Refrigerator

A technology for refrigerators and refrigerator bodies, which is applied to household refrigerators, coolers, lighting and heating equipment, etc., can solve problems such as increased costs, larger refrigerators, and smaller compartment capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

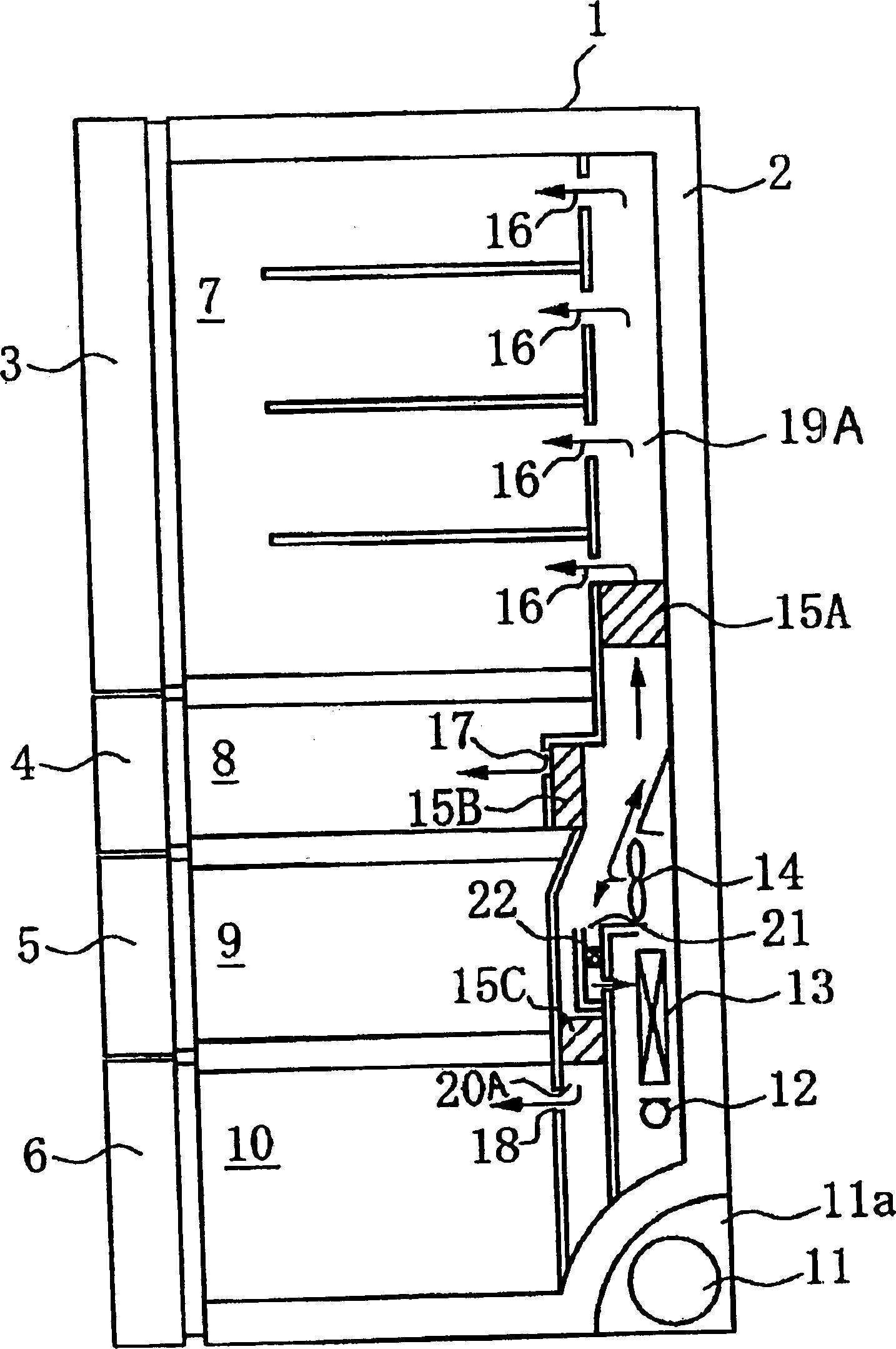

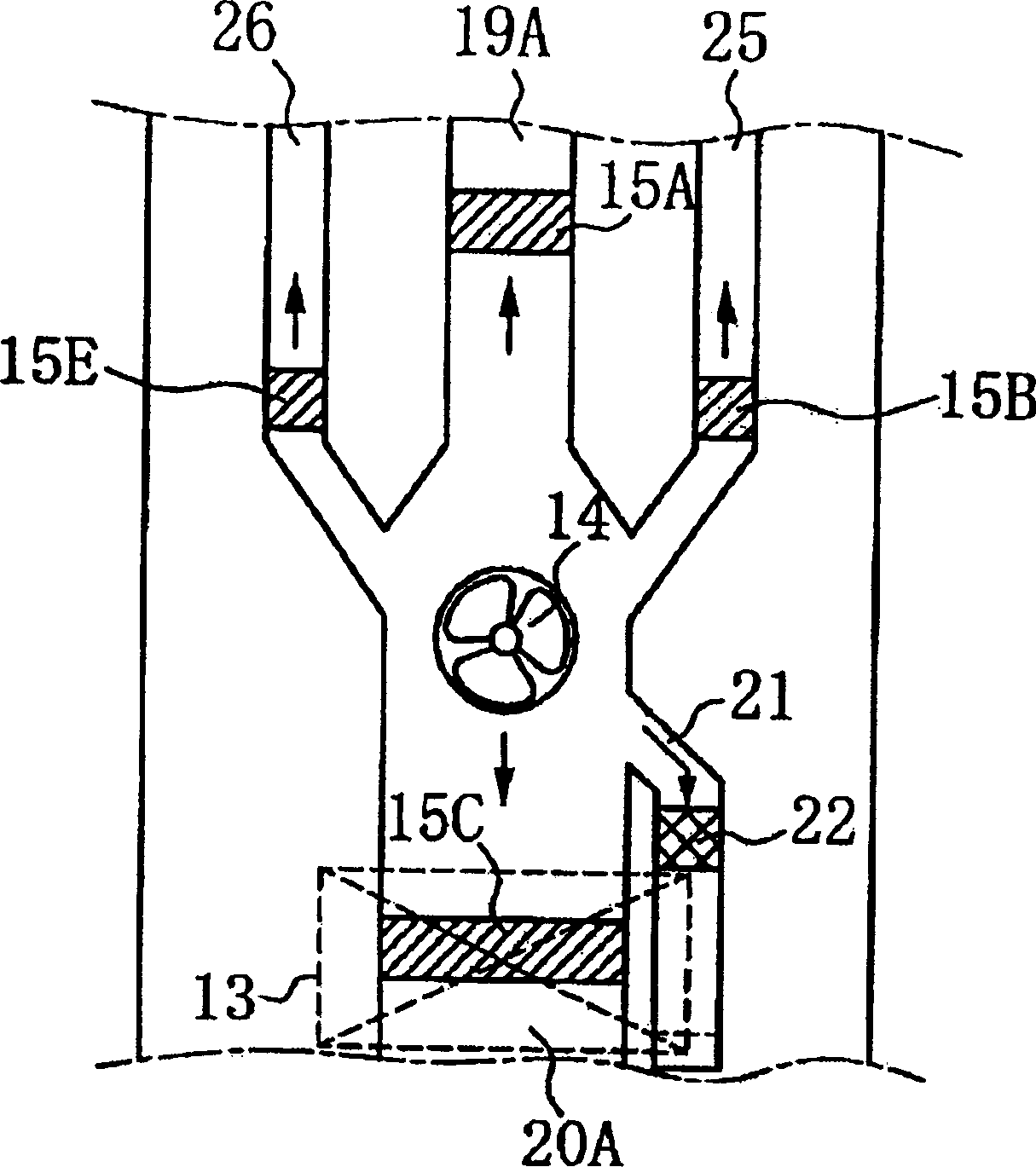

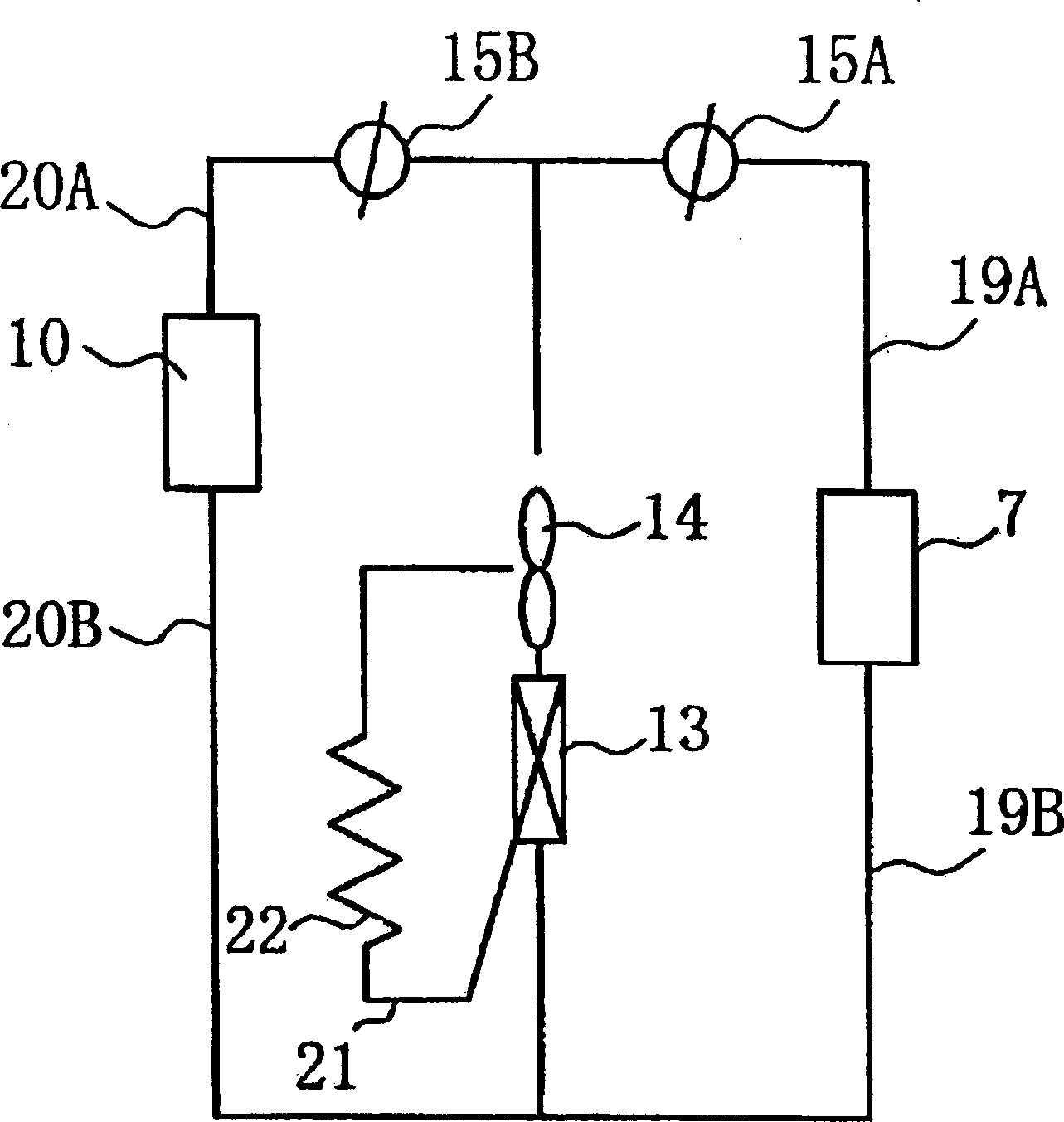

[0066] use Figure 1 to Figure 5 Embodiment 1 of the present invention will be described. figure 1 It is a side sectional view showing the refrigerator of Example 1 of this invention. 1 is the main body of the refrigerator, and 2 is the heat insulation box filled with heat insulation material. 7 is a refrigerating chamber installed on the upper part of the refrigerator body 1, 8 is a switching chamber installed under the refrigerating chamber 7, and can be switched over a wide range of temperature ranges from vegetables to frozen foods, and 9 is a switching room installed in the switching room 8. Bottom, a vegetable compartment for preserving vegetables and the like, 10 is a freezer compartment which is arranged under the vegetable compartment 9 and preserves frozen foods and the like.

[0067] 3 is an openable door for a refrigerator compartment installed in front of the refrigerator compartment 7, 4 is a door for a pull-out switch compartment installed in front of the swit...

Embodiment 2

[0087] use Figure 7 ~ Figure 10 Embodiment 2 of the present invention will be described. Figure 7 It is a side sectional view of the refrigerator which shows an example of Embodiment 2 of this invention. Figure 8 It is a main part front view which shows a part of the air duct of the refrigerator of Example 2. Figure 9 It is a schematic wind path diagram which shows the schematic structure of the air path of the refrigerator of Example 2. exist Figure 7 , Figure 8 , Figure 9 In , the same parts as those in Embodiment 1 are marked with the same symbols and their descriptions are omitted. In this embodiment, a deodorizing baffle 15D for adjusting the flow rate passing through the bypass flow path 21 is provided in the bypass flow path 21 of the refrigerator main body 1 of the first embodiment.

[0088] exist Figure 7 , Figure 8 , Figure 9 Among them, 15D is a special deodorizing baffle installed in the bypass flow path 21. Since the deodorizing special baffle 1...

Embodiment 3

[0106]In this embodiment, all the cold air volume adjustment baffles provided in the refrigerator body 1 described in the second embodiment have the opening degree adjustment function. Fig. 11 is a control flowchart showing a control flow of the deodorizing device of the refrigerator according to the third embodiment. In the figure, S50 is a step of selecting a compartment for deodorizing operation, for example, a step of selecting a refrigerating room deodorizing operation when deodorizing operation of the refrigerating room 7 is selected. S51 is a deodorization operation switch activation step for activating the deodorization operation switch of the compartment (refrigerator compartment 7) selected in S50, and S52 is a defrosting operation determination step for determining whether the refrigerator is in defrosting operation.

[0107] S71 is a deodorizing operation refusal step for rejecting the deodorizing operation when it is judged that the defrosting operation is in prog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com