Fluid coating method and device thereof

A coating method and a coating device technology, which can be applied to a device for coating a liquid on a surface, a spray device, a spray device, etc., and can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

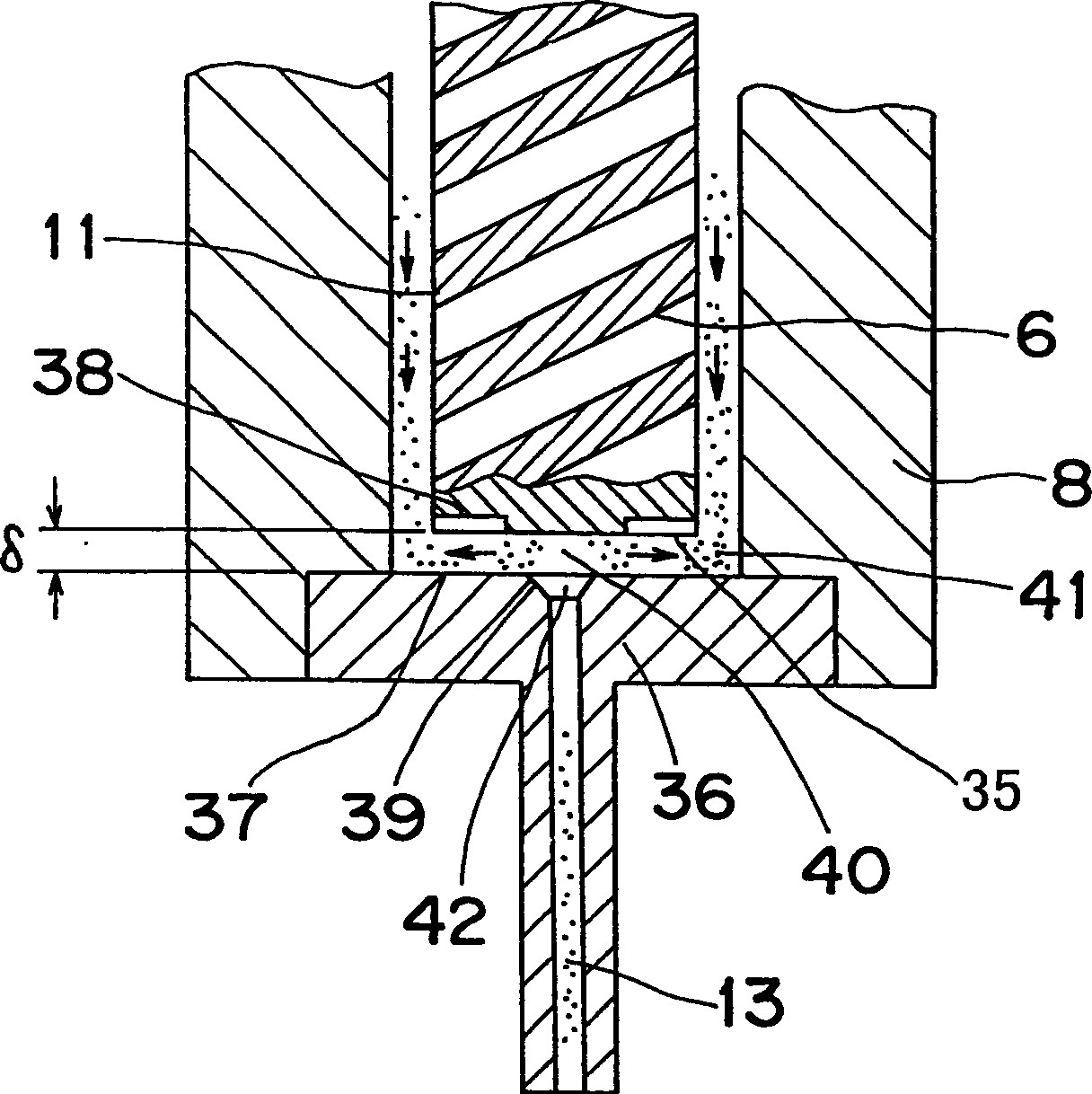

[0056] Before continuing the description of the present invention, the same reference numerals are given to the same parts in the drawings.

[0057] The embodiments of the present invention will be described in detail below based on the drawings.

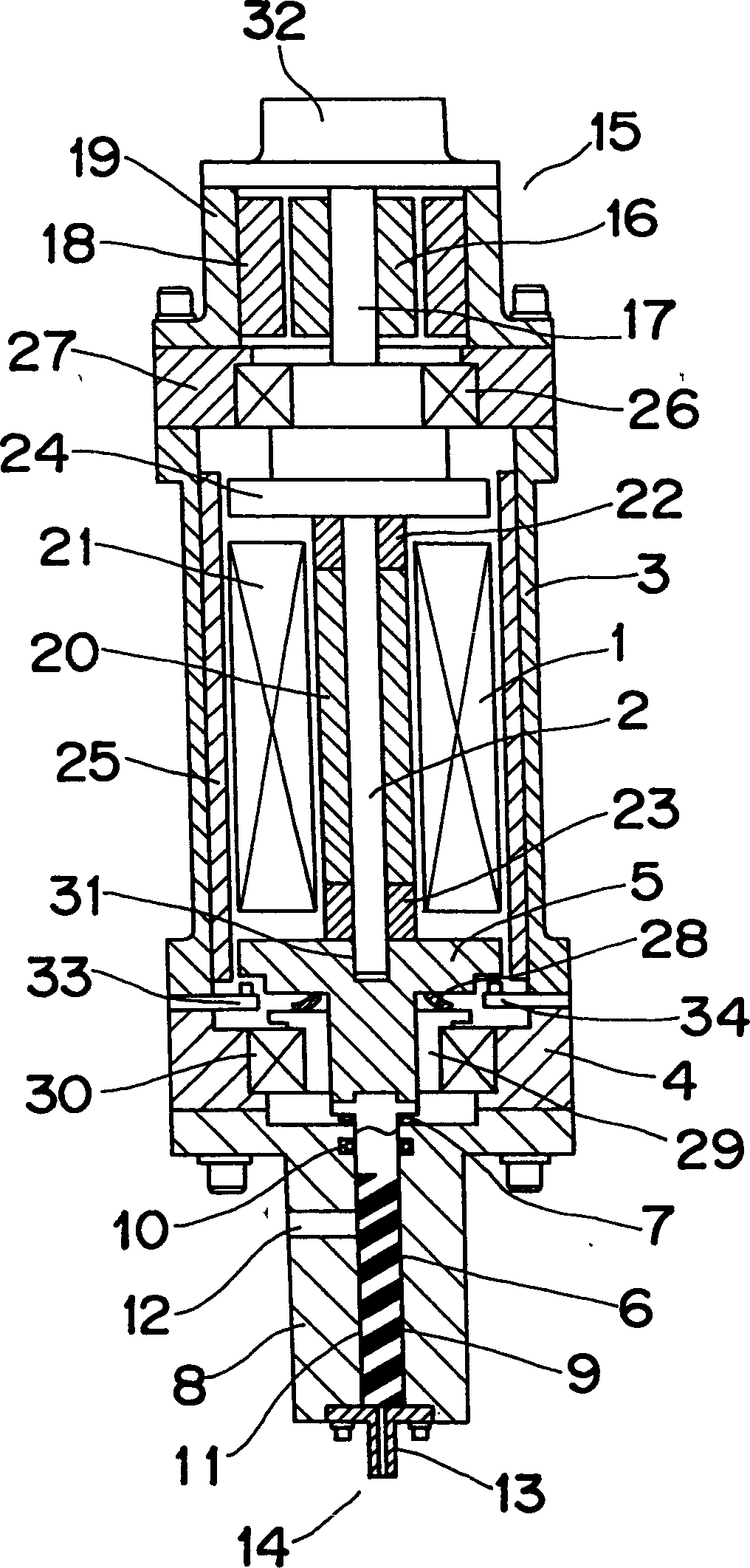

[0058] The following is about the first embodiment of a dispenser for surface mounting suitable for electronic components, using figure 1 The fluid application device of the fluid application method of the present invention will be described.

[0059] 1 is the first transmission device. In the first embodiment, in order to supply high-viscosity fluid with a small amount and high precision at high speed and intermittently, it is used to obtain high positioning accuracy and high responsiveness, and at the same time A giant magnetostrictive element with a large generated load can be obtained.

[0060] 2 is the central axis driven by the first transmission device 1. The first transmission device is installed in the sleeve 3. The front main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com