Drying installation with sheet-fed printing press

A drying device, sheet-fed technology, applied to printing machines, general parts of printing machinery, printing, etc., to achieve the effect of strengthening the drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

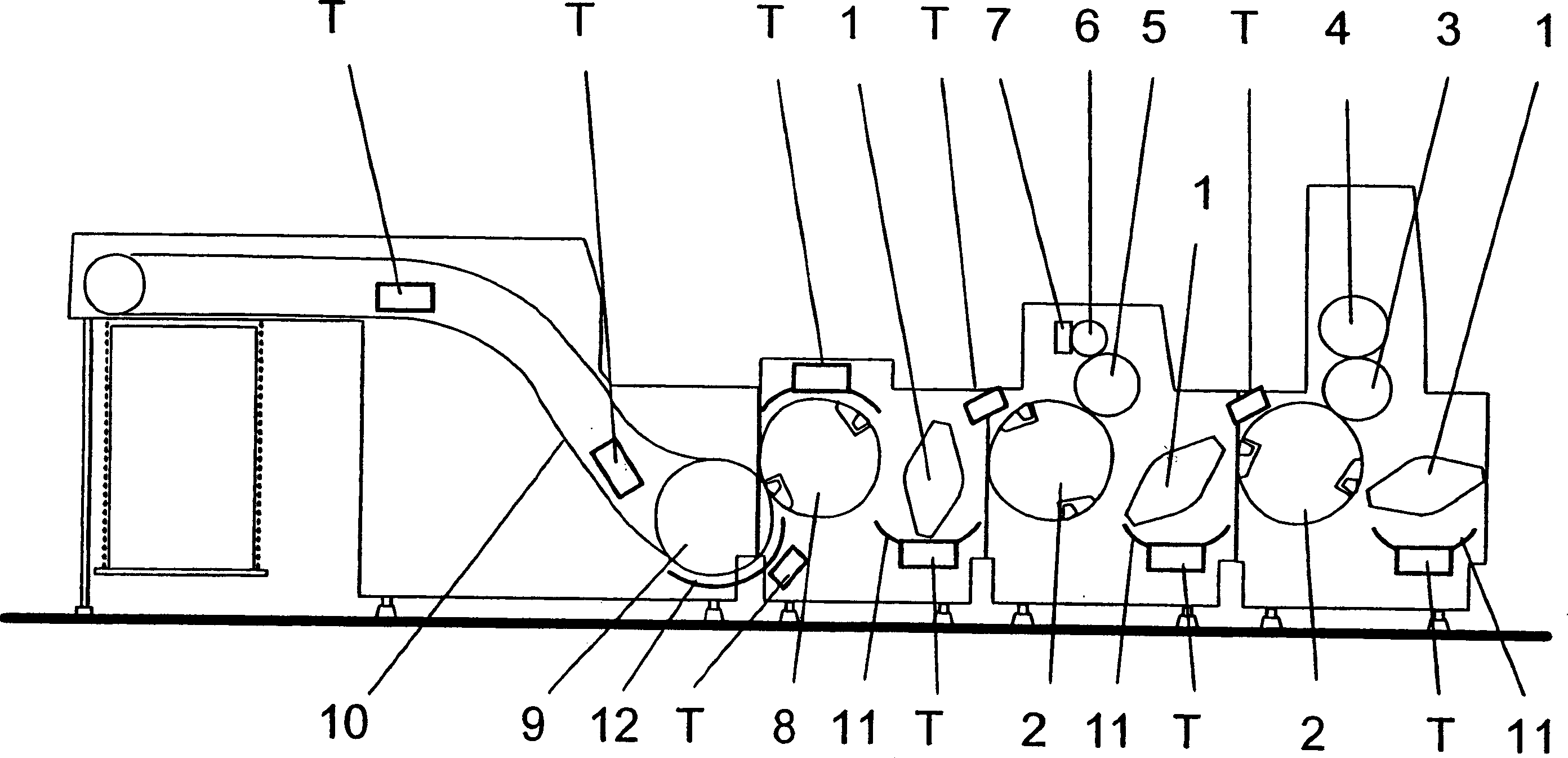

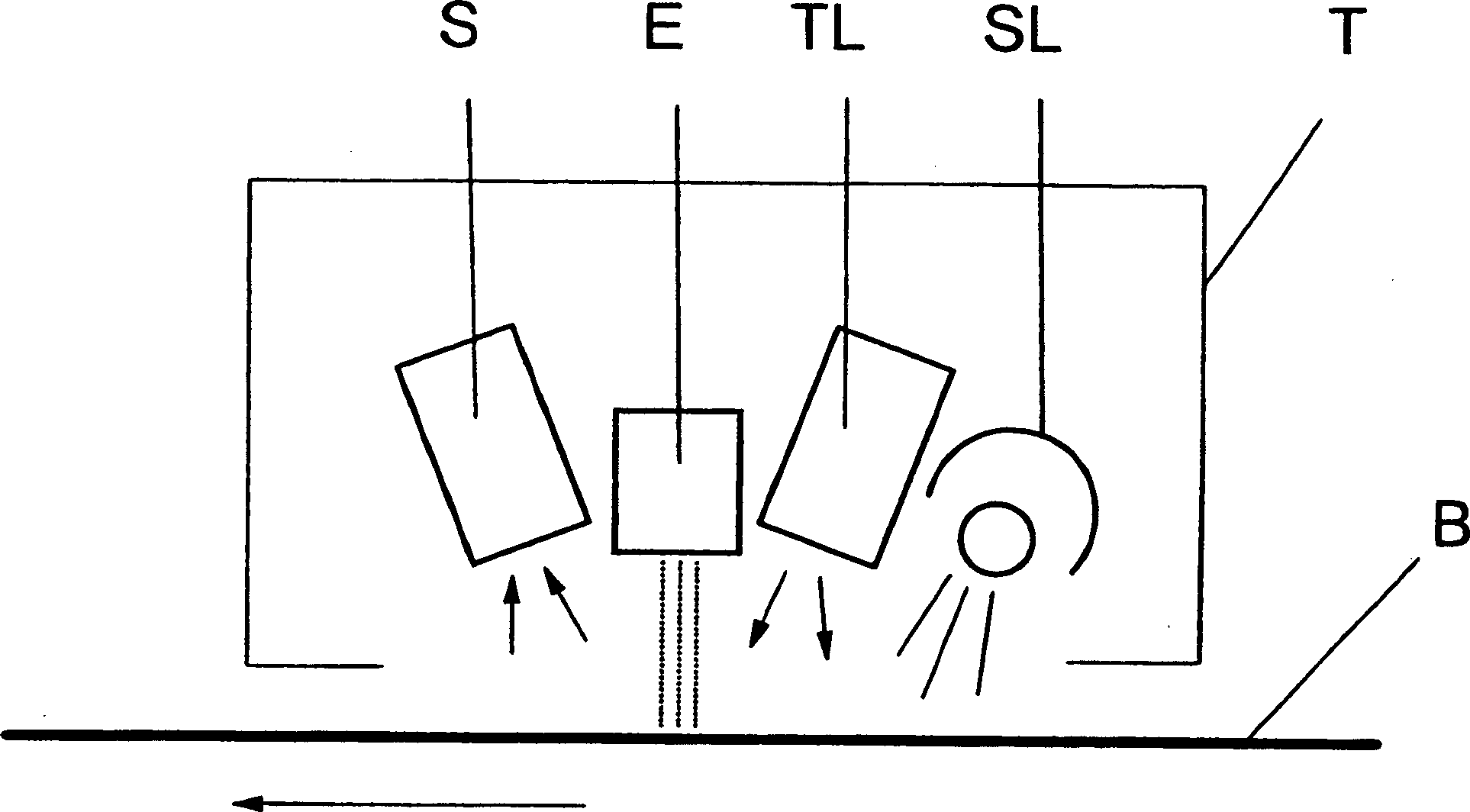

[0028] figure 1 The final printing unit of a sheet-fed offset printing press with impression cylinder 2 , blanket cylinder 3 and plate cylinder 4 is shown. Arranged upstream of the impression cylinder 2 is a transport cylinder 1 which transports the printed sheets transported from the preceding printing unit. The printed sheet conveyed by the conveying cylinder 1 is supported by the printed sheet guide 11 from both sides of the double printing surface. Behind the impression cylinder 2 of the final printing unit, an inking device and a chamber-shaped doctor blade 7 working together with the anilox ink roller 6 are arranged, and the inking device has an impression cylinder 2, a printing plate cylinder 5, a Inking roller 6. From the impression cylinder 2 of the final printing unit, the printed sheet is fed to the impression cylinder of the inking unit via the transport cylinder 1 and the associated guide 11 . The printed sheet on the impression cylinder 2 in the inking unit is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com