On-line mixing gas-supply equipment for magnesium alloy smelting protection

A magnesium alloy and equipment technology, which is applied in the field of protective gas online mixing equipment, can solve the problems of deteriorating working environment, flux slag inclusion, damage to equipment, etc., and achieve the effects of safety, reliability, automation, simple operation, and stable output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

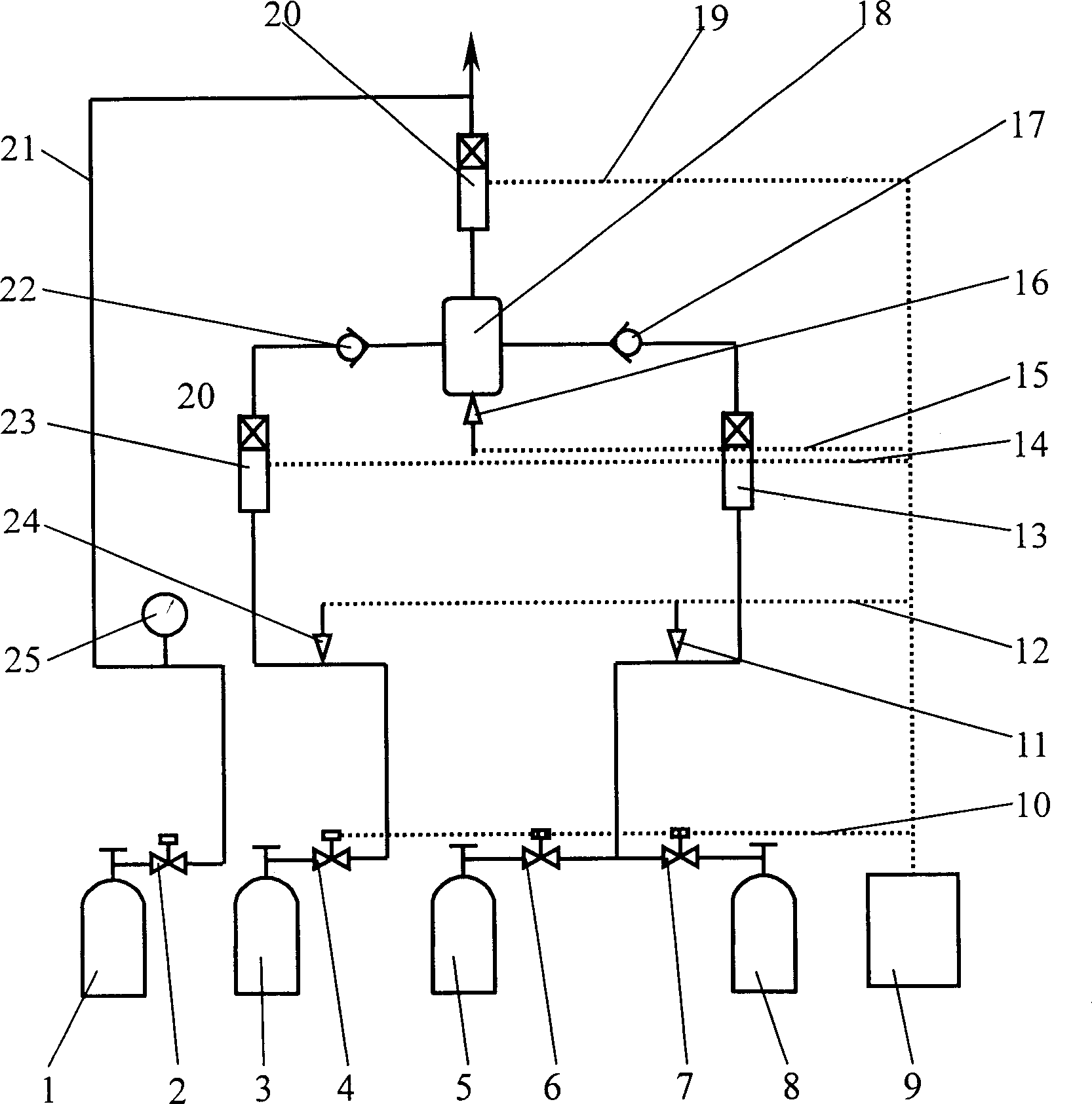

[0016] Further illustrate concrete structure and working process of the present utility model below in conjunction with accompanying drawing.

[0017] figure 1 It is a schematic structural diagram of an embodiment of an online mixed gas supply device for magnesium alloy smelting protection provided by the utility model. The online mixed gas supply equipment for magnesium alloy smelting protection mainly includes two parts: the standby mixed gas circuit and the mixed gas circuit; the standby mixed gas circuit is mainly composed of 15Mpa (N 2 -0.18wt% SF 6 ) mixed gas source 1, manual pressure reducing valve 2, visual pressure gauge or visual flow meter 25 and corresponding pipelines; There is always enough protective gas in the crucible to ensure that the system is sufficiently safe. The mixed gas path mainly includes nitrogen gas supply path, SF 6 The gas supply gas circuit is composed of a mixing tank 18 connected to the two gas circuits and an output gas pipeline; the ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com