Prefabricated fiber rod with several clad layers and its fabrication

A technology of an optical fiber preform and a manufacturing method, which is applied in the field of optical fiber manufacturing, can solve the problems of high optical fiber manufacturing cost, high proportion of high-purity raw materials, and high proportion of optical fiber manufacturing cost, and achieves the effect of reducing raw material cost and manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

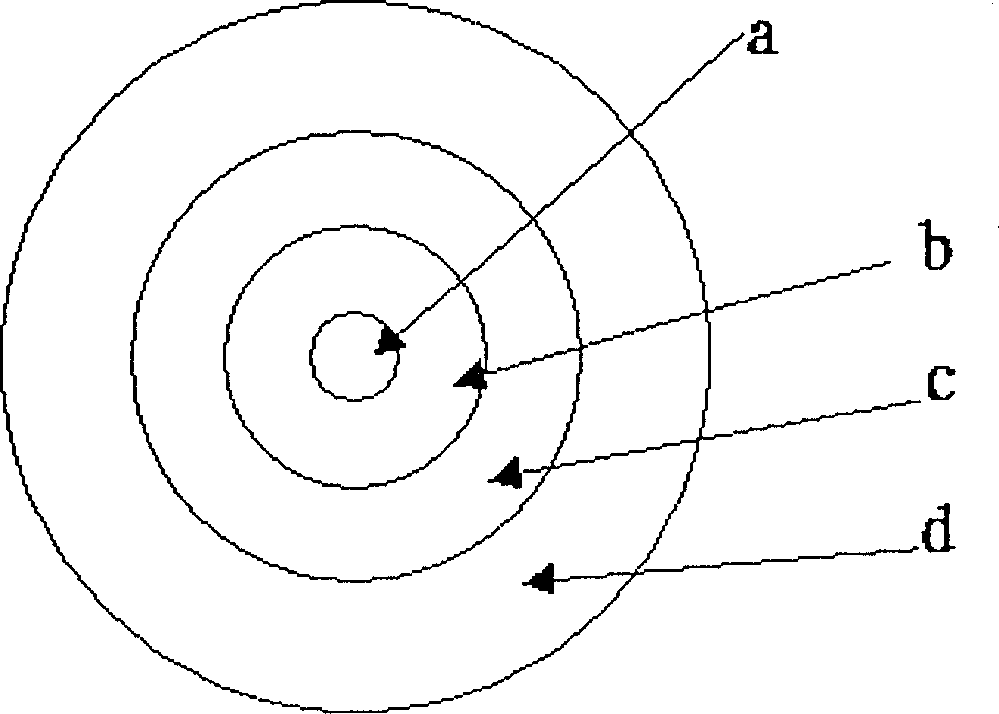

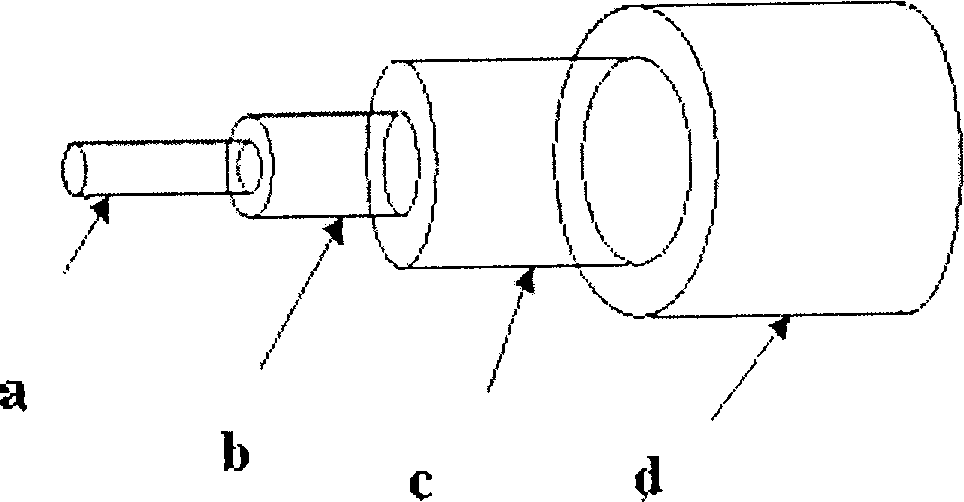

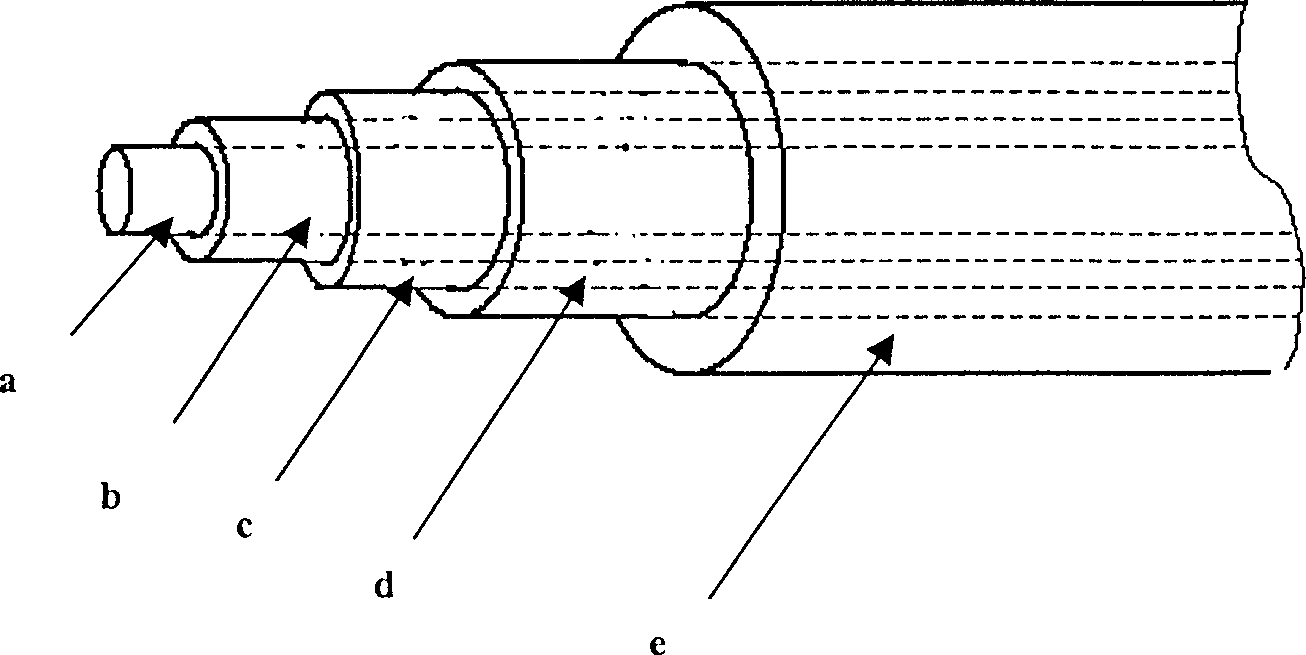

[0048] The ratio of the outer diameter B of the inner cladding layer b to the outer diameter A of the core layer a is 1.0;

[0049] The ratio of the outer diameter C of the low-hydroxyl high-purity cladding c to the outer diameter A of the core layer a is 2.0;

[0050] The ratio of the outer diameter D of the high-purity outer cladding layer d to the outer diameter A of the core layer a is 5.0;

[0051] The ratio of the outer diameter E of the sub-high purity outer cladding layer e to the outer diameter A of the core layer a is 13.5;

[0052] Among them, the high-purity outer cladding d is made of high-purity SiCl with a content of 99.99% 4 Prepared, the sub-high purity outer cladding e is made of SiCl with a content of 99.9% 4 It is prepared, and the outer diameter E of the sub-high purity outer cladding e is 60mm.

[0053] The present invention adopts following implementation mode to be preferred implementation mode:

[0054] The ratio of the outer diameter B of the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com