Self-sticking and elastic bandage for medical use made of woven cloth and its prodn. method

A technology of self-adhesive elastic bandage and production method, which is applied in bandages, adhesives, medical science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2 25g/M2 105D 1∶2 14/ Embodiment 3

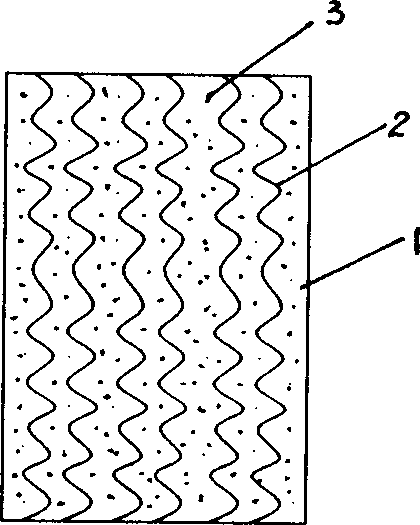

[0052] Non-woven fabric weight Spandex yarn Elasticity ratio Spandex yarn spacing Example 1 10g / M 2 70D 1:1 18 rows / inch Example 2 25g / M 2 105D 1:2 14 rows / inch Example 3 40g / M 2 120D 1:3 9 rows / inch

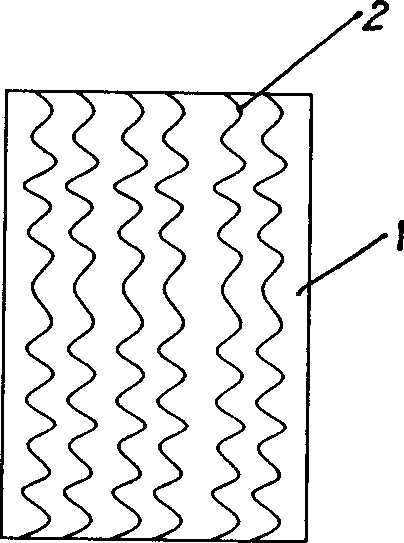

[0053] To use non-woven fabrics to make elastomeric substrates, first of all, choose raw materials that can meet the requirements of medical device dressings. Generally, non-woven fabrics mixed with polypropylene filaments or nylon filaments and polyester filaments are used. These materials have good properties such as softness, breathability, and comfort. Excellent performance, no irritation or allergy to human skin. The non-woven fabric manufacturing process should be hot-rolled or spunlace. These two manufacturing processes can meet the basic requirements of elastic bandages; the thickness of non-woven fabrics can be selected from 10 grams per square meter to 40 grams per square meter; the elasticity of spandex filaments can be 70D or 120D, and the larger t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com