Method for grinding metallic workpieces containing, in particular nickel

A metal workpiece and grinding technology, which is applied in the field of grinding, especially nickel-containing metal workpieces, to achieve the effect of improving the grinding results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

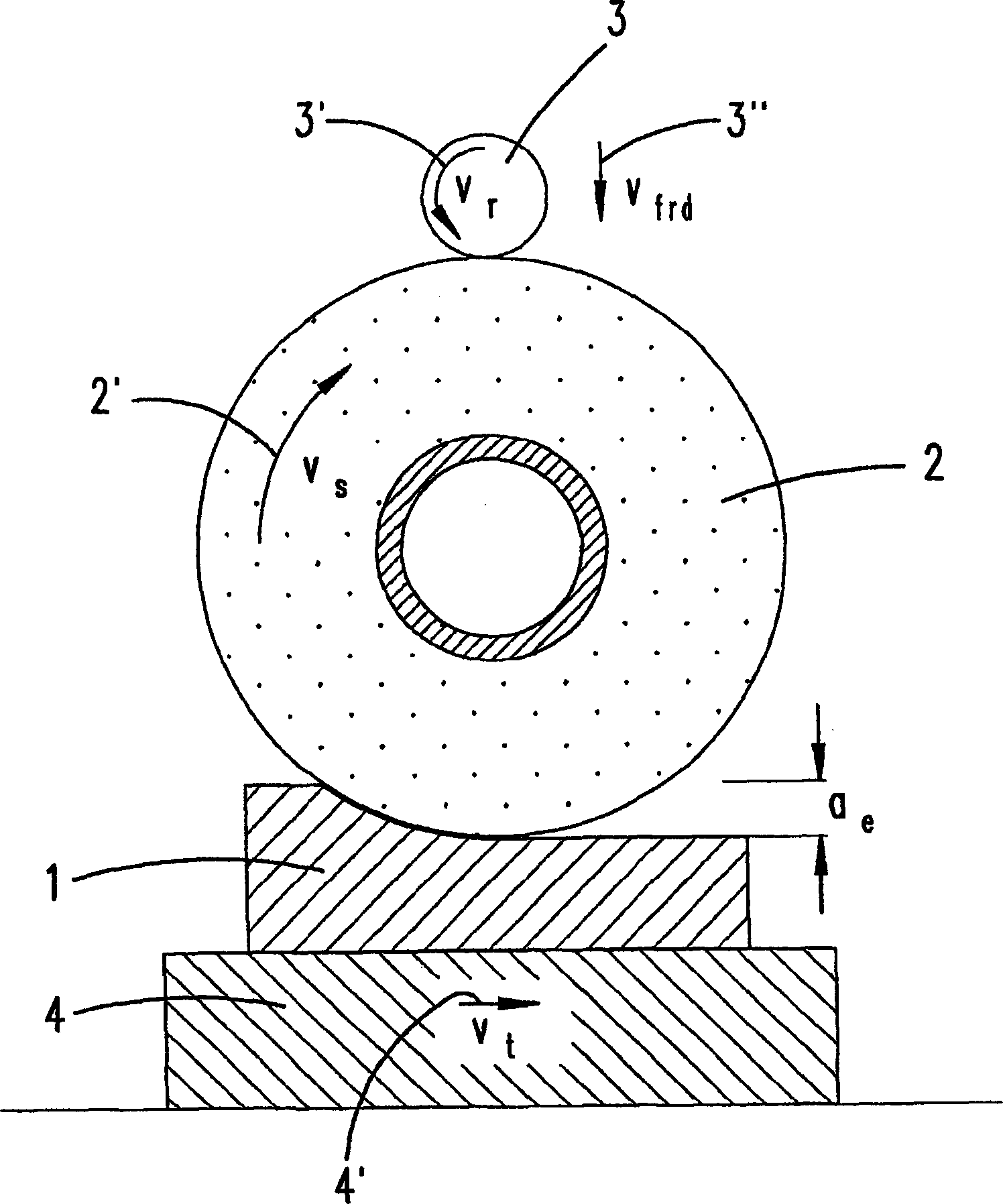

[0009] The device for grinding a workpiece 1 comprises a grinding wheel 2 which is continuously driven in rotation and is operated at a rotational speed at which the grinding wheel acts on the workpiece 1 at a grinding speed vs. The direction of rotation is indicated by arrow 2'.

[0010] The grinding wheel 2 is continuously corrected by the correcting wheel 3, which moves in the same direction 3' and can be moved in the direction of the arrow 3''. The speed of the dressing wheel is about 80% of the speed of the grinding wheel. In order to achieve the purpose of grinding, the circumferential surface of the grinding wheel 2 is e Cutting into a workpiece 1, the workpiece 1 is placed on a movable table 4, which moves at a speed vt in the direction indicated by the arrow 4'.

[0011] Grinding wheels consist of porous materials. 25% of the volume of the grinding wheel is formed by abrasive grains, 15% is formed by binder, and 50% of the volume is air. This is a porous grinding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com