Heat treatment furnace and its temp.-controlling method

A heat treatment method and technology of a heat treatment furnace, applied in the field of heat treatment furnaces, can solve the problems of destroying temperature distribution, increasing the magnitude of convection, large convection, etc., and achieve the effects of easy maintenance and operation, precise temperature control, and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

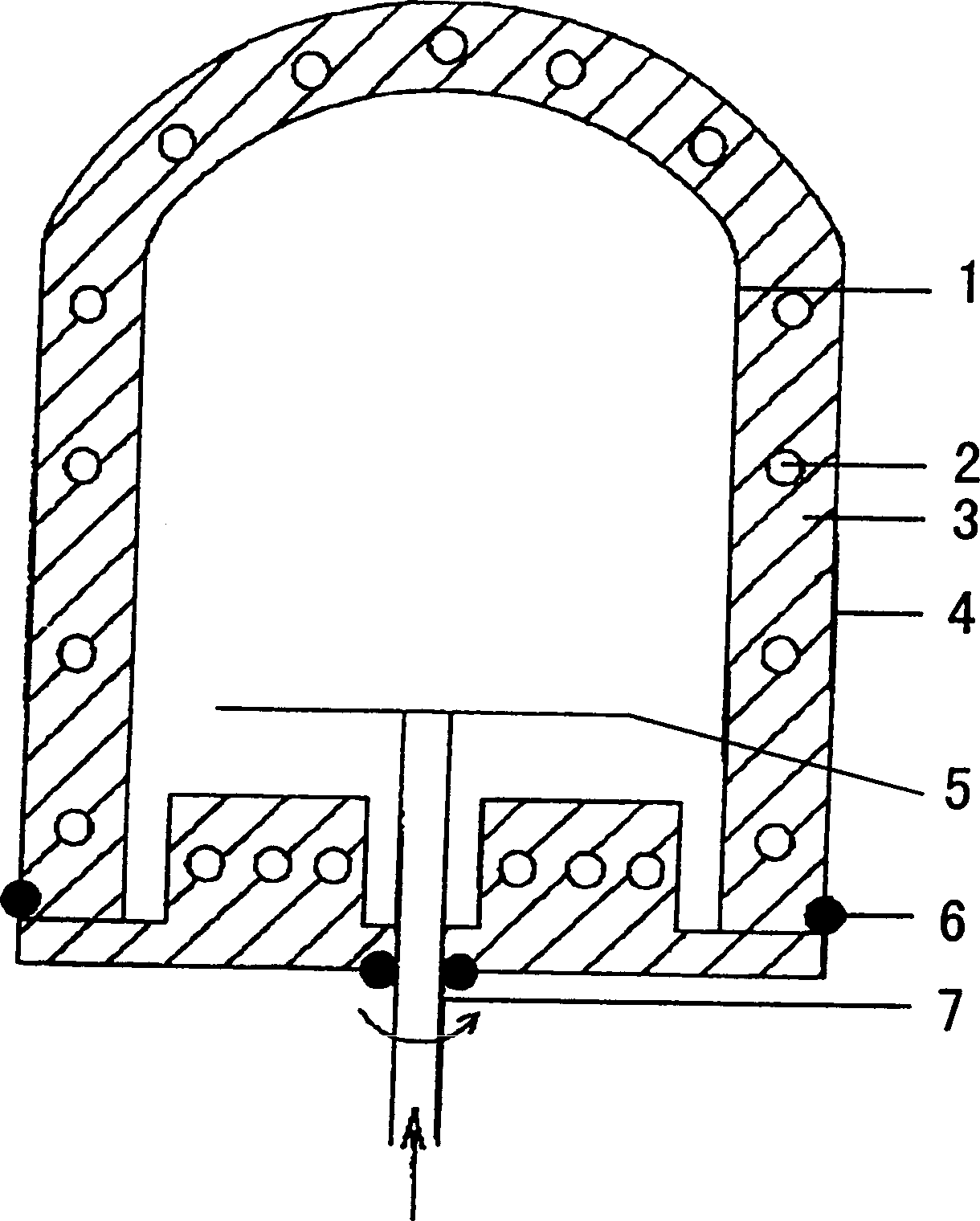

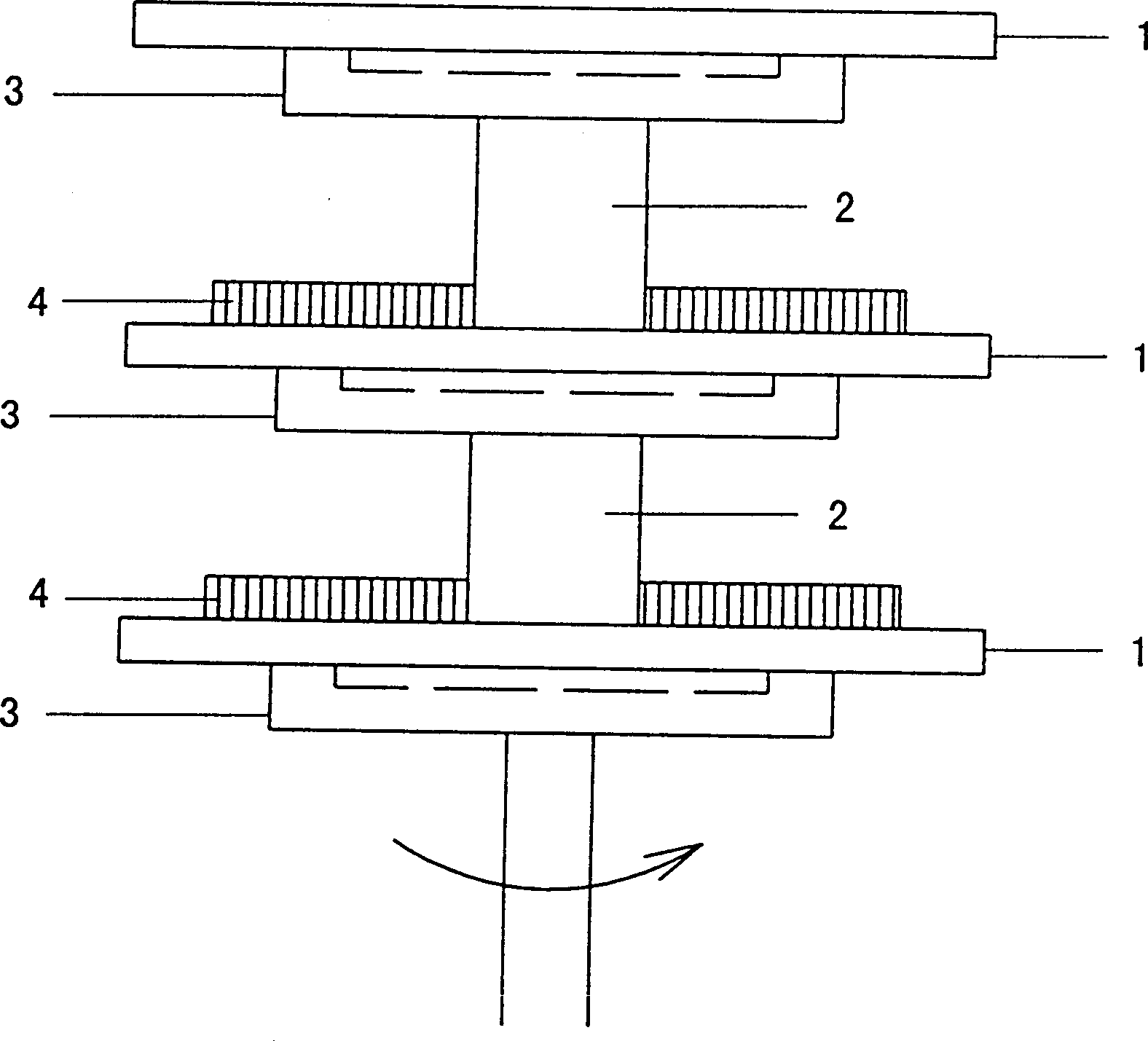

[0018] According to the vertical furnace of the present invention such as figure 1As shown, it includes: a furnace cover 1, a heating plate 2, a thermal insulation layer 3, a furnace shell 4, a sample support system 5, a sealing ring 6 and a rotating shaft 7. It is used to heat-treat the silver-coated Bi-2223 multi-core strip material of the high-temperature superconducting wire (hereinafter referred to as the bismuth-based strip material), so as to obtain the bismuth-based strip material with higher critical current density. The diameter of the furnace is 1m, and the volume is about 1m 3 , The furnace wall is composed of a furnace inner cover, a heating layer, a thermal insulation layer, and a furnace shell. The furnace wall is equipped with a water-cooling or air-cooling system, and it can also be cooled naturally. Low oxygen partial pressure is used in the furnace, and the oxygen bias is controlled by controlling the concentration, flow and flow rate of oxygen. The annea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com