Fuel pump assembly

A technology of fuel pumps and components, which is applied in the direction of fuel injection pumps, fuel injection devices, liquid fuel feeders, etc., and can solve the problems of engine fuel supply performance impact, increased assembly steps, time-consuming and expensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Detailed description of the preferred embodiment

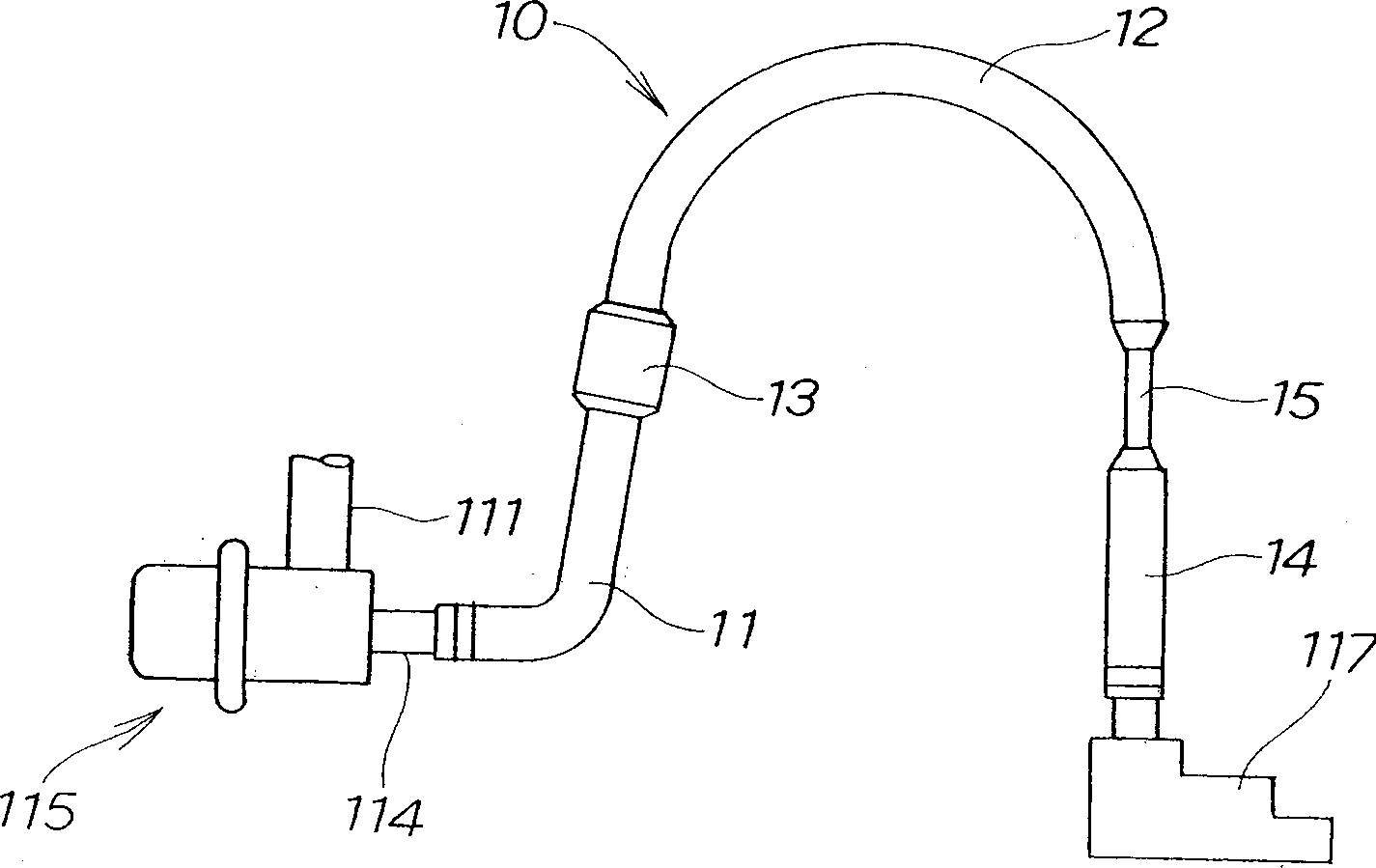

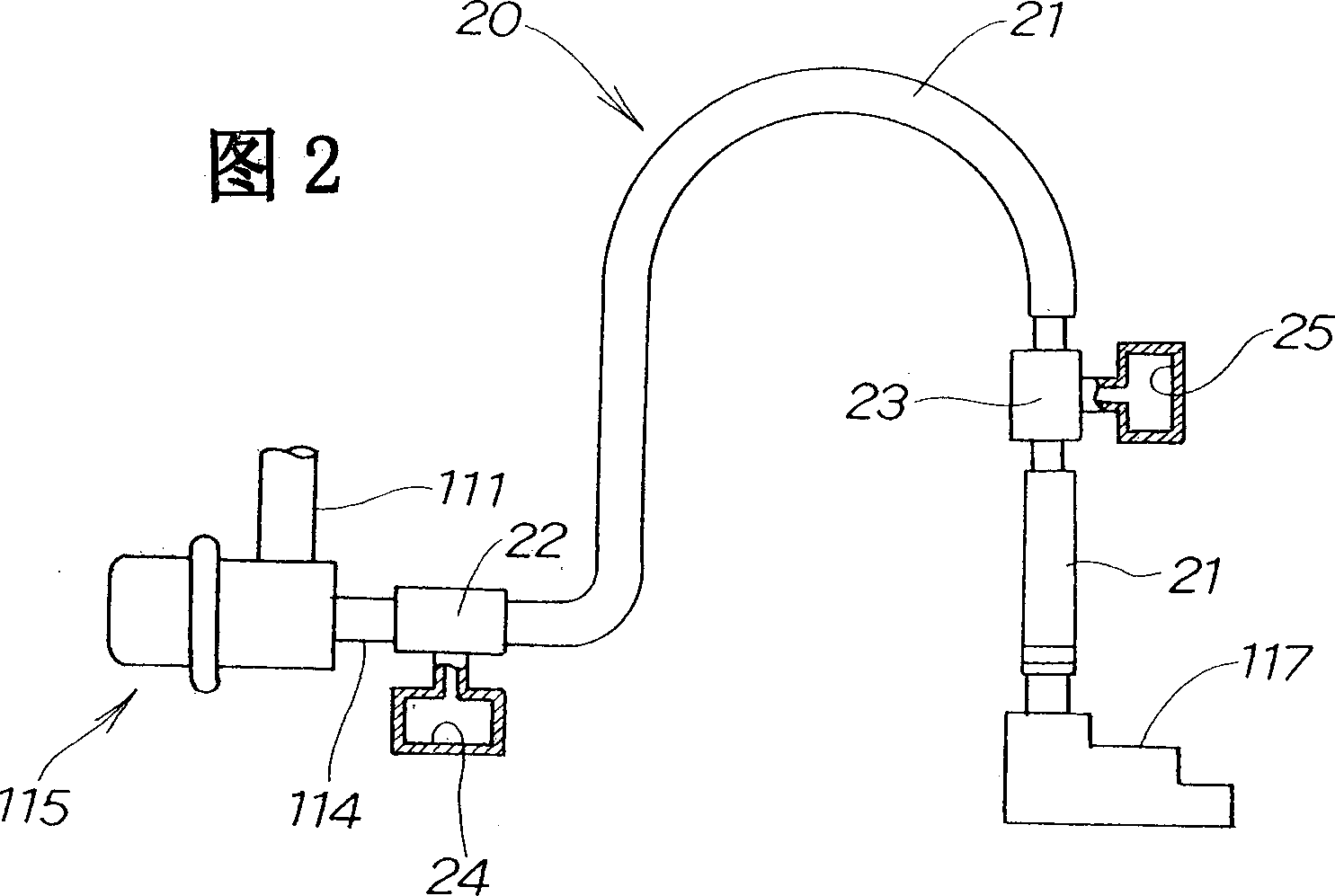

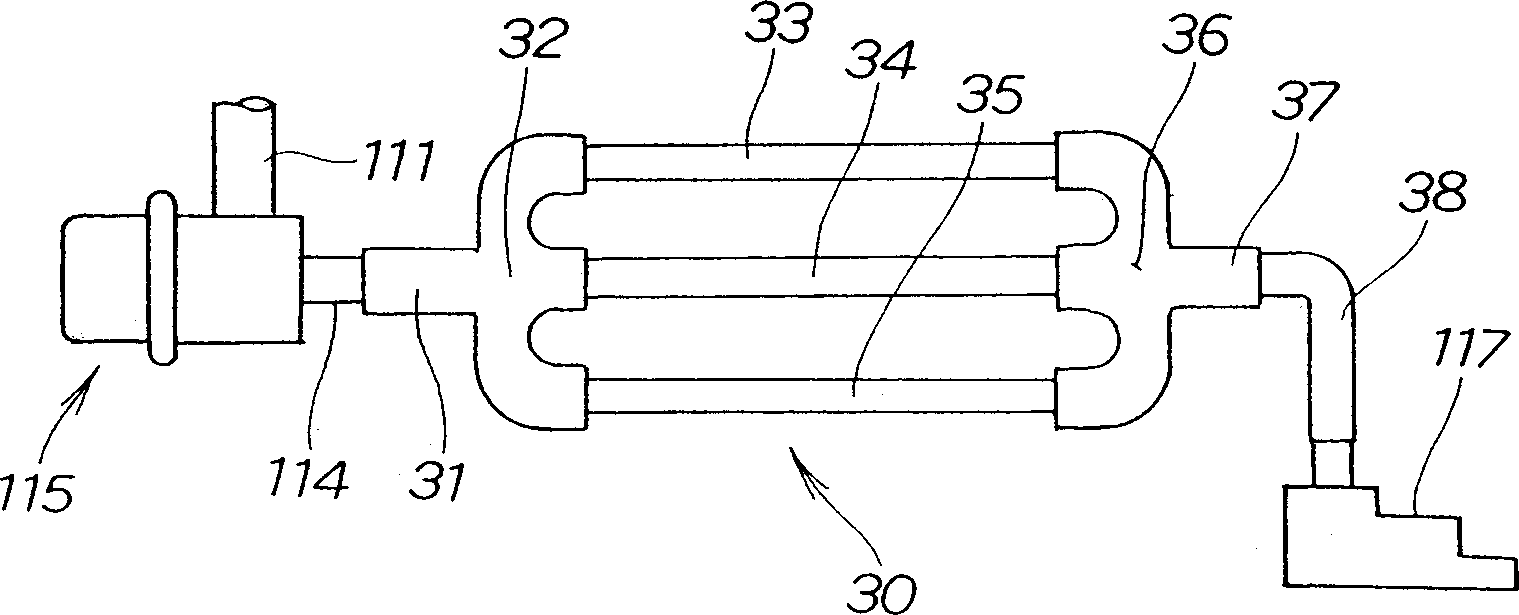

[0027] First refer to figure 1 , which shows an enlarged portion of the fuel pump assembly of the first embodiment. The illustrated fuel pump is a partial modification of the fuel pump assembly shown in Figure 5, and like parts are therefore designated by like reference numerals.

[0028] The first embodiment is characterized by its return pipe 10, which is connected to the outlet 114 of the pressure regulator 115 and the pipe end member 117, the return pipe 10 having a portion 13 of enlarged diameter placed between the plastic pipes 11, 12 Or a reduced diameter portion 15 placed between the plastic tubes 12 , 14 .

[0029] The plastic tubes 11, 12, 14 have a fixed inner diameter so that the flow rate of the fuel does not vary as it passes through them. However, the enlarged diameter portion 13 has a larger inner diameter, ie a larger cross-sectional area, so that the flow velocity is reduced. On the contrary, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com