Variable turbocharger

A turbocharger, variable technology, applied in the direction of mechanical equipment, combustion engines, machines/engines, etc., can solve problems such as difficulty, loose and small adjustment of connecting rod joints, complex structure, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, embodiments of the variable turbocharger according to the present invention will be described in detail with reference to the drawings.

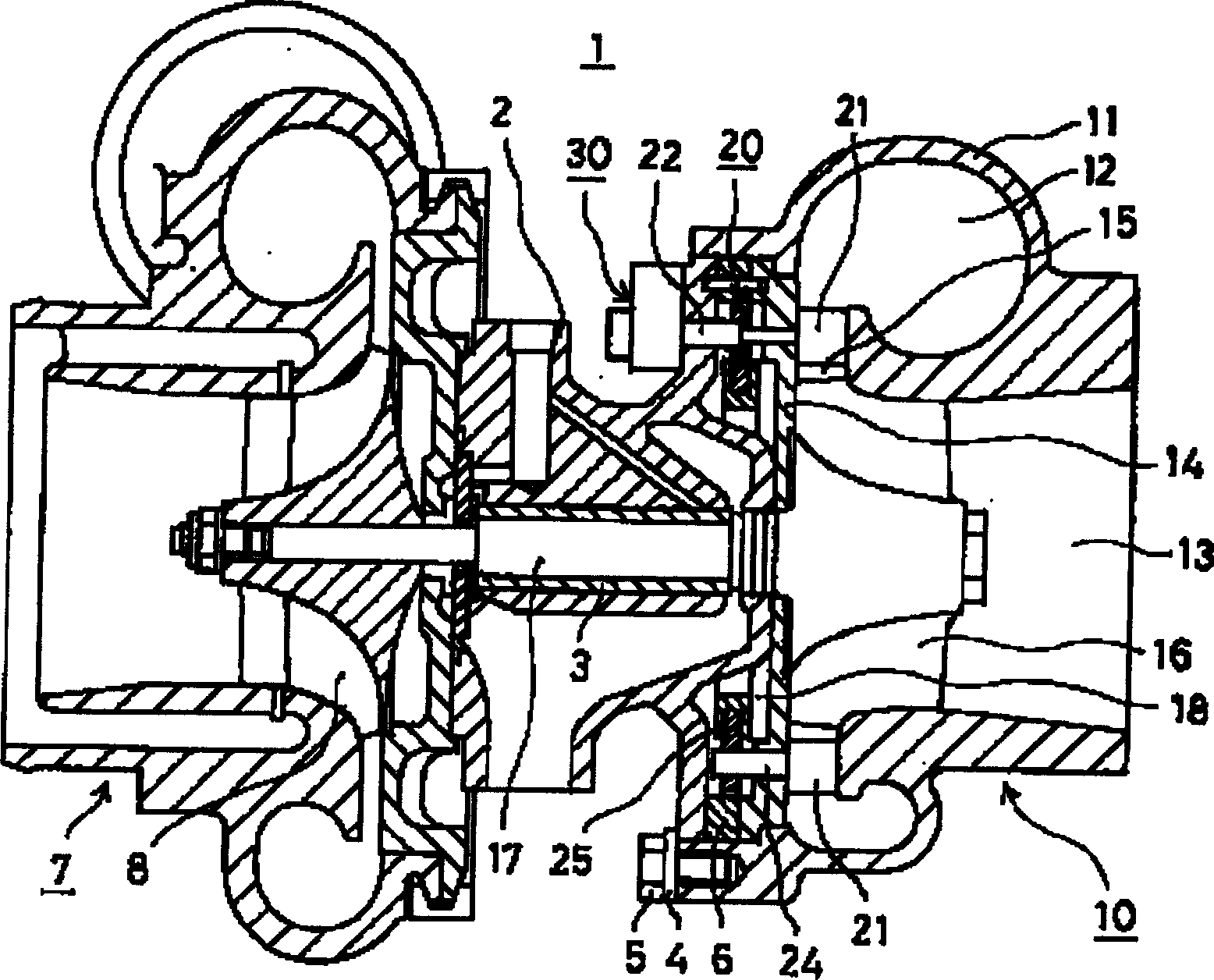

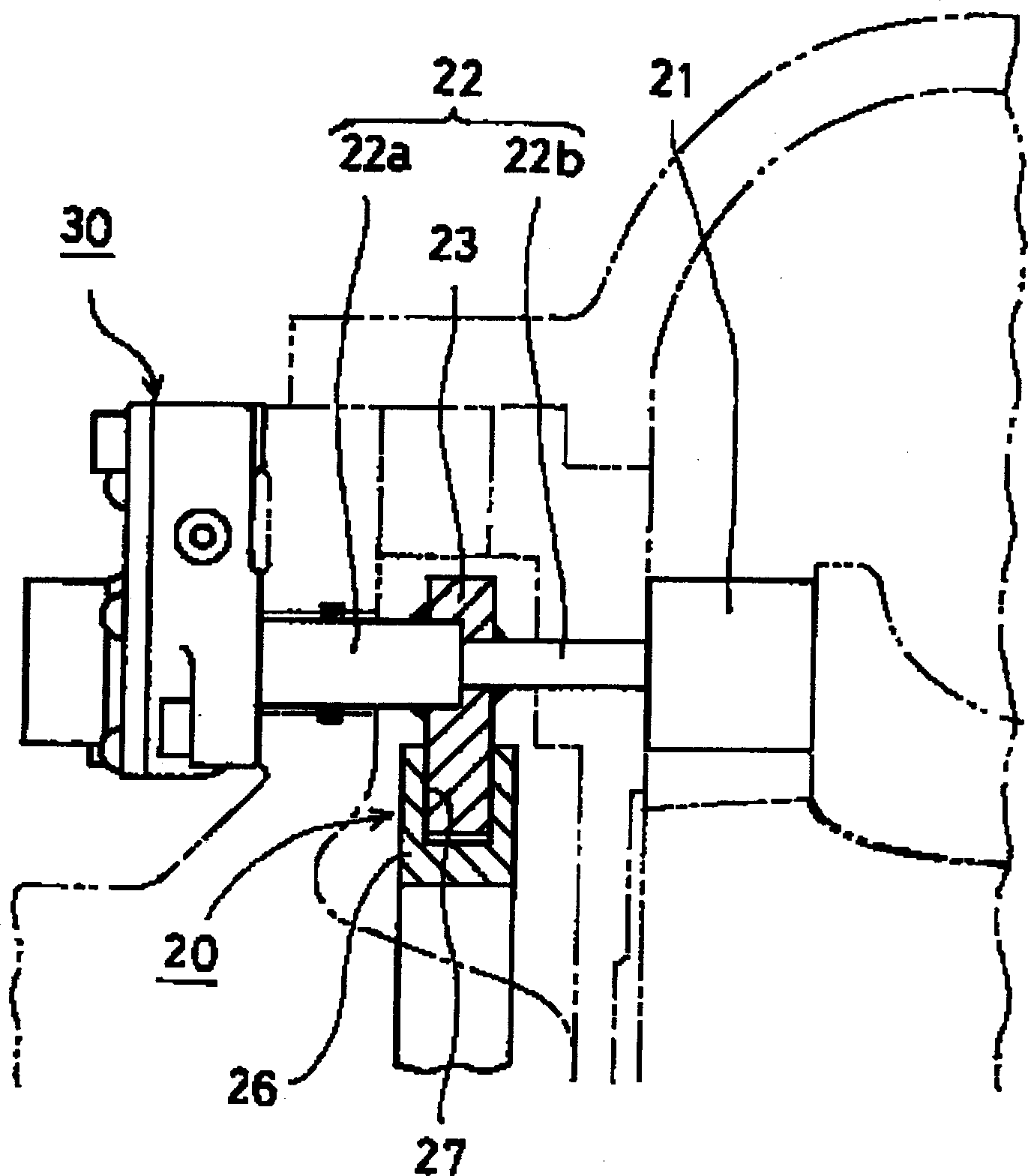

[0030] figure 1 It is a side sectional view of the variable turbocharger 1 . exist figure 1 Among them, a variable turbocharger 1 is composed of an air supply compressor and an exhaust turbine 10 .

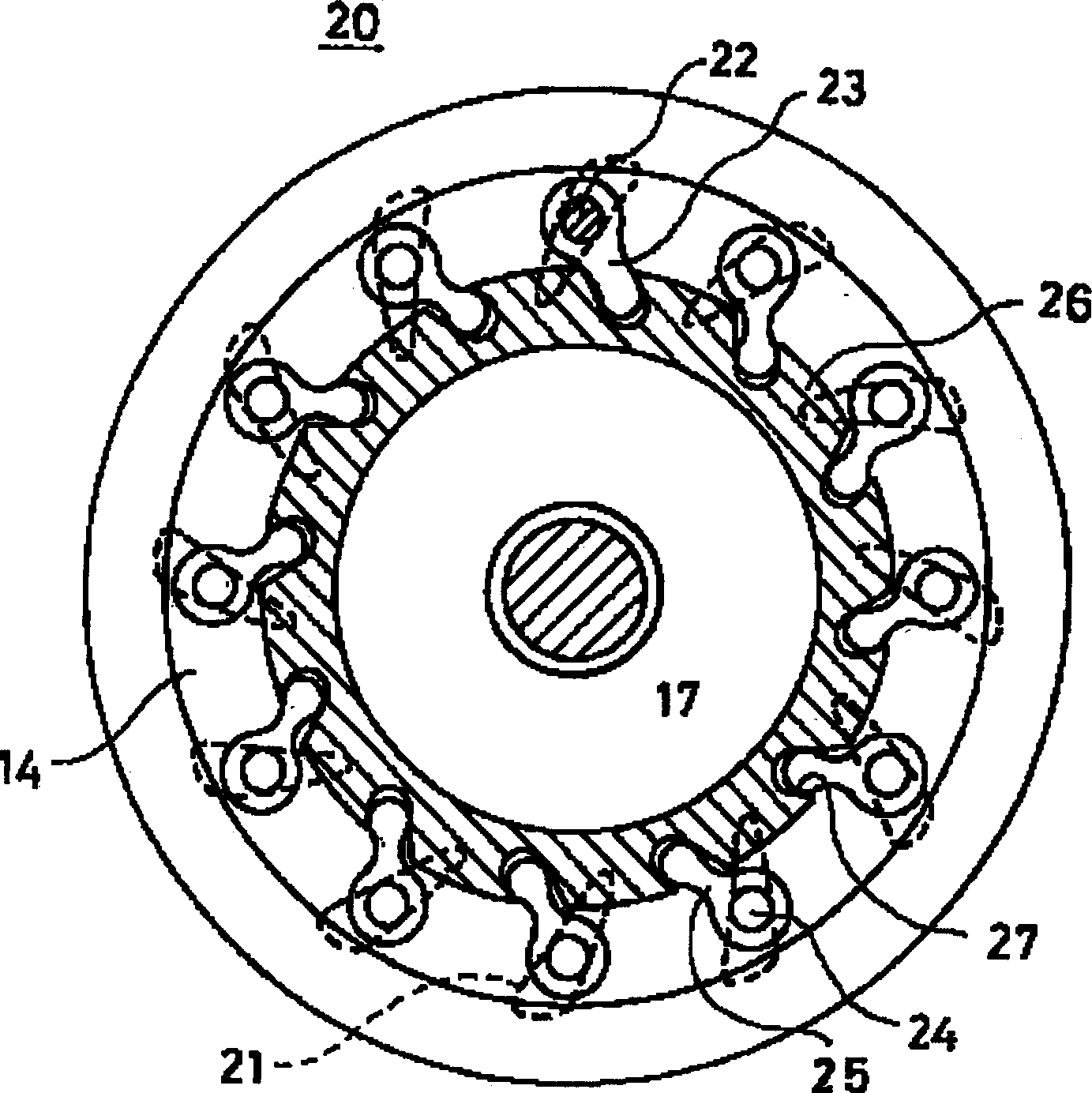

[0031] The exhaust turbine 10 is provided in the middle of an exhaust flow path of an engine not shown in the figure, and has an exhaust-side casing 11 that guides the inflow and outflow of exhaust gas, and an exhaust-side casing 11 that houses an exhaust-side casing 11. .

[0032] The exhaust-side casing 11 has an exhaust gas inflow portion 12 integrally formed on the outer peripheral side and a substantially cylindrical exhaust gas outflow portion 13 formed in the central portion. Inside the exhaust side housing 11, an exhaust side inner plate 14 is provided to block the opening on the side opposite to the exhaust gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com