Reciprocating compressor

A reciprocating compressor technology, applied in the field of reciprocating compressors, can solve the problems of increased cost of high-priced magnet materials, reduced compressor efficiency, and enlarged compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

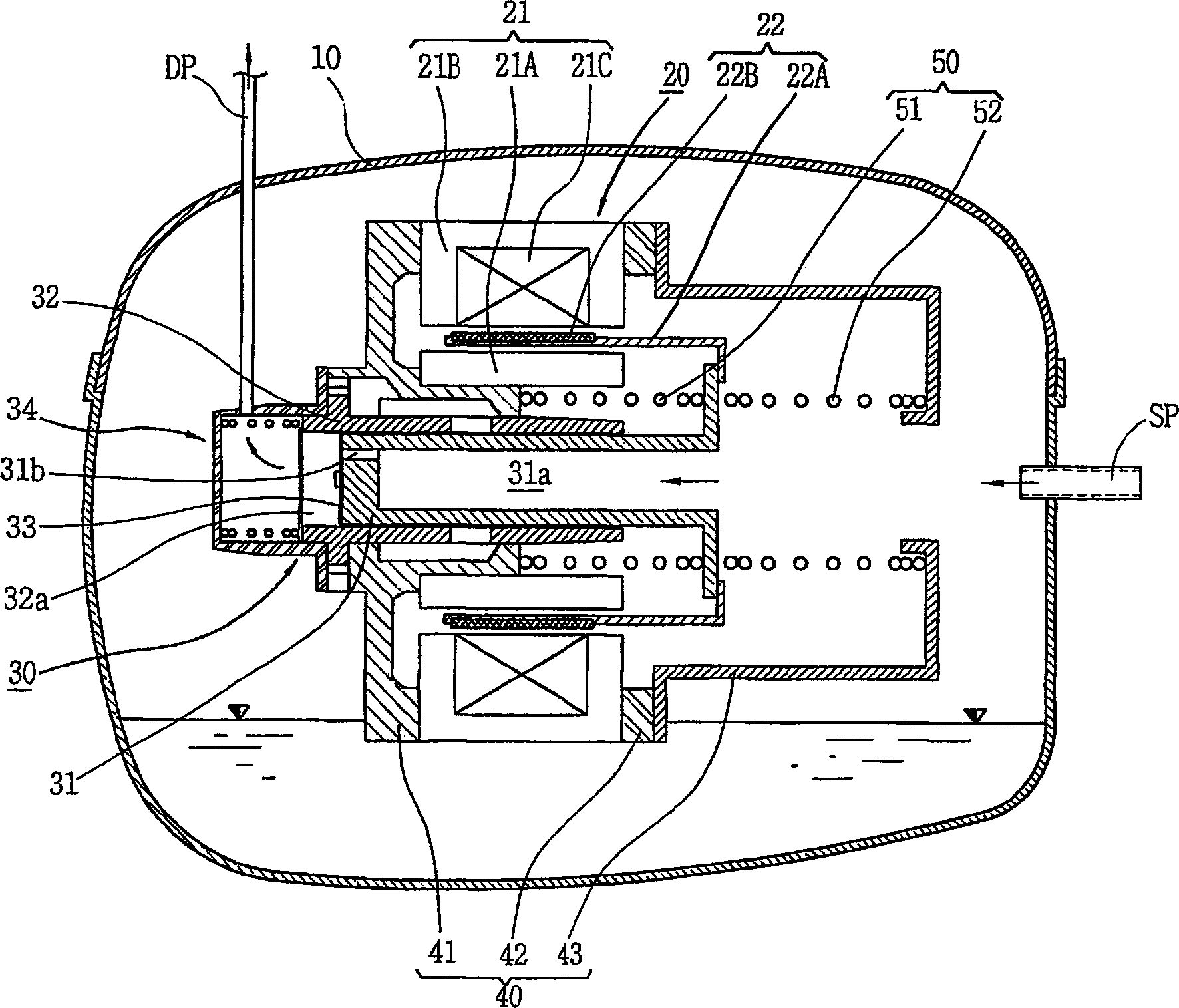

[0030] A reciprocating compressor according to a preferred embodiment of the present invention will now be described with reference to the accompanying drawings.

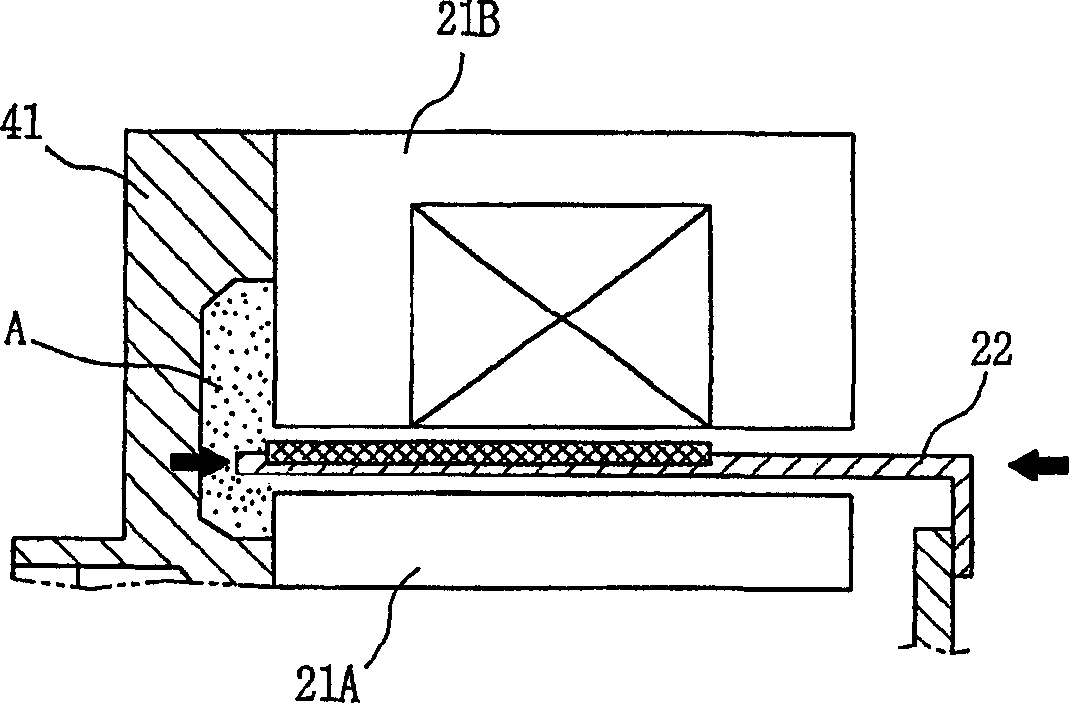

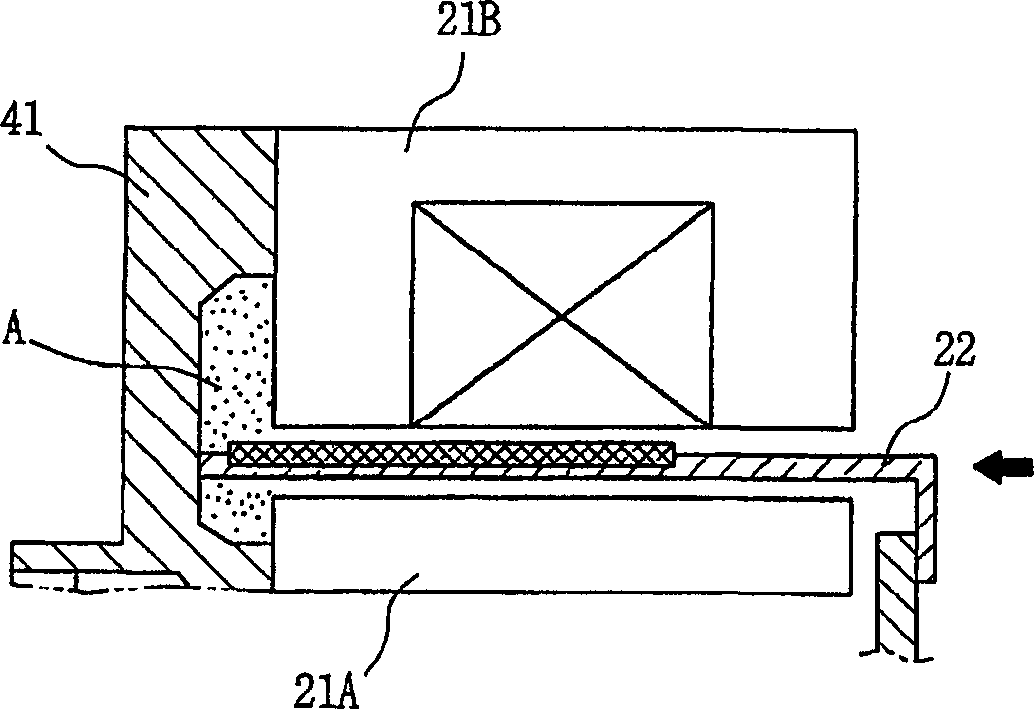

[0031] image 3 is a vertical sectional view of an example of a reciprocating compressor according to a preferred embodiment of the present invention, Figure 4 is a schematic sectional view of the main parts of the reciprocating compressor according to the preferred embodiment of the present invention, Figure 5A is a schematic sectional view of an operating state of the armature of the reciprocating compressor according to the preferred embodiment of the present invention, Figure 5B is a schematic sectional view of an operating state of the armature of the reciprocating compressor according to the preferred embodiment of the present invention.

[0032] As shown in the drawings, a reciprocating compressor of the present invention includes a closed shell 10 whose lower part is filled with lubricant and has a suct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com