Strain tuning optical fiber grating sensing demodulator

A sensor demodulator and fiber grating technology, applied in the fields of fiber optic sensing, optical measurement, and wavelength tuning of optical devices, to achieve good market prospects, easy instrumentation, and stable and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

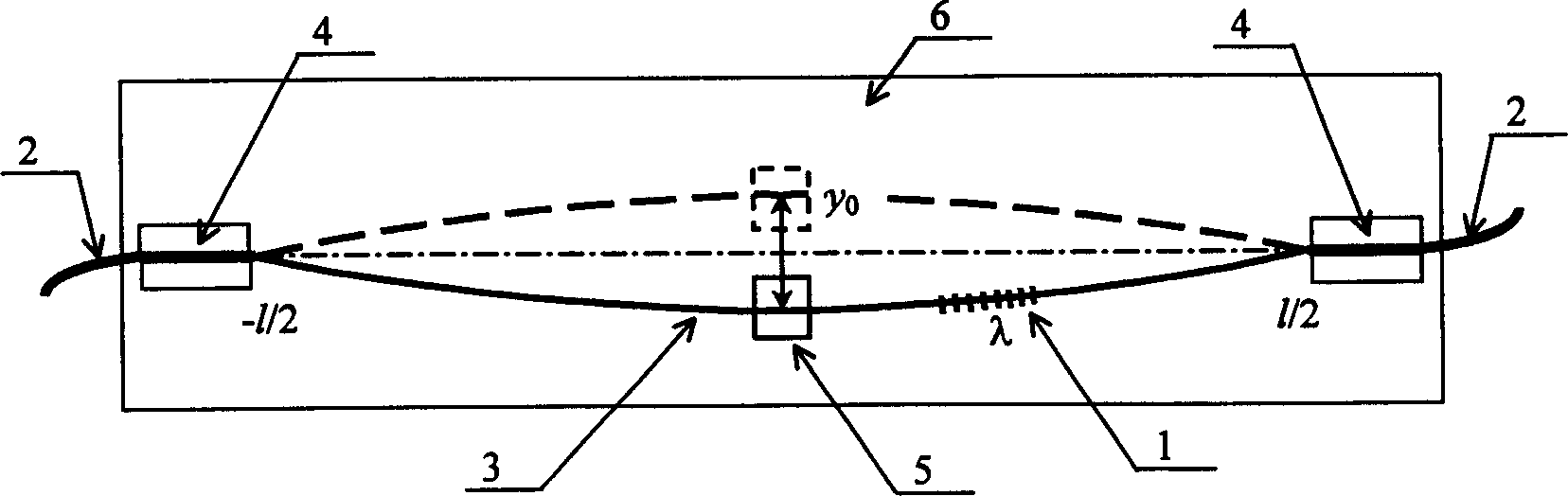

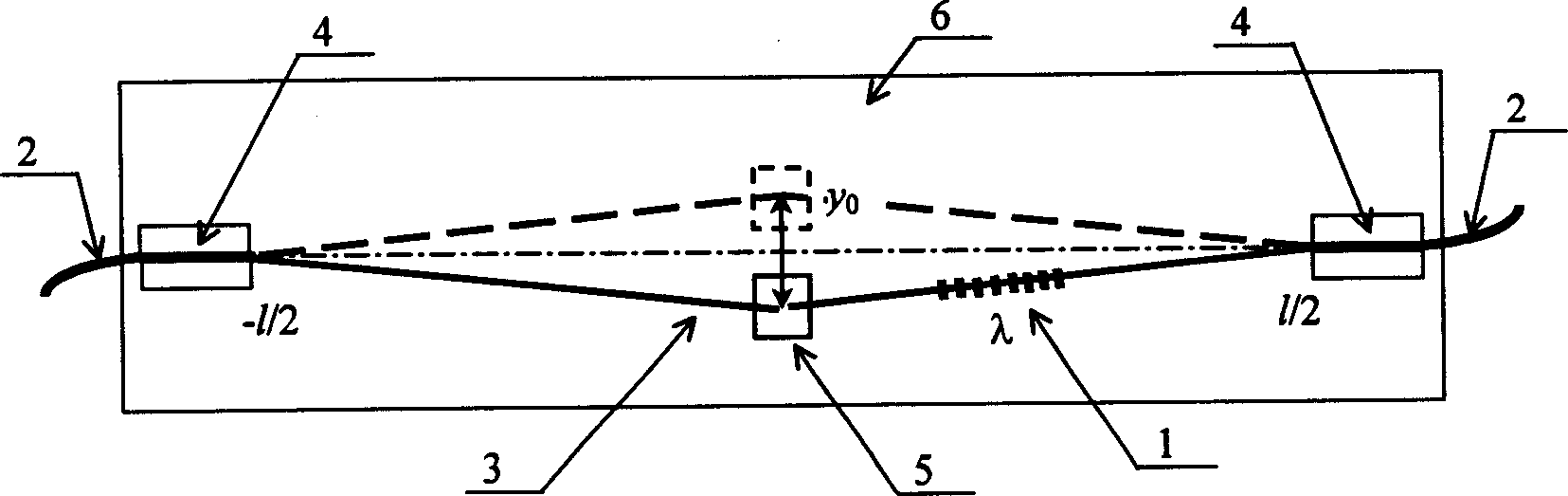

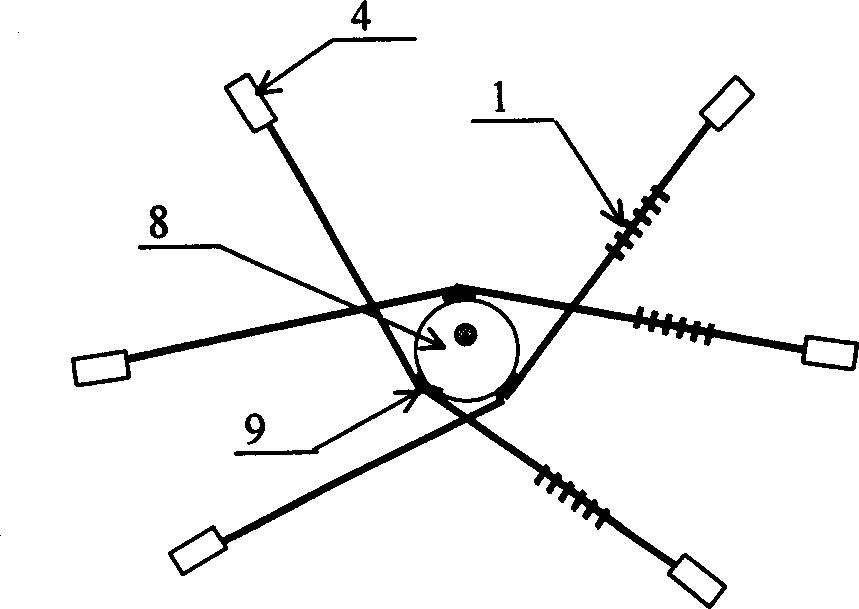

[0031] see first figure 1 and figure 2 , it can be seen from the figure that the strain-tuned fiber grating demodulator of the present invention can also be called a fiber grating lateral vibration tuning demodulator, which is composed of an optical fiber section 3 containing a fiber grating 1 and two ends 2 for fixing the optical fiber section 3 Two optical fiber holders 4, a vibrator 5 that drives the fiber segment 3 to vibrate transversely, and a casing 6 for installing and fixing the optical fiber holder 4 and the vibrator 5.

[0032] The component optical fiber 2 in the figure is a variety of optical fibers that have photorefractive properties and can be used to prepare gratings, including conventional communication optical fibers, high Ge-doped optical fibers, plastic optical fibers, and the like. The fiber grating 1 is a grating written by ultraviolet laser photorefractive method or other means. The optical fiber holder 4 is a mechanical fastener, which can be fasten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com