Coating device and coating method

A coating device and coating technology, applied in the field of rod coating device and rod coating, coating object with rough surface, rod coating device, can solve coating irregularity and coating film interruption , It is difficult to obtain a uniform coating surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example I( example 11-14 and comparative example 11-14

[0214] A carrier sheet W was obtained by blasting one side surface of an aluminum sheet according to a conventional method, and anodizing the blasted surface.

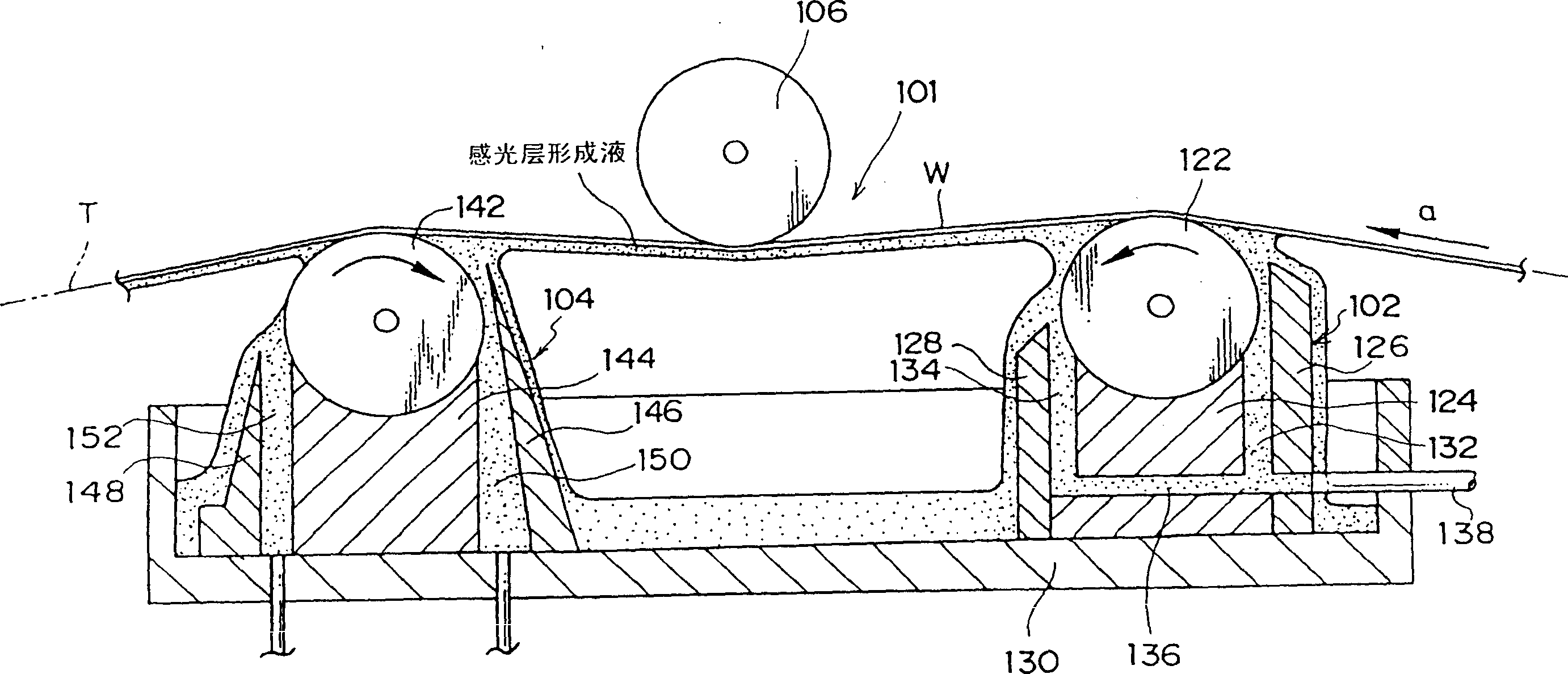

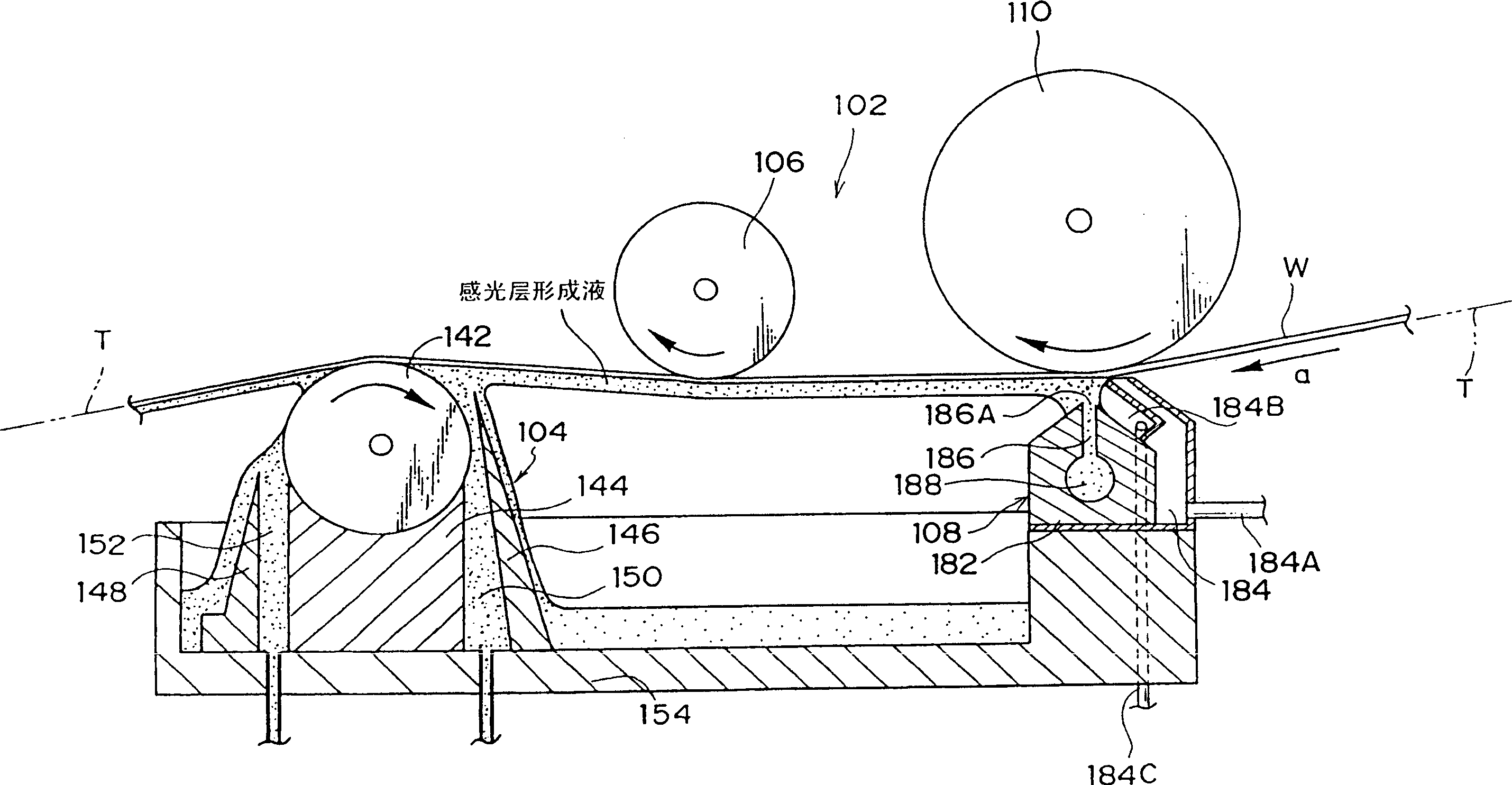

[0215] use figure 1 The illustrated coating device 101 coats a carrier sheet W with a photosensitive layer forming liquid.

[0216] The coating conditions of the photosensitive layer forming liquid are as follows.

[0217] a. Thickness of carrier sheet W: 0.3mm

[0218] b. Conveying speed of carrier sheet W: 150 m / min. Coating amount of rod type coating device 102: 50 cc / m 2 d. Measuring capacity of rod-type dosing device 104: 15cc / m 2 e. Diameter of coating rod 122: 10mm f. Diameter of dosing rod 142: 10 mmg.

[0219] Rod speed(rpm)

quality

Remark

painted pole

Quantitative rod

Example 11

+4770(no driver)

-500

○

Example 12

+300(with driver)

+500

○

Example 13

+4770(no dri...

example II

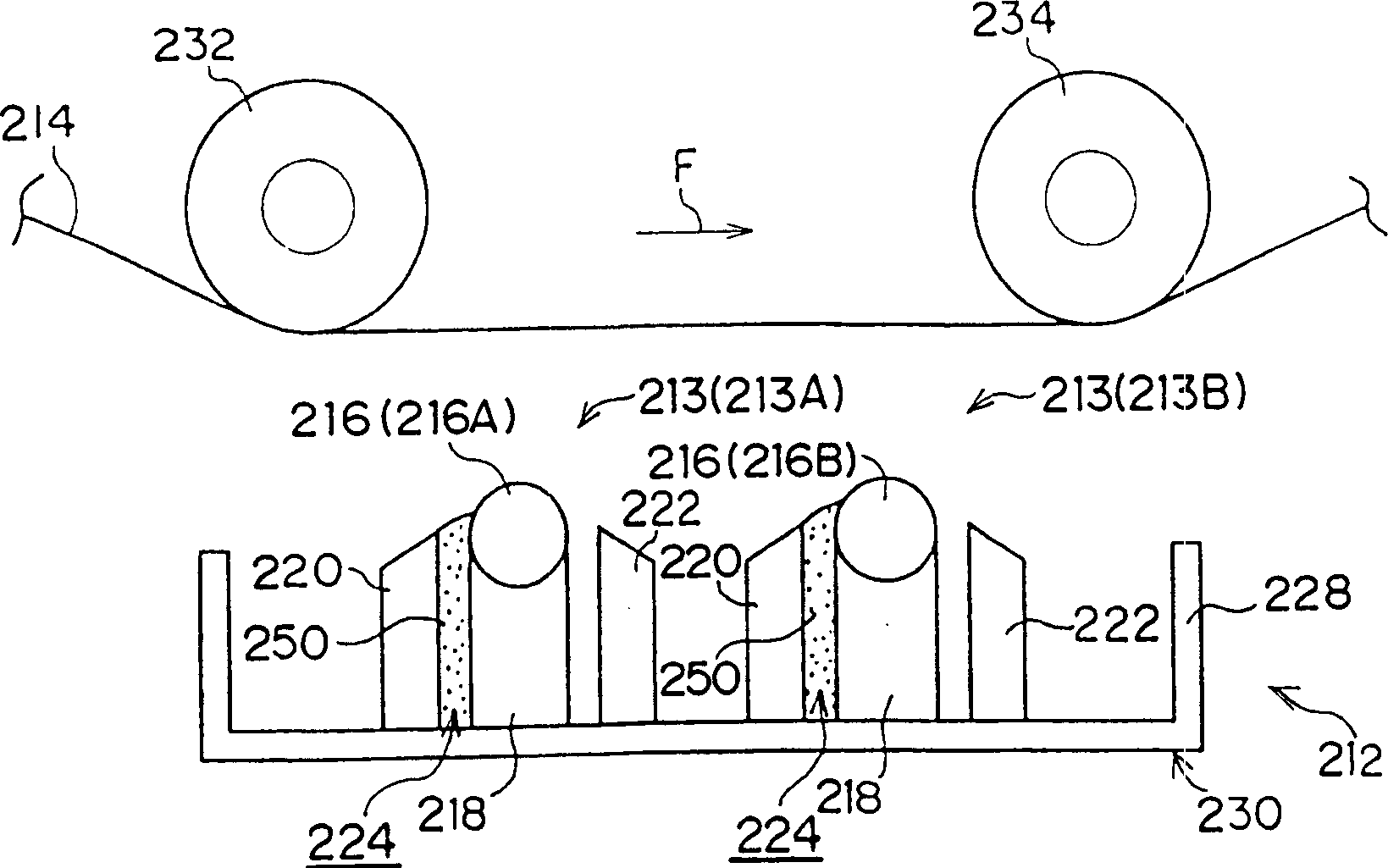

[0276] In this example, the coating liquid 250 is coated on the aluminum sheet 214 by the rod coating device 212 of the present invention.

[0277] First, implement mechanical roughening treatment, chemical etching treatment, electrolytic roughening treatment and anodic oxidation treatment on the surface of the strip-shaped aluminum plate to obtain a substrate (aluminum sheet 214) with an arithmetic mean roughness Ra of 0.20 μm and an arithmetic mean A substrate (aluminum sheet 214) having a roughness Ra of 0.26 μm. The aluminum sheets 214 were applied with the coating liquid 250 by the rod coating device 212, their coated surface quality was evaluated, and the state of the coated surface was observed.

[0278] The coating conditions are as follows.

[0279] a. Width of aluminum sheet: 500mm

[0280] b. Thickness of aluminum sheet: 0.3mm

[0281] c. Conveying speed: 150m / min

[0282] d. Coating amount

[0283] Preliminary coating rod: 0.051 / m 2

[0284] Adjustment (meas...

example III

[0305] In this example, the coating liquid 250 is coated on the aluminum sheet 214 by the rod coating device 212 of the present invention.

[0306] First, mechanical roughening, chemical etching, electrolytic roughening, and anodizing were performed on the surface of the strip-shaped aluminum plate to obtain a substrate (aluminum sheet 214) having an arithmetic average roughness Ra of 0.48 μm. The aluminum sheet 214 was applied with the coating liquid 250 by the rod coating device 212, the quality of its coated surface was evaluated, and the state of the coated surface was observed.

[0307] The coating conditions are as follows.

[0308] a. Width of aluminum sheet: 500mm

[0309] b. Thickness of aluminum sheet: 0.3mm

[0310] c. Conveying speed: 150m / min

[0311] d. Coating amount: 0.021 / m 2

[0312] e. Coating rod diameter: 10mm (both)

[0313] f. Coating rod revolutions

[0314] Preliminary coating rod: Same speed and direction as aluminum sheet (driven rotation)

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com