Inner high-pressure formation process with low pressure source

A technology of internal high-pressure forming and low-pressure source, which is applied in the field of low-pressure source internal high-pressure forming, and can solve the problems of high-pressure source equipment being expensive, easily polluted, and affecting production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] The forming method of the present invention will be described in detail below by taking forming a hollow revolving member as an example.

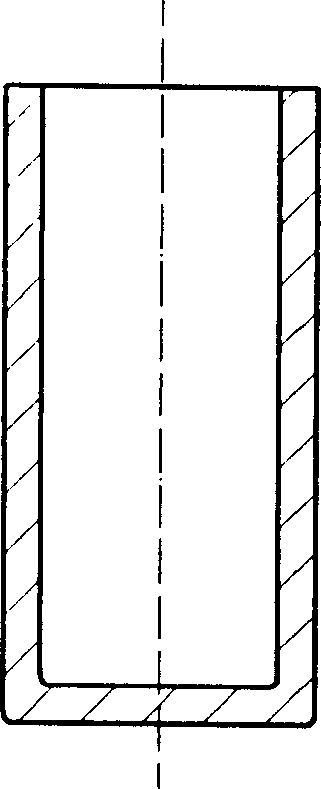

[0007] Such as figure 1 As shown, the workpiece blank of the embodiment is hollow. Barrel-shaped rotary body and shaped rotary body parts.

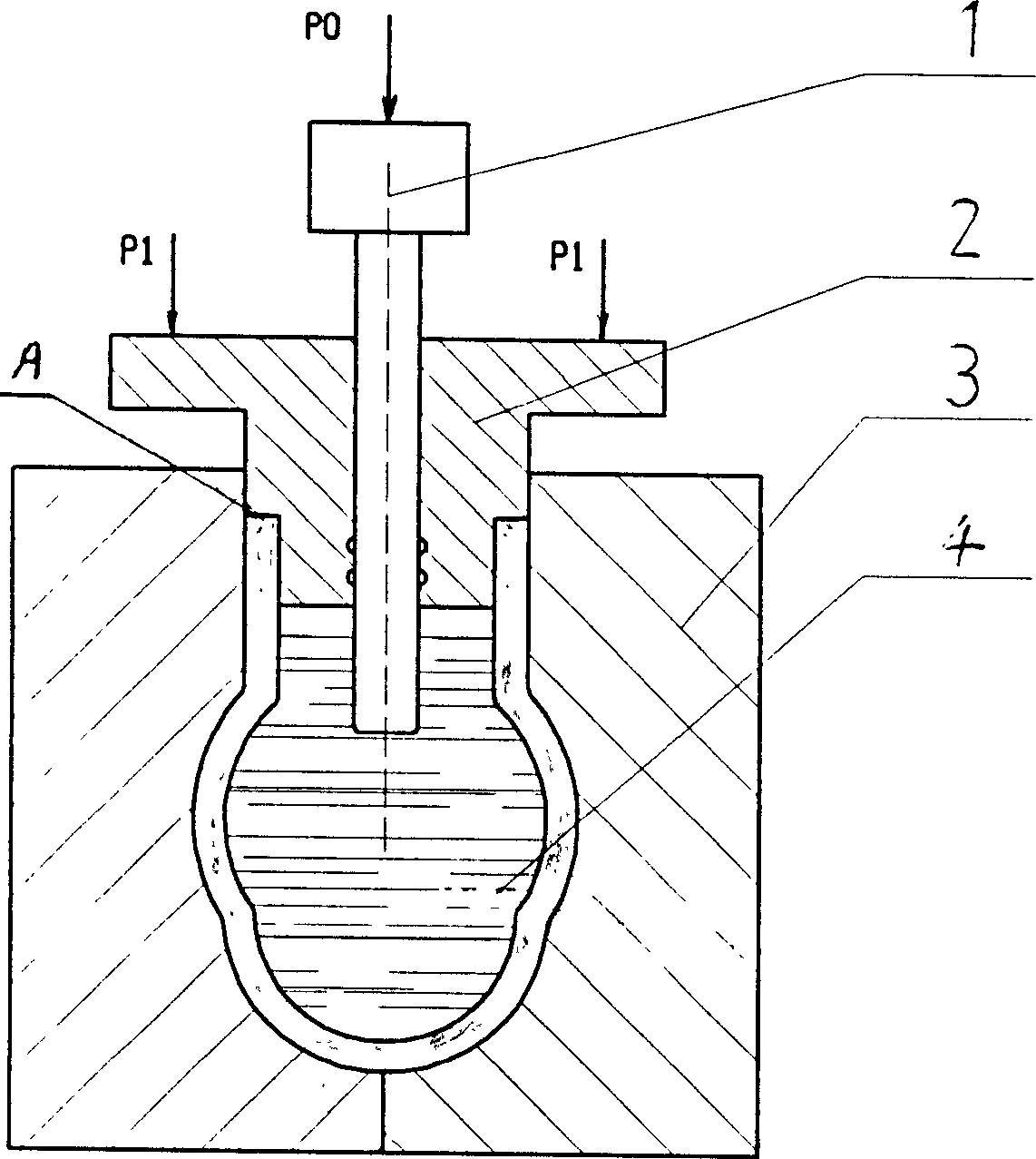

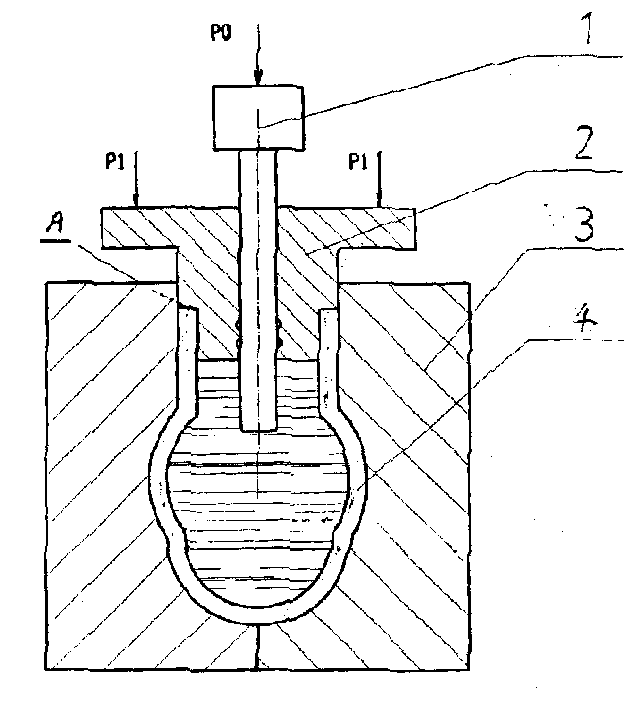

[0008] Such as figure 2 As shown, the whole mechanism is composed of booster piston 1, feeder 2, die 3, water 4 and so on. The barrel-shaped workpiece blank (see figure 1 ) into the separable die 3, add water 4 into the workpiece blank, there is a through hole in the center of the feeder 2, and a booster piston 1 is installed inside, the lower end enters the workpiece blank, the upper end is slippery with the die 3, and the middle The boss A is pressed against the end of the workpiece blank. Feeder 2 upper end pressure P 1 On the one hand, it is to increase the sealing performance, and on the other hand, it can also compensate for the metal required during the deformation process of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com