Apparatus for making high dust-containing material bag get off and recovering bag

A technology for bag recycling and materials, which is applied in the field of clean bag removal and bag recycling devices for materials with fungal spores, and can solve the problems of dust flying during bag removal operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

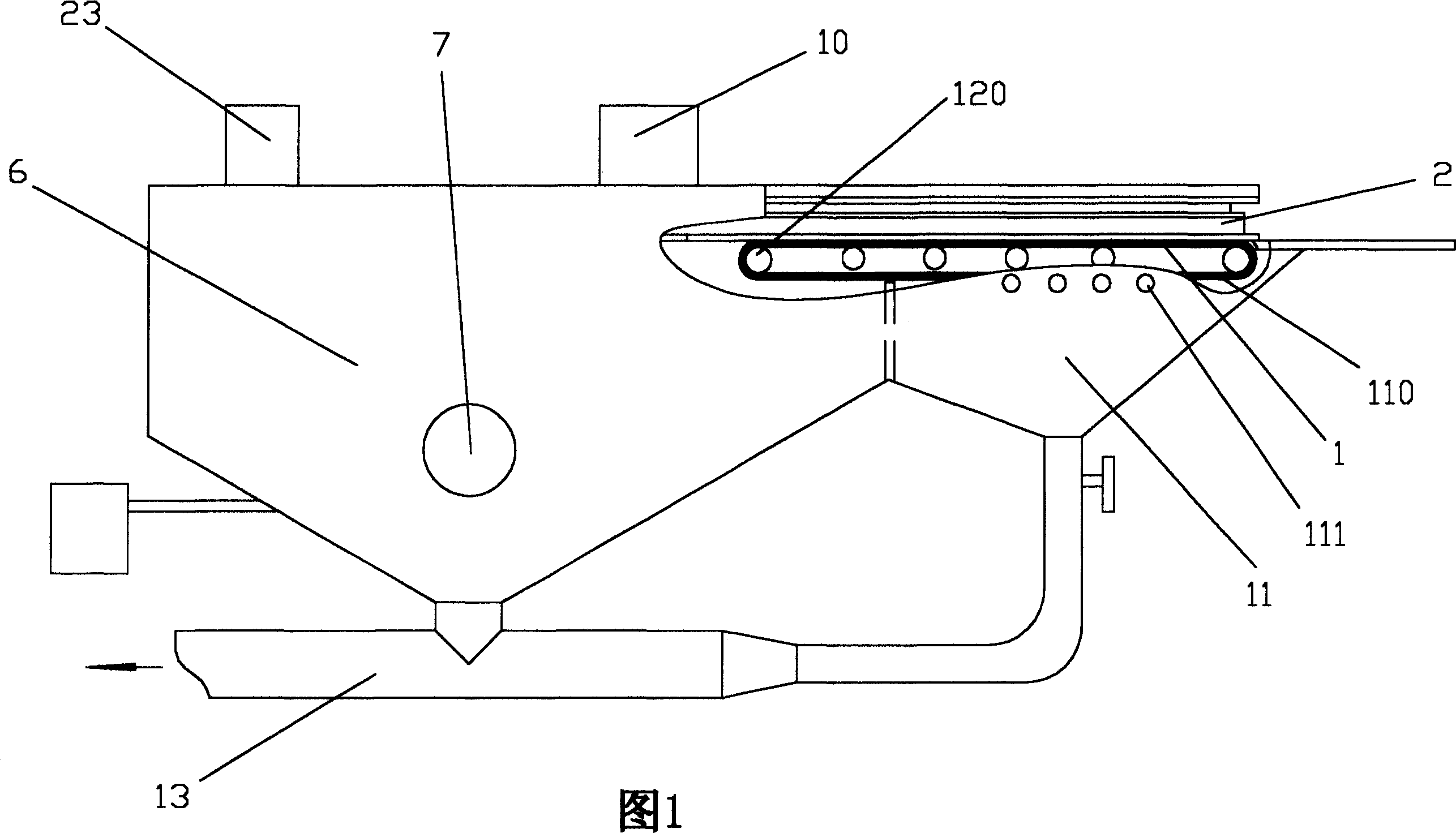

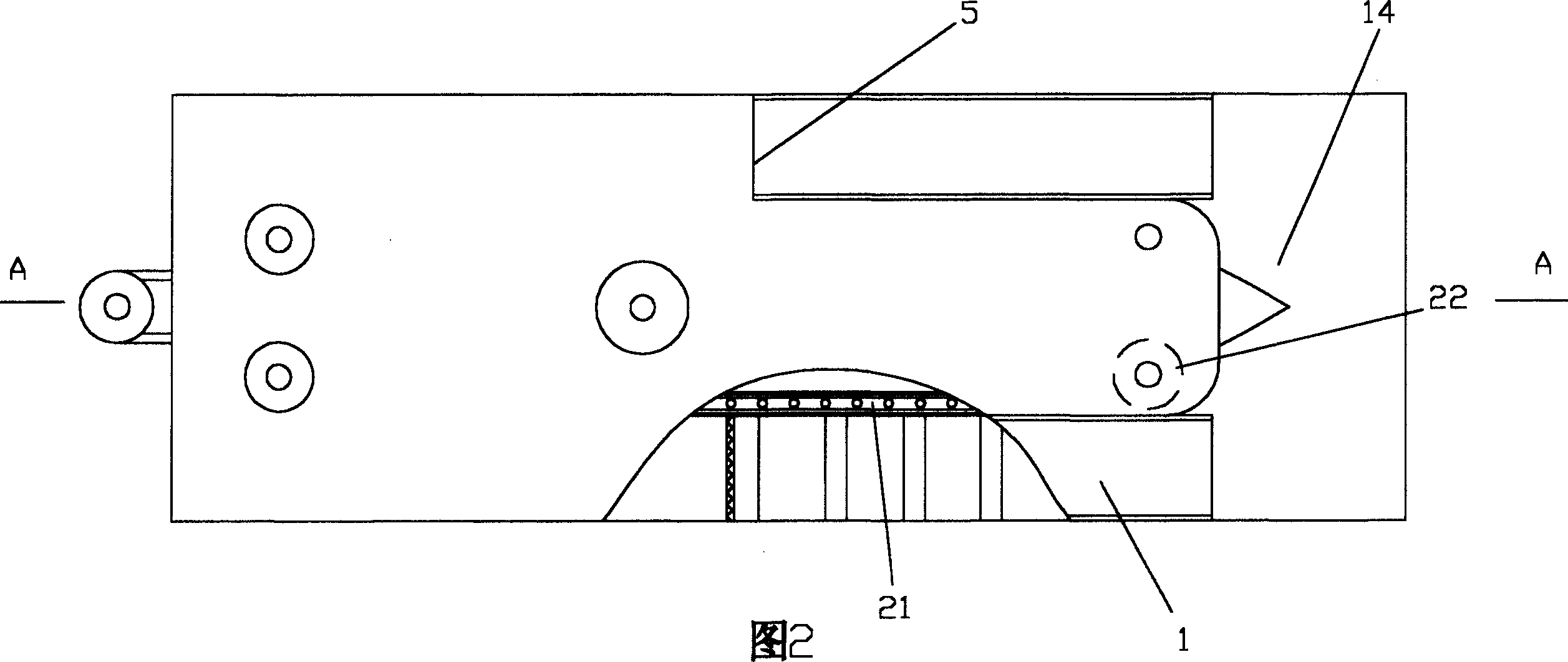

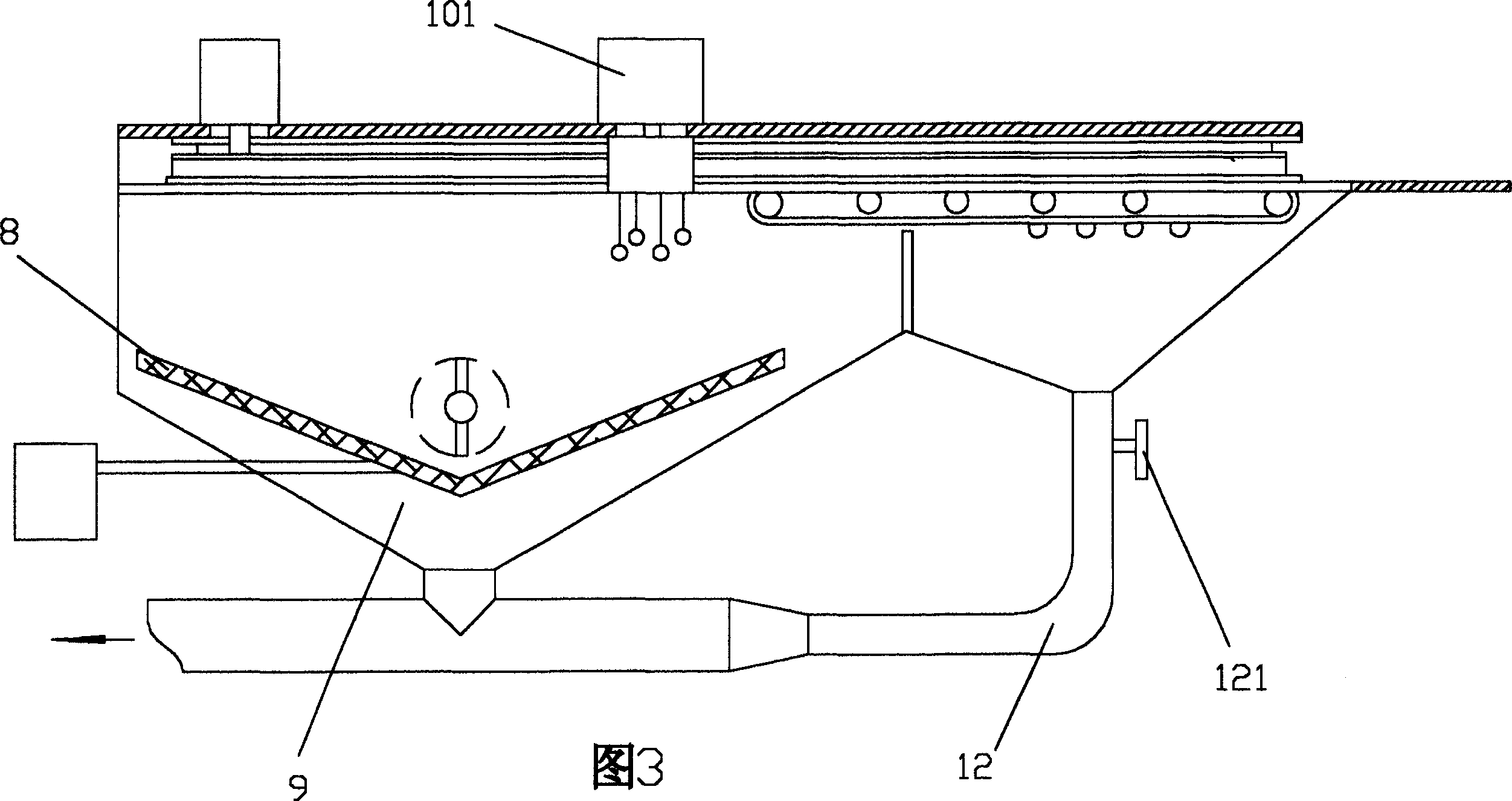

[0013] It can be seen from Fig. 1 and Fig. 2 that the dual-station dust-containing material cleaning bag removal and bag recovery device of the present invention is symmetrically arranged, including a bag synchronous conveying platform 1, a chain conveying mechanism 2, a bag clip 3, and a bag clip opening and closing Mechanism 4, bag inlet 5, discharge chamber 6, material pulverizer 7, grid type vibrating screen 8, powder collecting bin 9, bag vibration mechanism 10, secondary dust removal chamber 11, secondary dust removal chamber negative pressure air duct 12. The main air duct 13, the working table and the empty bag platform 14 are composed of several parts. In this embodiment, the double-station chain transmission mechanism is arranged in the middle of the synchronous transmission platform. Figure 1, Figure 2 and Figure 5 As shown, each bag transfer platform 1 includes a conveyor belt 110, a synchronous transfer wheel unit 120; the chain transfer mechanism 2 includes a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com