Pinch roll unit for underground winding machine and with adjustable offset distance and its adjusting method

A technology of offset distance and pinch roll, which is applied in the field of pinch roll device of downcoiler, which can solve the problems of affecting the quality of strip steel head, aggravating adverse consequences, shortening equipment life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

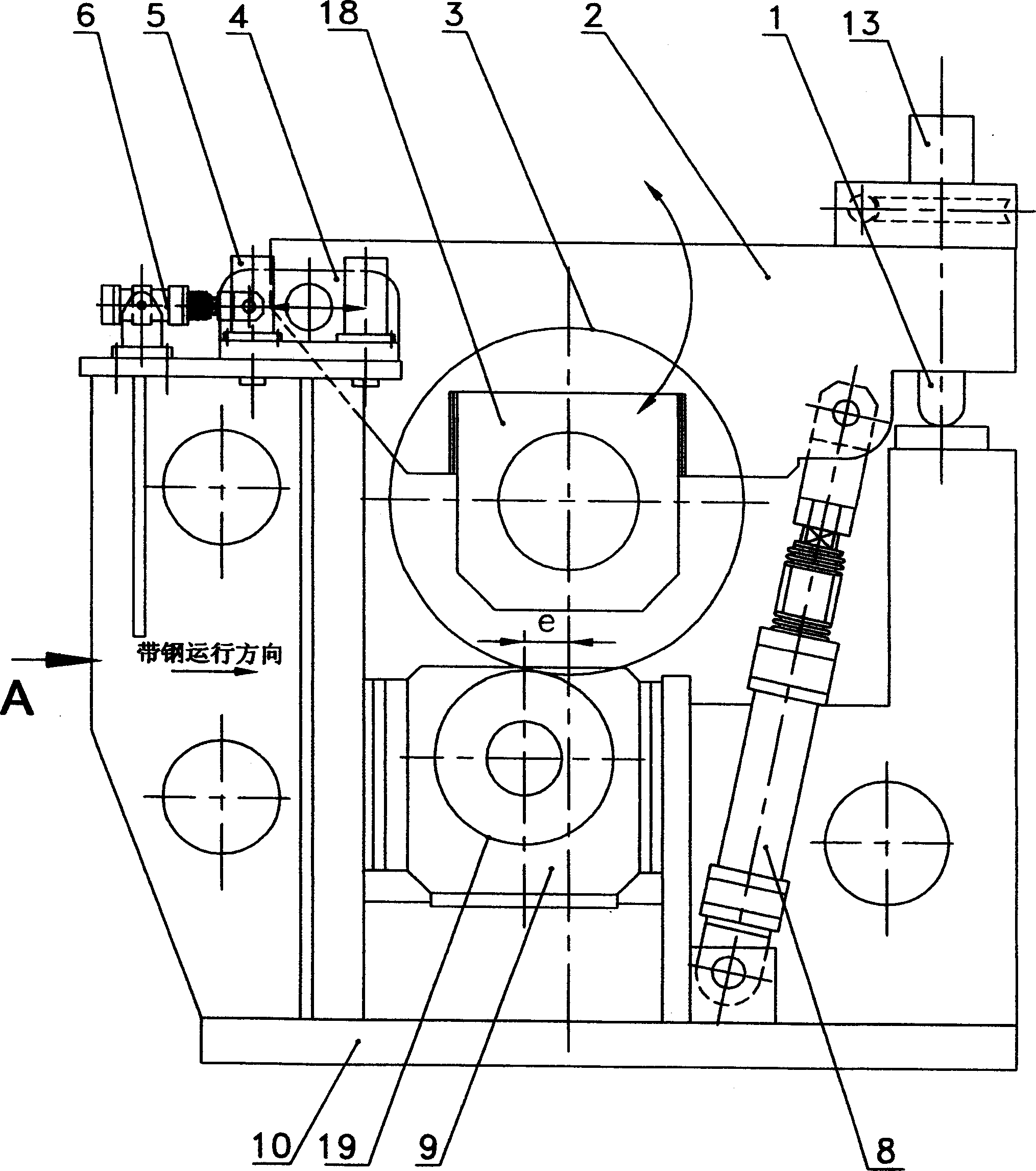

[0061] see figure 1 , figure 2 : The structure shown in the figure is the swing type pinch roller device of the present invention. The device is bilaterally symmetrical, so only one side needs to be described. However, it should be pointed out that both sides of the following operations and action processes are carried out synchronously.

[0062] The swing-type pinch roller device: includes frame 10, lower pinch roller 19 and its bearing seat 9, upper pinch roller 3 and its supporting mechanism composed of successively connected bearing seat 18, swing frame 2 and support 4 , the roll gap adjustment hydraulic cylinder 8, the roll gap locking mechanism composed of the motor 12, the connecting shaft 11, the worm gear reducer 13, and the screw rod 1, and the biasing mechanism composed of an adjusting hydraulic cylinder 6 and four locking hydraulic cylinders 5 Shift adjustment mechanism.

[0063] One end of the swing frame 2 is connected with the frame 10 through the support 4...

Embodiment 2

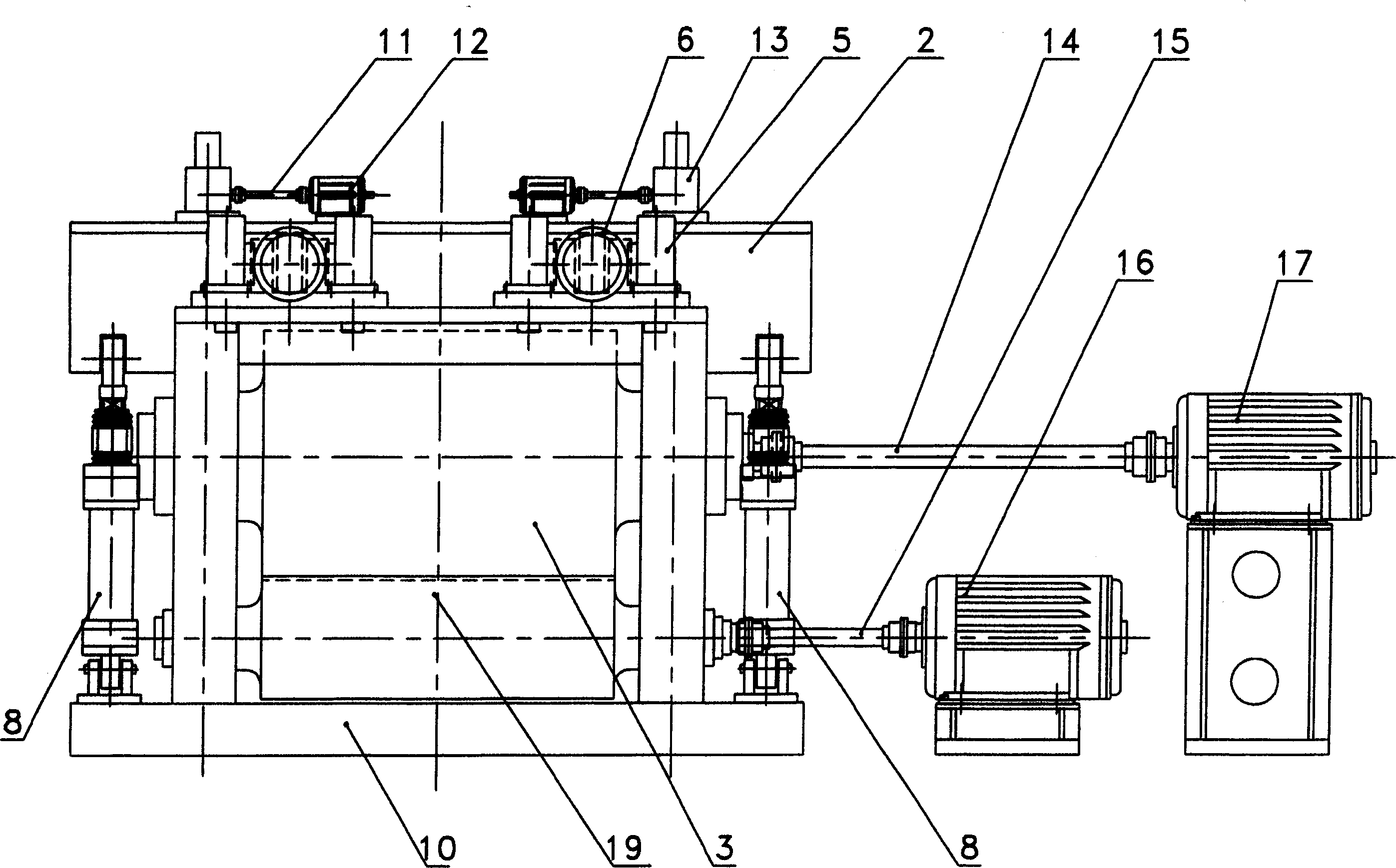

[0066] see image 3 , Figure 4 : the structure shown in the figure is the direct-acting pinch roller device (I) of the present invention. The device is bilaterally symmetrical, so only one side needs to be described. However, it should be pointed out that both sides of the following operations and action processes are carried out synchronously.

[0067] This direct-acting pinch roller device (I): includes frame 1 fixed on the rail seat 4, upper pinch roller device 2, by worm gear reducer 8, pressing screw rod 9, connecting shaft 11, motor 12 The upper pinch roller pressing mechanism constituted, the upper pinch roller balance mechanism and the positioning plate 3 composed of the balance hydraulic cylinder 7 and the balance beam 10, these mechanisms cooperate to adjust the size of the roll gap, and the upper and lower pinch rollers are respectively controlled by Its motor (16,15) is driven through connecting shaft (14,13), and this is that prior art is not described in deta...

Embodiment 3

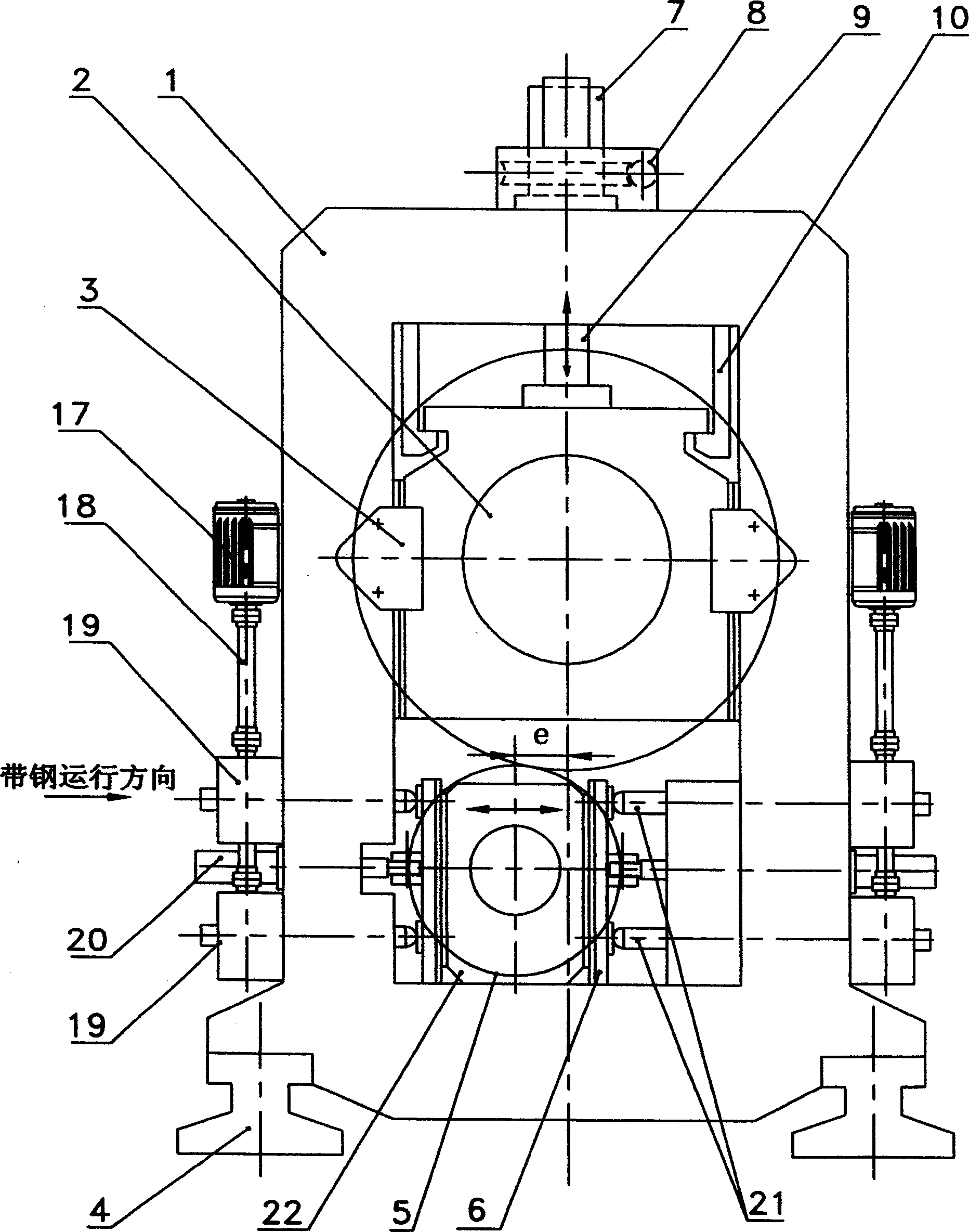

[0071] see Figure 5 , Fig. 6: The structure shown in the figure is the direct-acting pinch roller device (II) of the present invention. It differs from Embodiment 2 in that the adjustment mechanism on both sides of the bearing housing 22 has two hydraulic cylinders 20 and a screw jack 21 in each group, the screw jack 21 is mainly used for adjustment, and the hydraulic cylinder 20 is mainly used for locking and balancing.

[0072] When the value of offset e needs to be adjusted, according to whether the value of offset e needs to be adjusted up or down, the direction of movement is determined, and at the same time, the motors 17 of the screw jacks 21 on both sides are started, and the two screw jacks 21 are driven through the connecting shaft 18 and the worm wheel 19 The synchronous action overcomes the damping of the hydraulic cylinders 20 on both sides, so that the bearing seat 22 moves on the frame 1 until the value of the offset distance e meets the requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com