Method of recovering oxygen, nitrogen and air exhausted from air separator

A technology of air separation unit and nitrogen, which is applied in the fields of air liquefaction recovery, vented oxygen and nitrogen, which can solve the problems of large investment and achieve the effects of less investment, improved utilization rate and strong reserve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

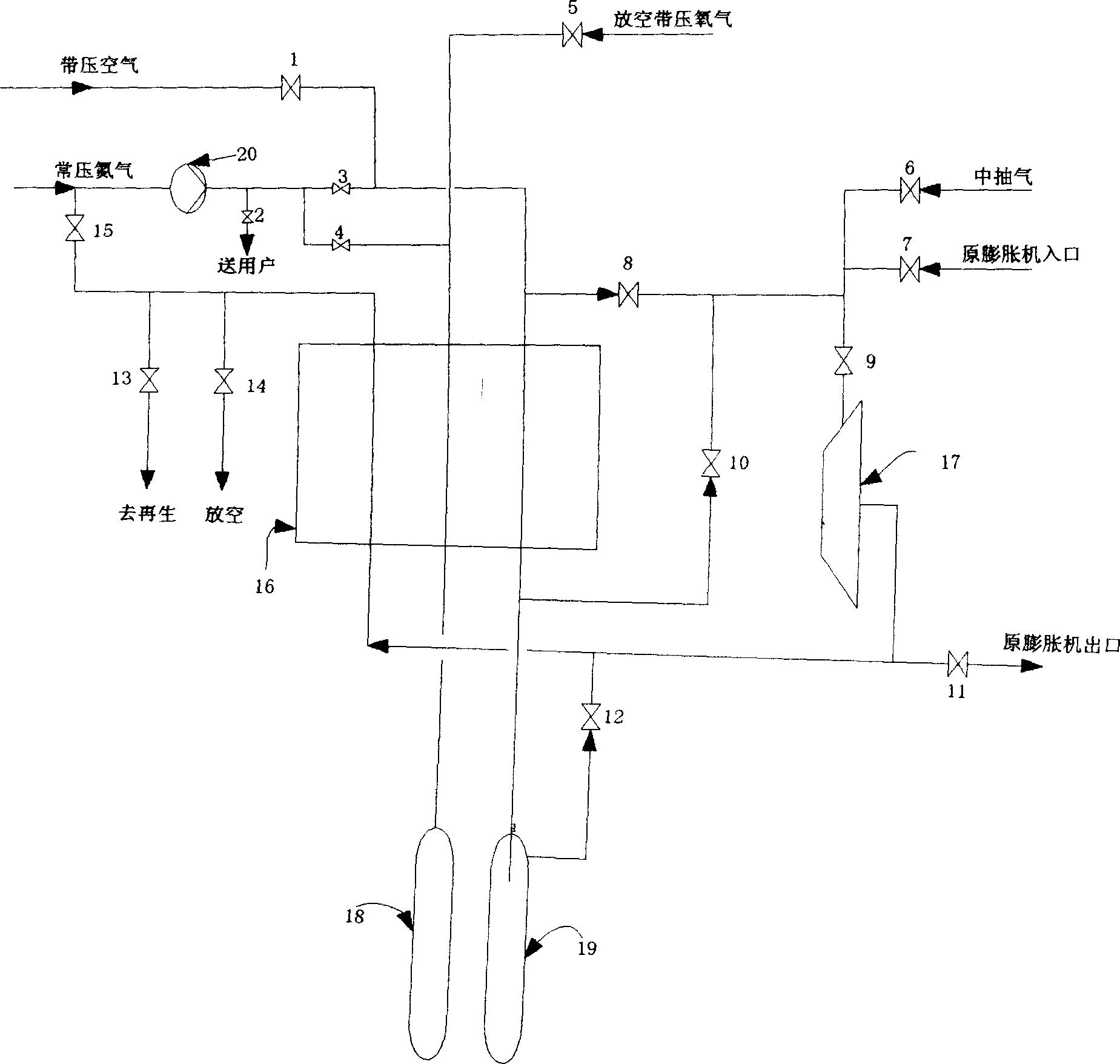

[0020] The present invention will be further described below in conjunction with the accompanying drawings, but the scope of the present invention is not limited.

[0021] When using the vented pressurized air as the cooling medium: in figure 1 In the process, the part of the air with pressure obtained after compression and purification is sent to the heat exchanger 16 through the valve 1, and the cold air flow is obtained after cooling through the heat exchanger 16. The temperature is -156 ° C ~ -168 ° C, and at least Part of the cold air flows through the valve 10 and part of the pressurized air (temperature is 10-20°C) that does not pass through the heat exchanger passes through the valve 8 and then merges into the inlet of the spare expander 17 of the air separation unit, and is adjusted to pass through the heat exchanger. The air volume of 16 and valve 8 and the air volume passing through valve 10 make the temperature of the combined air meet the inlet temperature of expa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com