Battery

A battery and battery shell technology, applied in the direction of circuits, battery pack parts, electrical components, etc., can solve the problems of hindering resin flow, battery economic loss, difficult to decompose and reuse, etc., to prevent unsightly, high filling efficiency, improve The effect of product manufacturing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

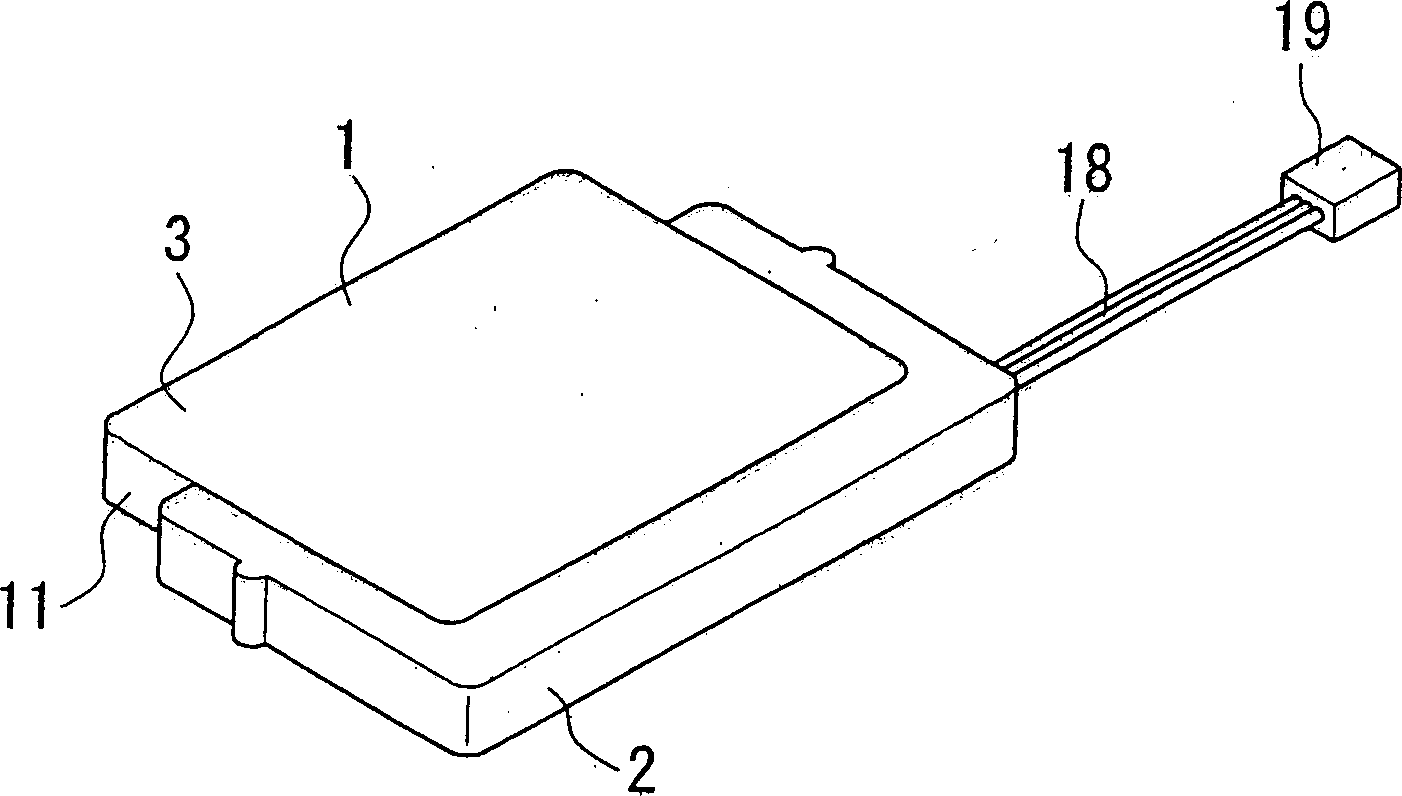

[0026] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. figure 1 , figure 2 In the case where the present invention is applied to a battery for a portable terminal, the battery A for a portable terminal shown in these figures has a battery case 1 and a circuit board 5 disposed along the side surface 4 of the battery case 1, and the circuit board 5 is constituted by The molding part 2 is fixed on the battery case 1, and its basic structure is the same as that of the above-mentioned Figure 4 , Figure 5 Same as shown.

[0027] In addition, in Figure 1 ~ Figure 3 in, right with Figure 4 , Figure 5 The parts shown with the same structure are attached with the same reference numerals and will not be described. Below, only the Figure 4 , Figure 5 different parts.

[0028] Portable terminal battery A with Figure 4 , Figure 5 The difference in structure is the size relationship between the circuit board 5 and the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com