Method of embedding glass fiber reinforced plastics or gypsum sculptural pattern onto wooden line with decorative line

A decorative line and fiberglass technology, applied in the field of building materials, can solve the problems of rising manufacturing costs, restricting the growth of economic benefits, and high-quality workers, and achieve great economic and social benefits, easy promotion and popularization, and beautify the living environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

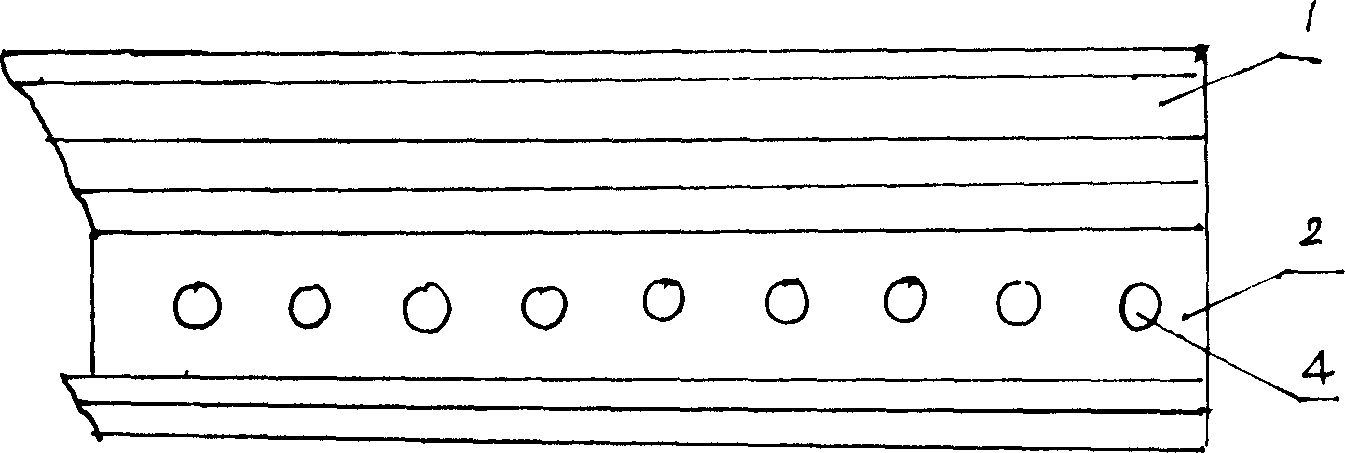

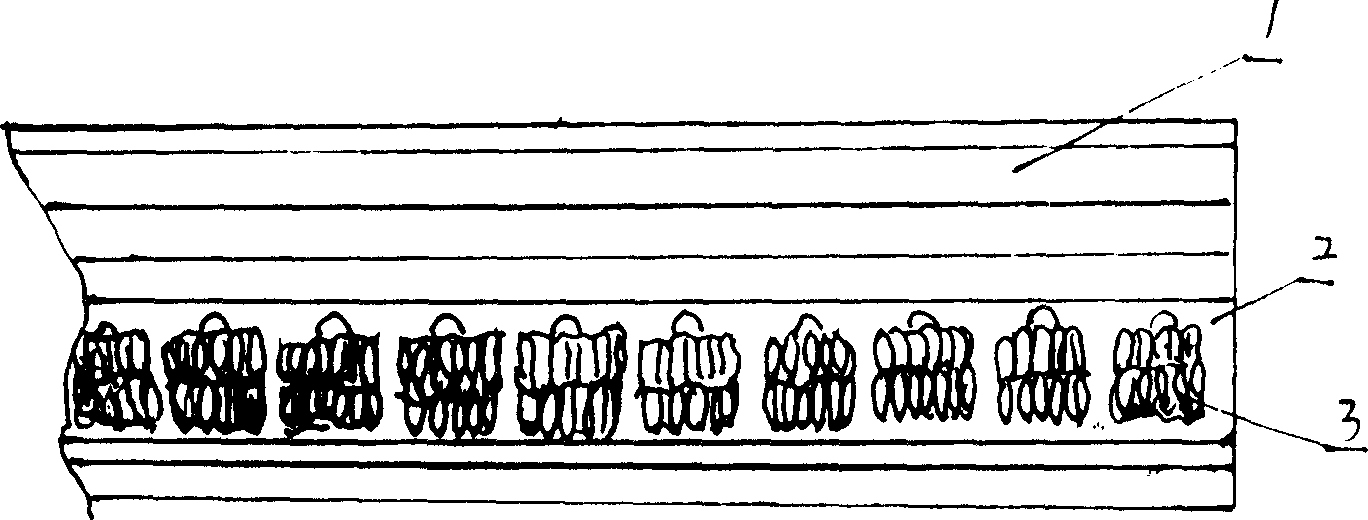

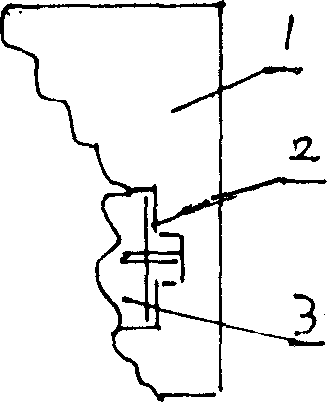

[0015] according to figure 1 , figure 2 , image 3 , as shown:

[0016] (1) at first process the striped board 1 with decorative straight lines and square grooves 2 with woodworking machinery;

[0017] (2) According to the needs of decoration and aesthetics, design pattern patterns, design and manufacture molds based on the designed pattern patterns, and use the molds to process the glass fiber reinforced plastic sculpture patterns 3 of the designed pattern patterns;

[0018] (3) Process the hole 4 inlaid with glass fiber reinforced plastic sculpture flowers in the square groove 2 of the line plate 1 with decorative straight lines;

[0019] (4) FRP sculpture pattern 2 is embedded in the hole 4 of the square groove 2 of line plate 1, firmly with glass glue, then has the decorative line of FRP relief pattern to make.

Embodiment 2

[0021] according to Figure 7 , Figure 8 , Figure 9 As shown, the production method is the same as (1) and (2) of embodiment 1, (3) does not need to process holes, and (4) is to glue the glass fiber reinforced plastic sculpture pattern 3 to the square groove of the line plate 1 with glass glue 2 within.

Embodiment 3

[0023] according to Figure 4 , Figure 5 , Figure 6 As shown, the manufacturing method is the same as (1) (2) of Embodiment 1, (3) bar does not need to process the hole 4, (4) bar is that the glass fiber reinforced plastic sculpture pattern 3 is nailed to the square groove 2 of the strip plate 1 with screws Inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com