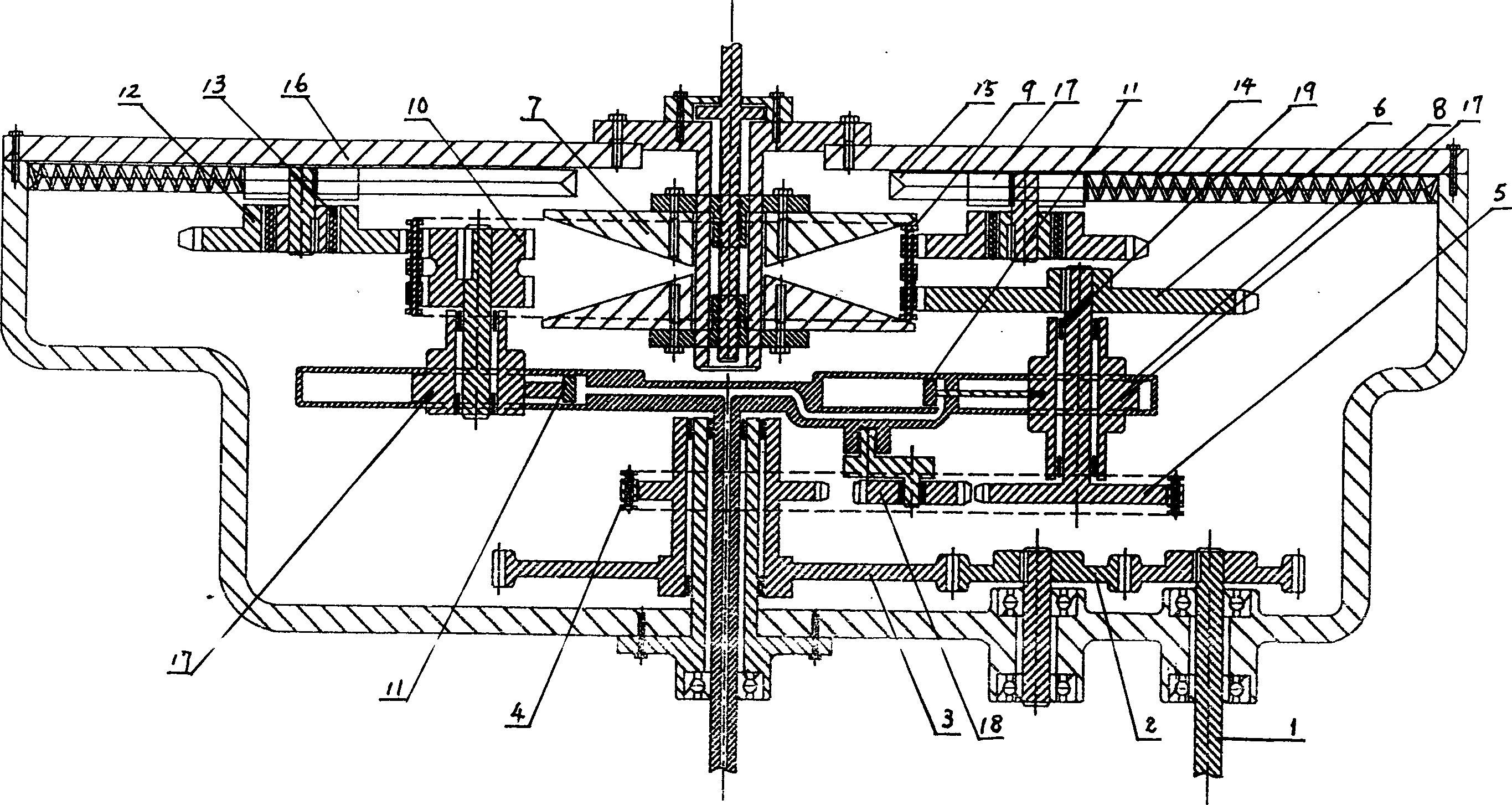

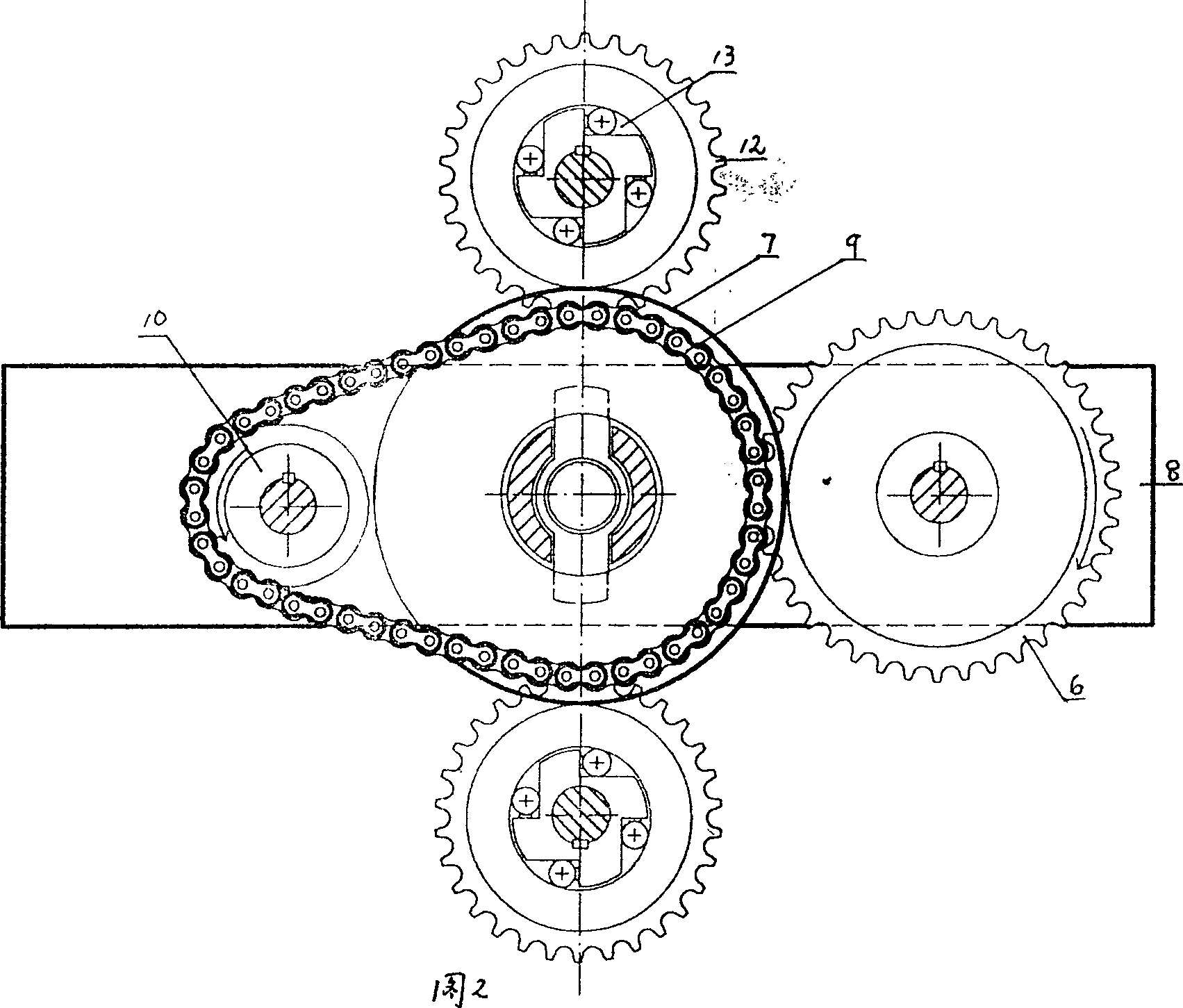

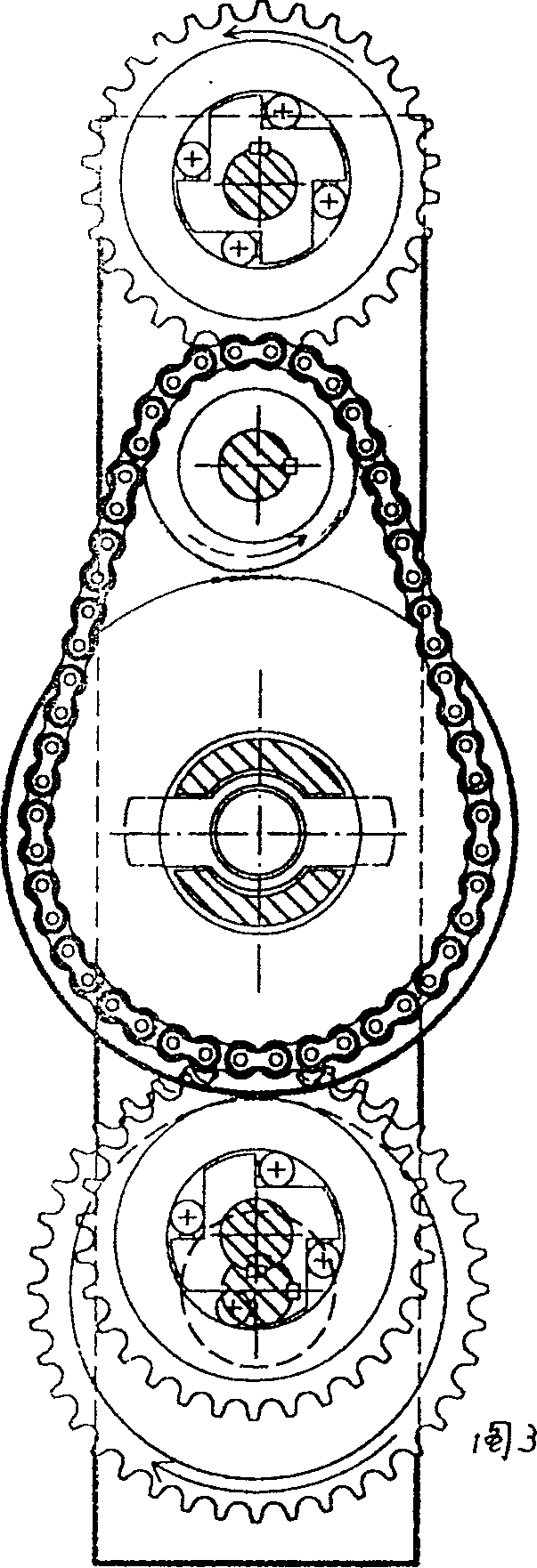

[0011] please see figure 1 - Fig. 6, each component and the connection relationship among them have been as above. The power is input by the power input shaft 1, through the intermediate gear 2, the driving sprocket 3, the transmission chain 4, and the driven sprocket 5 drives the outer meshing planetary sprocket 6 coupled with it to rotate around the variable radius wheel 7, thereby pushing the movable The variable radius rotating arm 8 and the integrated power output shaft connected with it rotate so as to output power. The speed and torque at which the outer meshing planetary sprocket 6 rotates around the variable radius wheel 7 and the variable radius rotating arm 8 and the power output shaft rotate for a week are related to the radius of the variable radius wheel 7 at that time. When the variable radius wheel 7 is at the maximum radius, the outer meshing planetary sprocket 6 has the longest circumference around it, and is at the two ends of the variable radius arm 8. At ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com