Gas shock-wave generating device

A generating device and shock wave technology, applied in the direction of solid residue removal, combustion product treatment, combustion method, etc., can solve the problems of short time, difficult to achieve door opening effect, difficult to produce usable strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

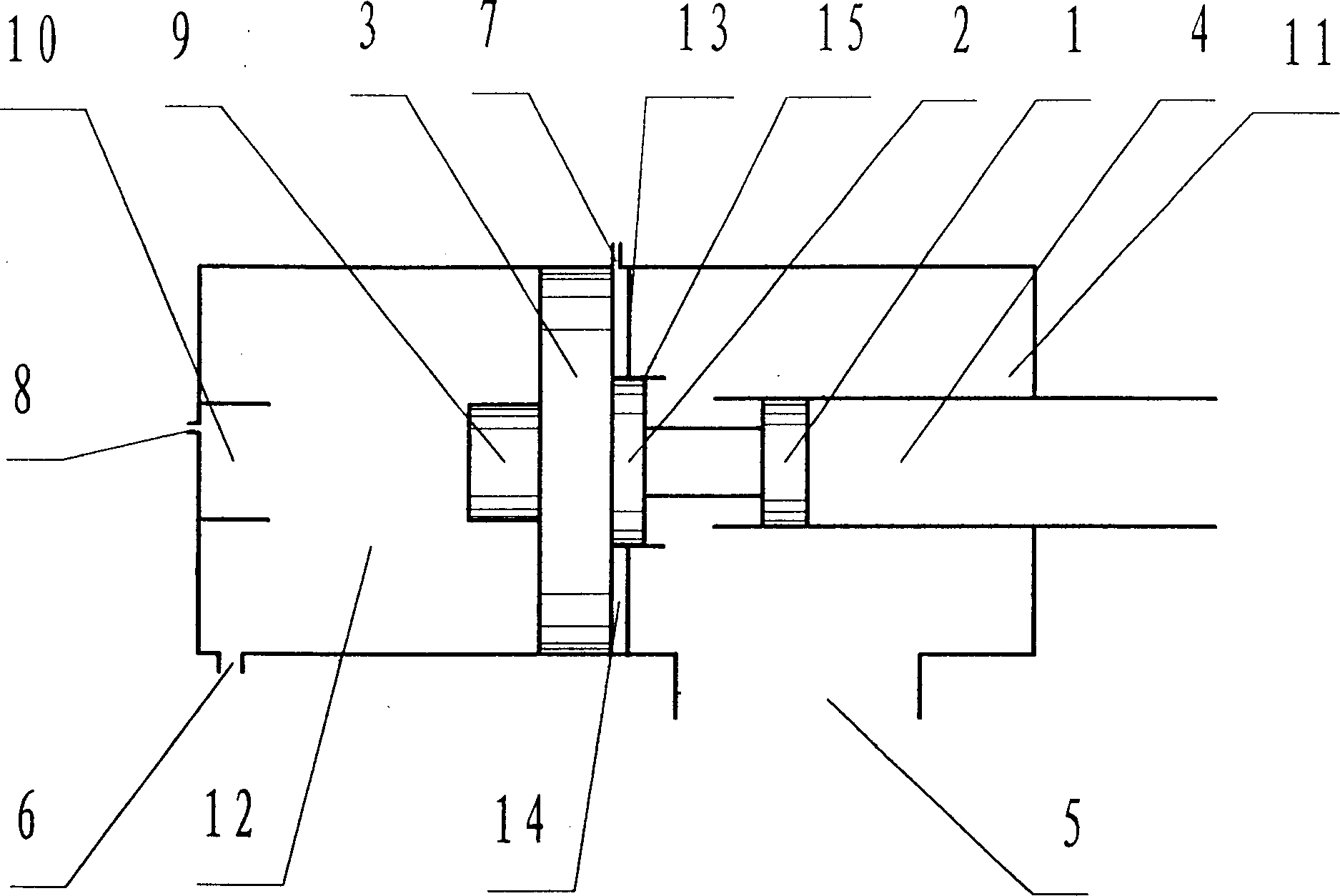

[0019] Example 1: figure 1 Among them, piston 1, piston 2, and piston 3 form a sealed piston group with different sealing cross-sectional areas, piston 1 separates the gas between the sealed energy storage chamber 11 and the shock tube 4, and piston 2 separates the sealed rear chamber 14 from the To seal the gas between the energy storage chambers 11, the sealing cross-sectional area of the piston 2 refers to the sealing cross-sectional area of the piston 2 to the side of the energy storage chamber 11, and the piston 3 separates the gas between the sealed front chamber 12 and the sealed rear chamber 14, and its Corresponding sealing section diameters are D 1 、D 2 、D 3 , the middle partition 13 and the piston 3 divide the device into three chambers: the sealed front chamber 12, the sealed rear chamber 14, and the sealed energy storage chamber 11, D 3 >D 2 ,D 3 -D 2 Take big, D 2 >D 1 ,D 2 -D 1 Take very small. figure 1 The working process shown in can be divided ...

Embodiment 2

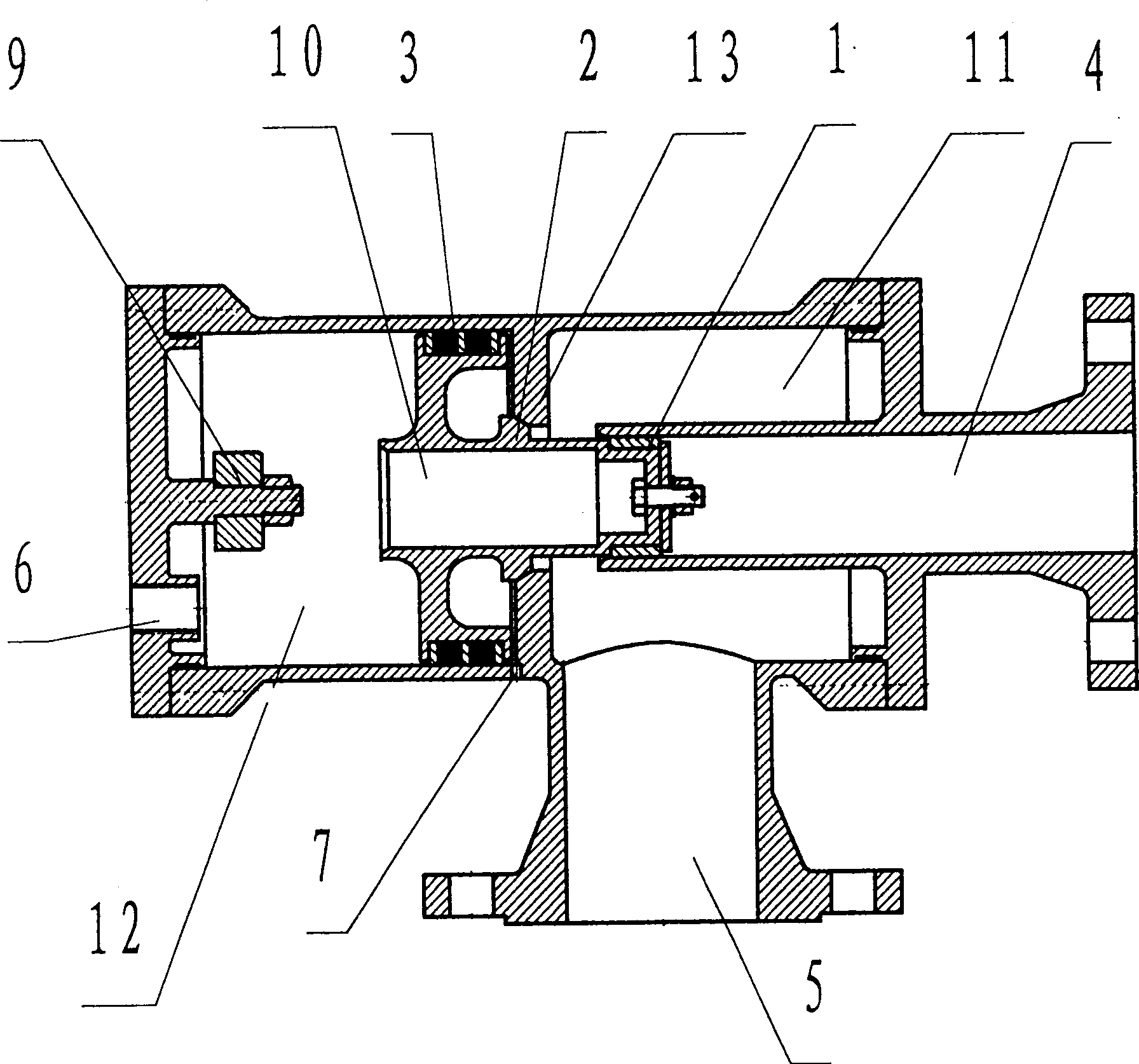

[0027] Example 2: figure 2 In the shown embodiment, the piston 1, the piston 2, the piston 3 and the buffer chamber 10 form a whole, there is no connecting member between the pistons, and the external gas storage tank is partially communicated with the sealed energy storage chamber 11 through the large-diameter air inlet 5, connect. When the piston group impacts at a high speed, after the piston 1 opens the door for a certain distance, the buffer plunger 9 enters the buffer chamber 10, and the buffer plunger 9 is provided with a buffer orifice with a small diameter. After the piston group is buffered for a certain distance, the impact stops.

Embodiment 3

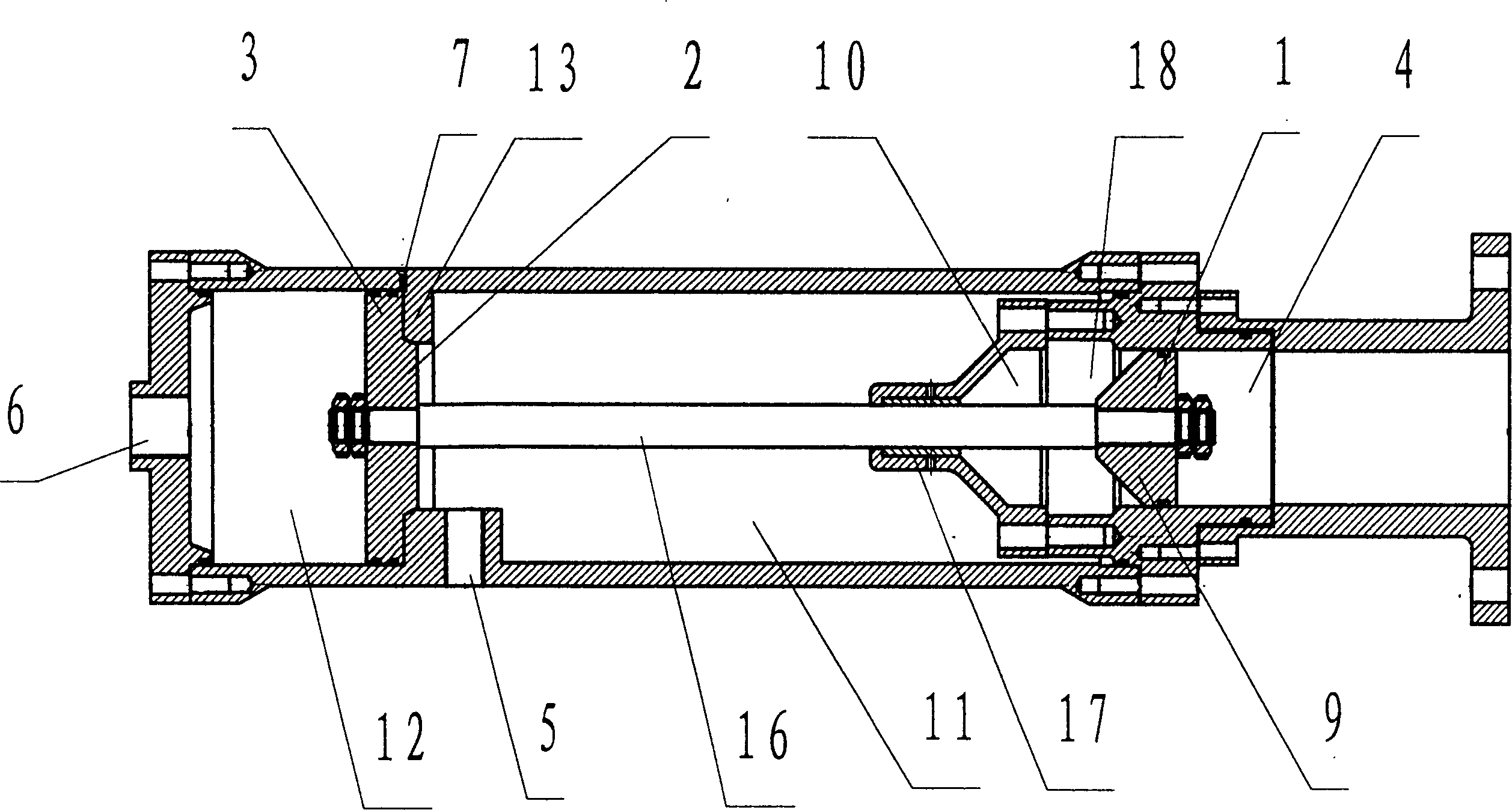

[0028] Example 3: image 3 In the shown embodiment, the gas storage tank and the energy storage chamber 11 are integrated, the piston 2, the piston 3 and the piston 1 are connected through the piston rod 16, and the buffer chamber 10 is placed in the sealed energy storage chamber 11 and connected to the piston rod shaft 17 Connected as a whole, the circumferential inlet slot 18 is between the buffer chamber 10 and the shock tube 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com