Turbine blade arrangement

A technology for turbine blades and blades, applied in the direction of supporting elements of blades, machines/engines, leakage prevention, etc., to achieve the effect of firm clamping, simple connection, and good force distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

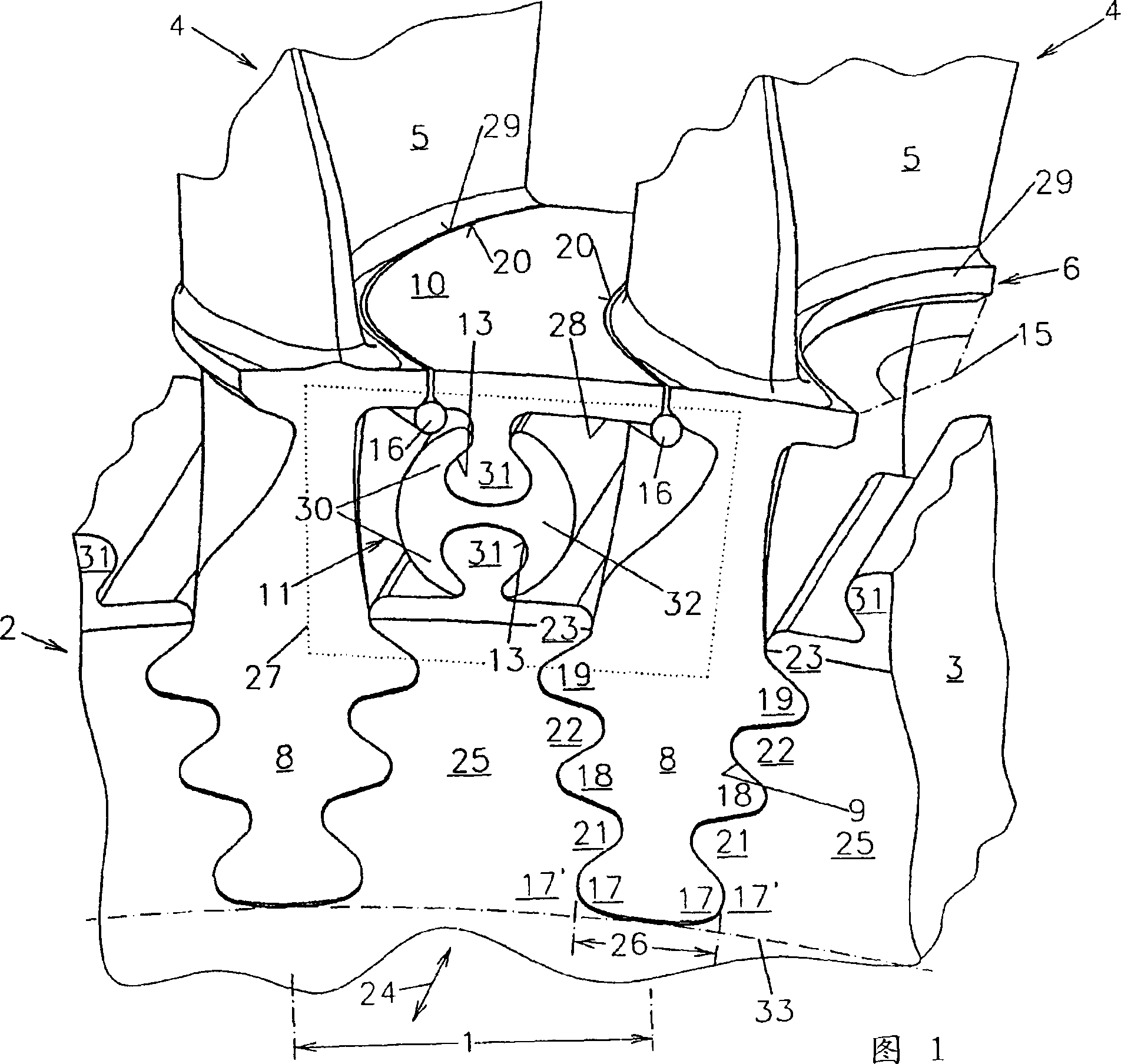

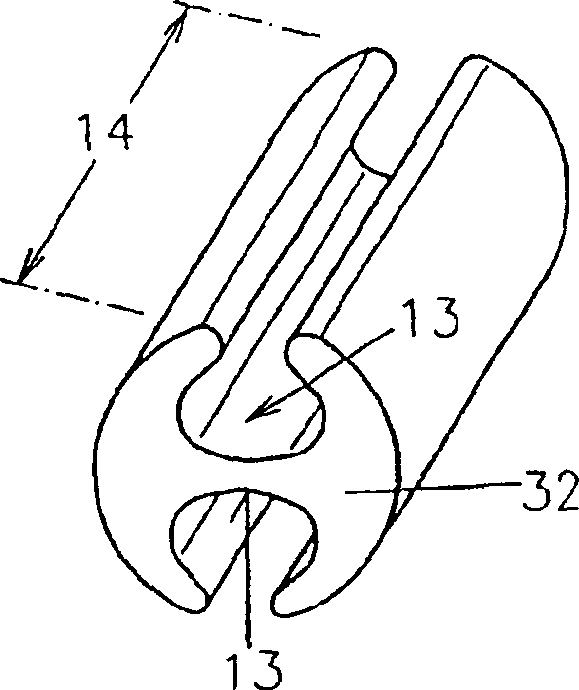

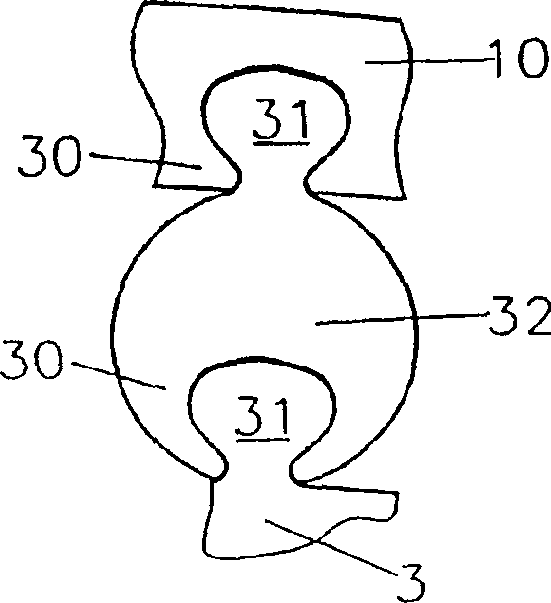

[0020] Figure 1 shows a perspective view of a turbine blade arrangement. The turbine disk 3 with the rotating blades 4 is driven in rotation about the turbine shaft 24 by means of a hot working fluid, especially hot gas in a gas turbine, passing through the turbine and onto the airfoil 5 . The rotating blades 4 are inserted with their pine-like roots 8 into the grooves 9 with the spacing 1 on the outer circumference 2 of the turbine disk 3 by lateral pushing. As a result of the rotational movement of the turbine disk 3 , the rotating blades 4 are acted upon by centrifugal forces directed towards the outside. This centrifugal force is absorbed by the roots 8 of the rotating blades 4 and the claws 25 of the turbine disk 3 by means of various teeth 17, 18, 19, 21, 22, 23 formed on the roots 8 in a pine tree-like manner and resting on the claws. 25 have integrally formed parts corresponding to them. The bottom root teeth 17 on both sides of the root 8, the middle root teeth 18 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com