Practical pressure swing adsorption method

A kind of pressure swing adsorption and practical technology, applied in the field of pressure swing adsorption, can solve the problem of not being able to guarantee at the same time, and achieve the effects of improving the utilization rate, improving the recovery rate and increasing the time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

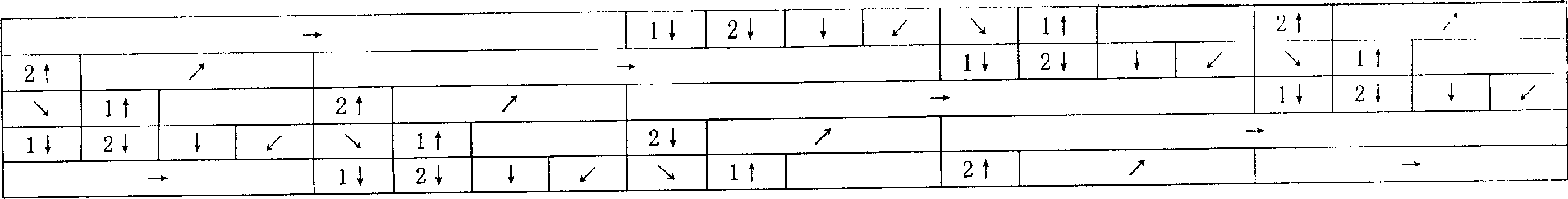

[0024] A practical pressure swing adsorption method, in which each adsorption tower in the pressure swing adsorption process has to undergo adsorption (→), pressure drop (↓), pressure increase (↑), final rise (□) in one cycle Several states, including one of the following states: flushing (□), vacuuming ( ), variable temperature (t) and so on. The present invention comprises M adsorption towers, there are N adsorption towers in the adsorption state, the adsorption tower at the end of the adsorption state and the adsorption tower that will be in the adsorption state perform gas balance, the adsorption tower in the step-down state and the adsorption tower in the boost state For gas balance, the number of times each adsorption tower performs gas balance in a cycle is 2 (M-N), in which the gas equalization boost is M-N times, and the gas equalization depressurization is M-N times, which may improve the utilization of the adsorption tower rate, or increase the number of gas balan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com