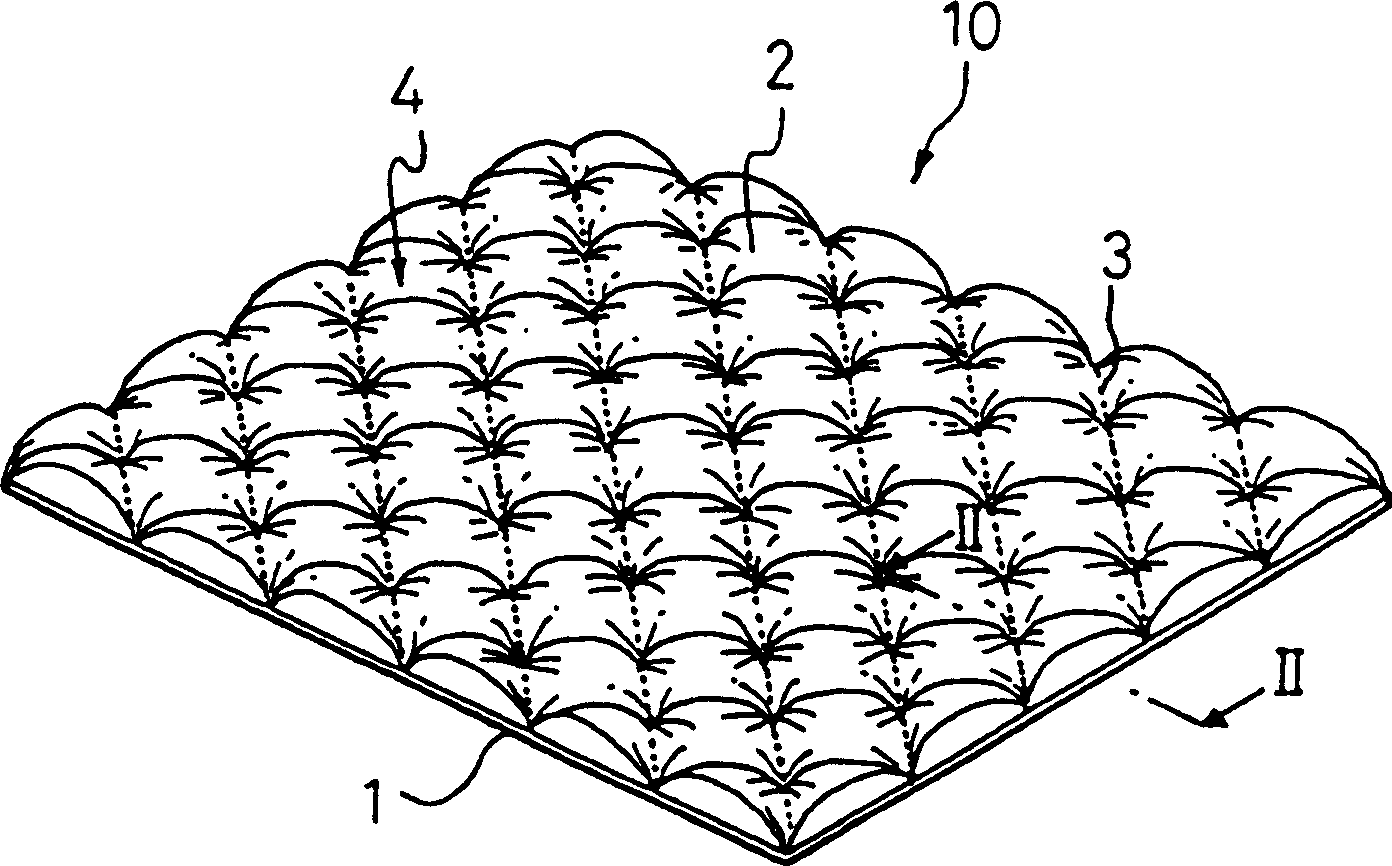

Bulk thin sheet material with 3-D embossment

一种膨松、薄片的技术,应用在织物、纺织、纺织品和造纸等方向,能够解决易起绒毛、凸起易陷缩等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

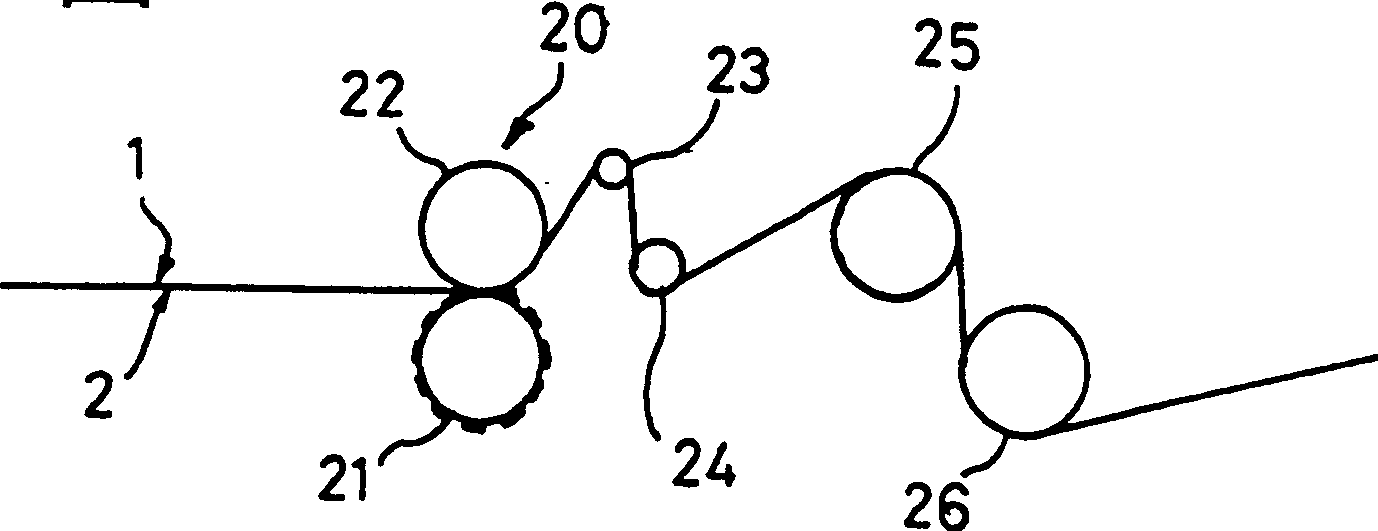

[0067] Embodiment 11) Preparation of the first fiber layer forming material

[0068] The self-curling fiber (it is a heat-shrinkable sheath-core composite fiber composed of a polypropylene (PP) core and an ethylene-propylene copolymer (EP) sleeve, with a core / sheath weight ratio of 5 / 5, has a fineness 2.2 dtex, fiber length 51 mm and shrinkage initiation temperature Ts of 90° C., (CPP, available from Daiwabo Co., Ltd.)) were carded with a roller carding machine to form a fiber having a basis weight of 12 g / m 2 fiber web. 2) Preparation of second fiber layer forming material

[0069] The thermally bondable sheath-core composite fiber (which consists of a polyethylene terephthalate (PET) core and a polyethylene fiber (PE) sheath with a core / sheath weight ratio of 5 / 5 and fineness 2.2dtex, fiber length 51mm (NBF-SH, can obtain from Daiwabo Co., Ltd.)) carding with roller carding machine, form and have basis weight 13g / m 2 fiber web. 3) Preparation of bulk...

Embodiment 2

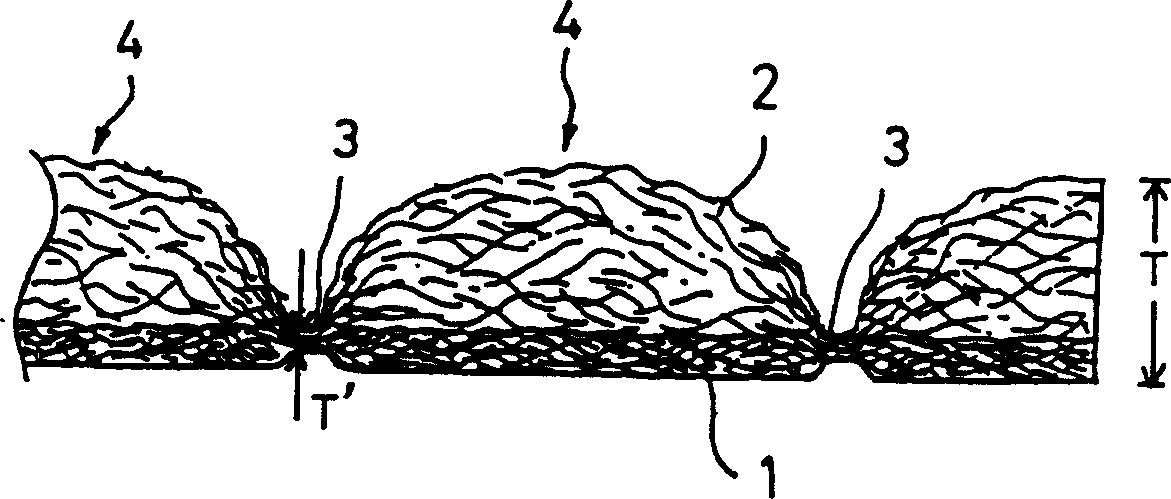

[0073] A bulky sheet material was prepared in the same manner as in Example 1, except that the set temperatures of the embossing rolls and smooth rolls were changed to the temperatures shown in Table 1 below. The resulting lofty sheet material has a large number of protrusions formed by the second fibrous layer which arches between connection points due to contraction of the first fiber layer, and connection points which form depressions.

Embodiment 3

[0075] The same method as in Example 1 was used to obtain a bulky sheet material, except that (i) the setting temperature of the embossing roller and smooth roll was changed to the temperature shown in Table 1 and (ii) the embossing roller was placed in the depression There is no insulation, but instead (iii) both webs are wrapped at a wrap angle of 60° on a smooth roll to apply tension on the CD. The resulting lofty sheet material has a large number of protrusions formed by the second fibrous layer which arches between connection points due to contraction of the first fiber layer, and connection points which form depressions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| apparent density | aaaaa | aaaaa |

| base weight | aaaaa | aaaaa |

| fineness modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com