Band core weaving method of solid core apron band

A technology for conveyor belts and belt cores, applied in conveyors, textiles, papermaking, fabrics, etc., can solve the problems of inability to produce high-strength conveyor belts, wide-width conveyor belts, and limited capacity of opening mechanisms, etc., to improve the support situation , The distribution density of the warp line is reduced, and the structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

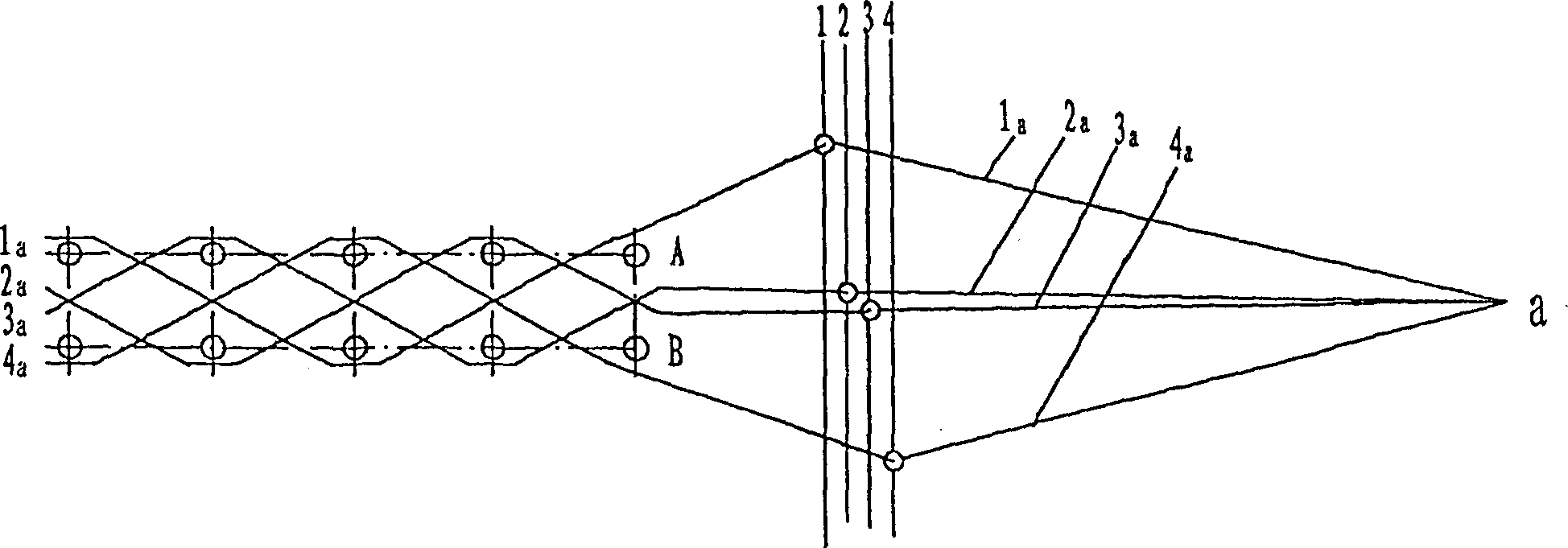

[0017] Such as figure 2 As shown, the conveyor belt is fed into two pairs of warp threads by an entrance a. Weft threads B are bundled together; at the first row (horizontal direction is layer, vertical direction is row), the first warp thread 1a is on the first layer of weft thread A, and the fourth warp thread 4a is under the second layer of weft thread B , and the second warp 2a and the third warp 3a are in the middle of the first layer of weft A and the second layer of weft B, at this moment the first warp 1a and the fourth warp 4a are binding two layers of weft A, B; At the second row, the first warp thread 1a descends and the fourth warp thread 4a rises to the middle of the two layers of weft threads A and B, while the second warp thread 2a rises above the first layer of weft thread A, and the third warp thread 3a descends to Two layers of weft threads A and B are bundled under the second layer of weft threads B. In this way, the alternating and alternating binding has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com