Defrosting device of refrigerant loop and rotary compressor for refrigerant loop

A technology for a rotary compressor and a refrigerant circuit, which is applied to the defrosting device of the refrigerant circuit and the rotary compressor for the refrigerant circuit. problems, to achieve the effect of reducing production costs and quickly defrosting the evaporator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

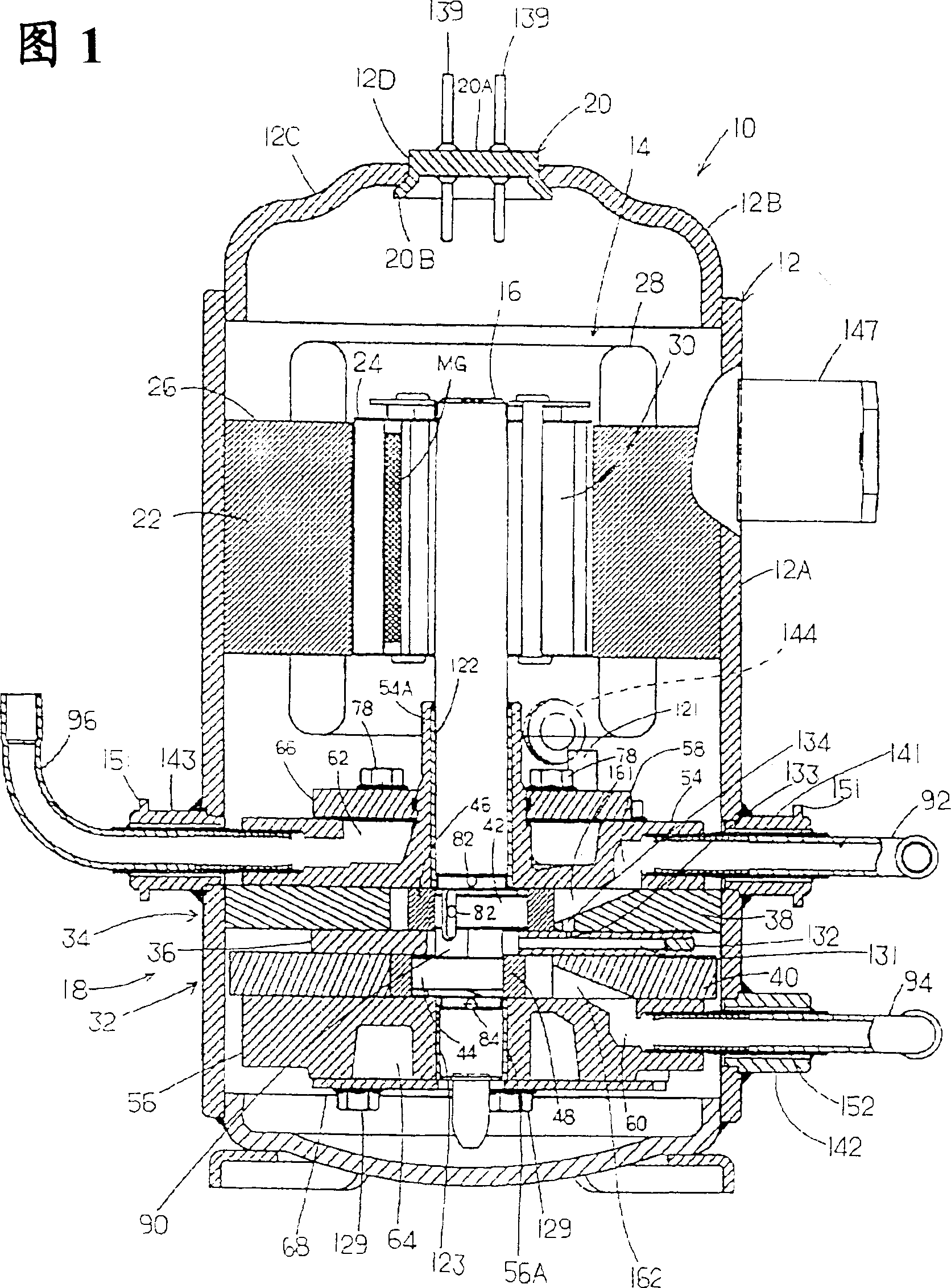

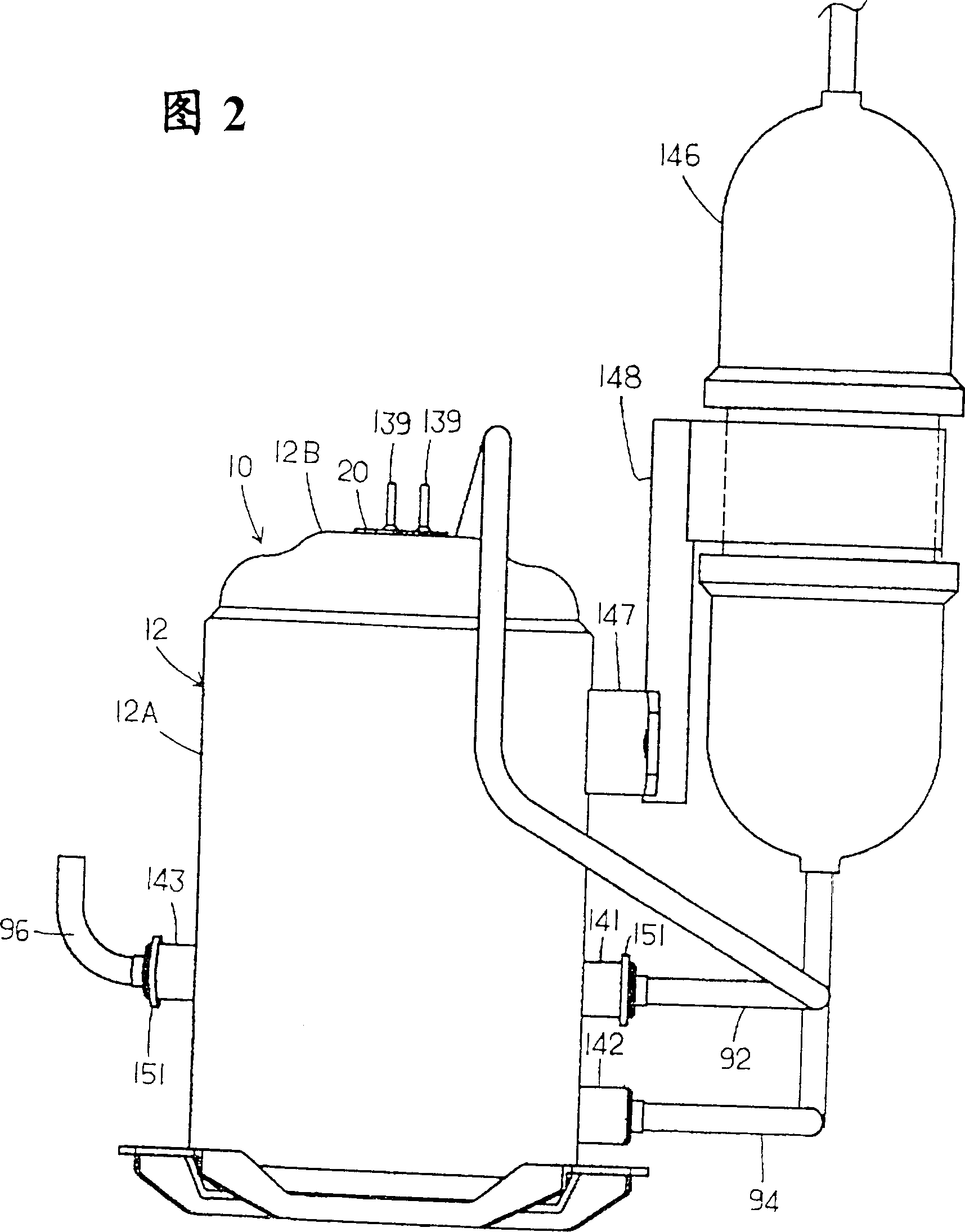

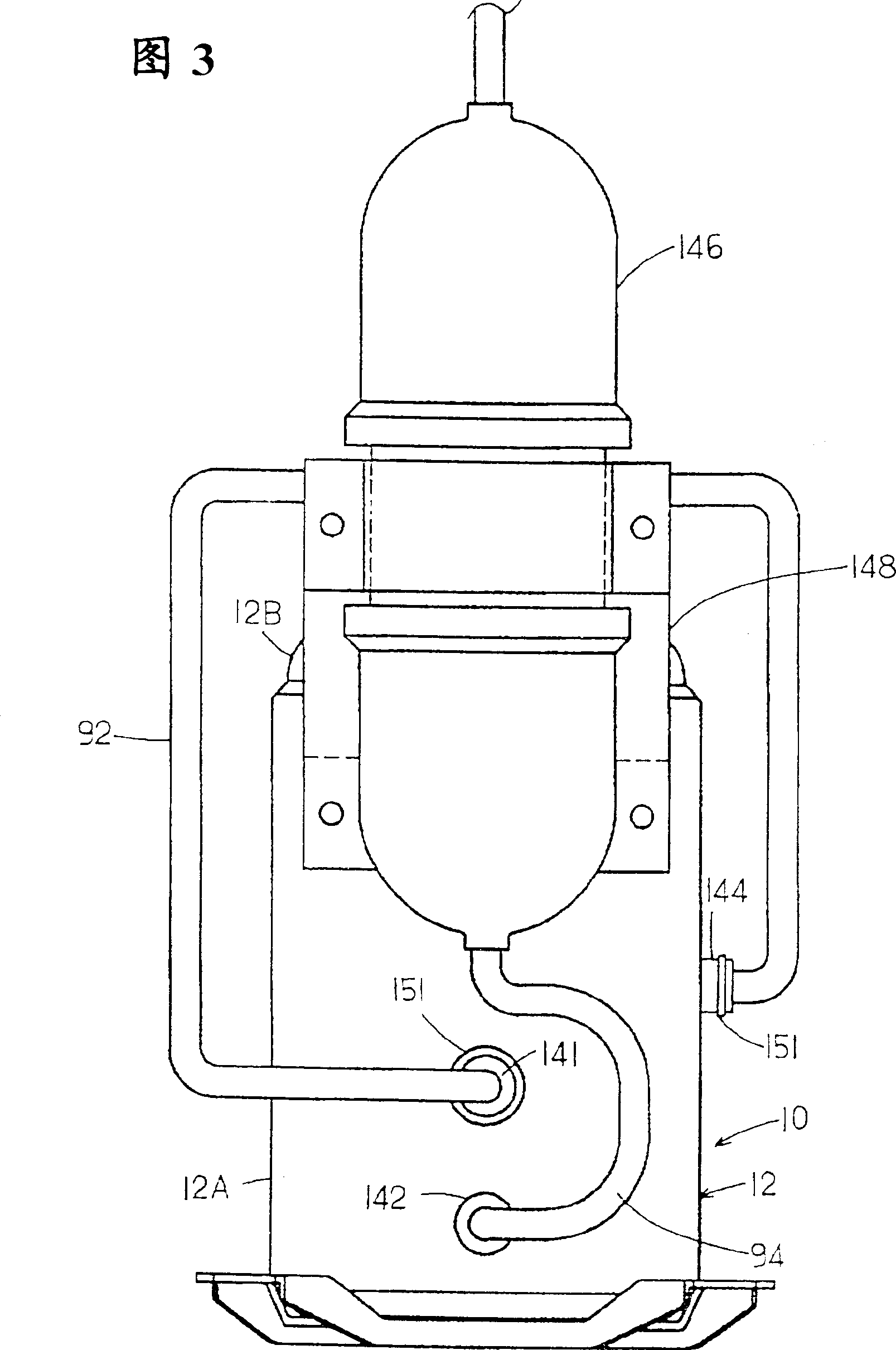

[0056] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. 1 shows a longitudinal sectional view of an internal intermediate pressure multi-stage (two-stage) compression rotary compressor 10 having first and second rotary compression units 32, 34 as an embodiment of the rotary compressor of the present invention. FIG. 2 is a front view of the rotary compressor 10, FIG. 3 is a side view of the rotary compressor 10, and FIG. 4 is another longitudinal sectional view of the rotary compressor 10. Figure 5 is still another longitudinal sectional view of the rotary compressor 10, Figure 6 7 is an enlarged sectional view of the rotary compression mechanism portion 18 of the rotary compressor 10. FIG.

[0057] In each figure, symbol 10 is carbon dioxide (CO 2 ) is an internal intermediate pressure type multi-stage compression rotary compressor used as a refrigerant. The rotary compressor 10 is composed of a cylindrical airtig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com