Plate shape body transport box, foam forming method and foam forming device

A technology of foam forming and transportation boxes, which is applied in the direction of transportation and packaging, types of packaging items, special packaging items, etc., can solve the problems of difficult loading, damage, and bad influence on the performance of PDP substrates, etc., and achieve good formability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

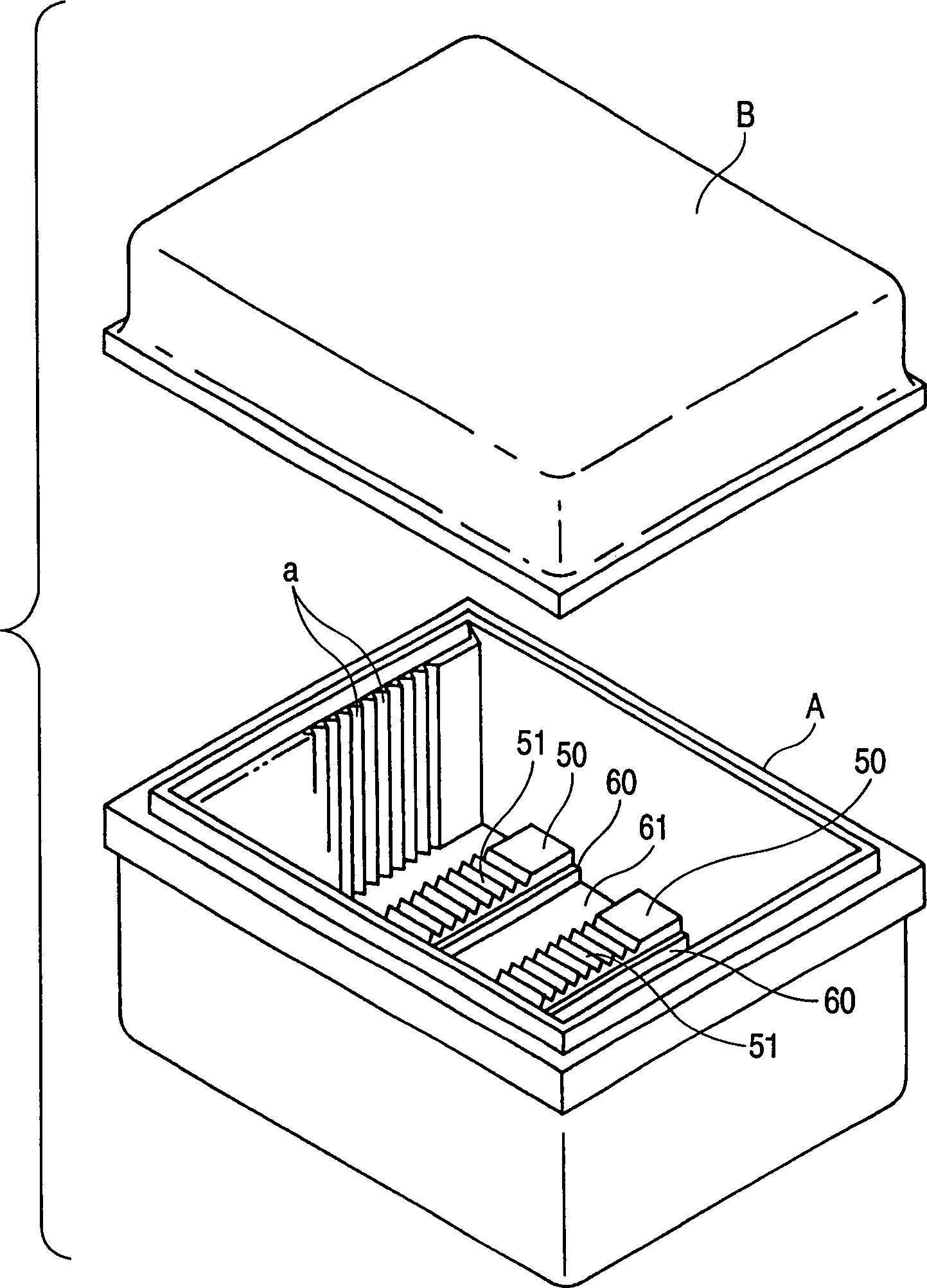

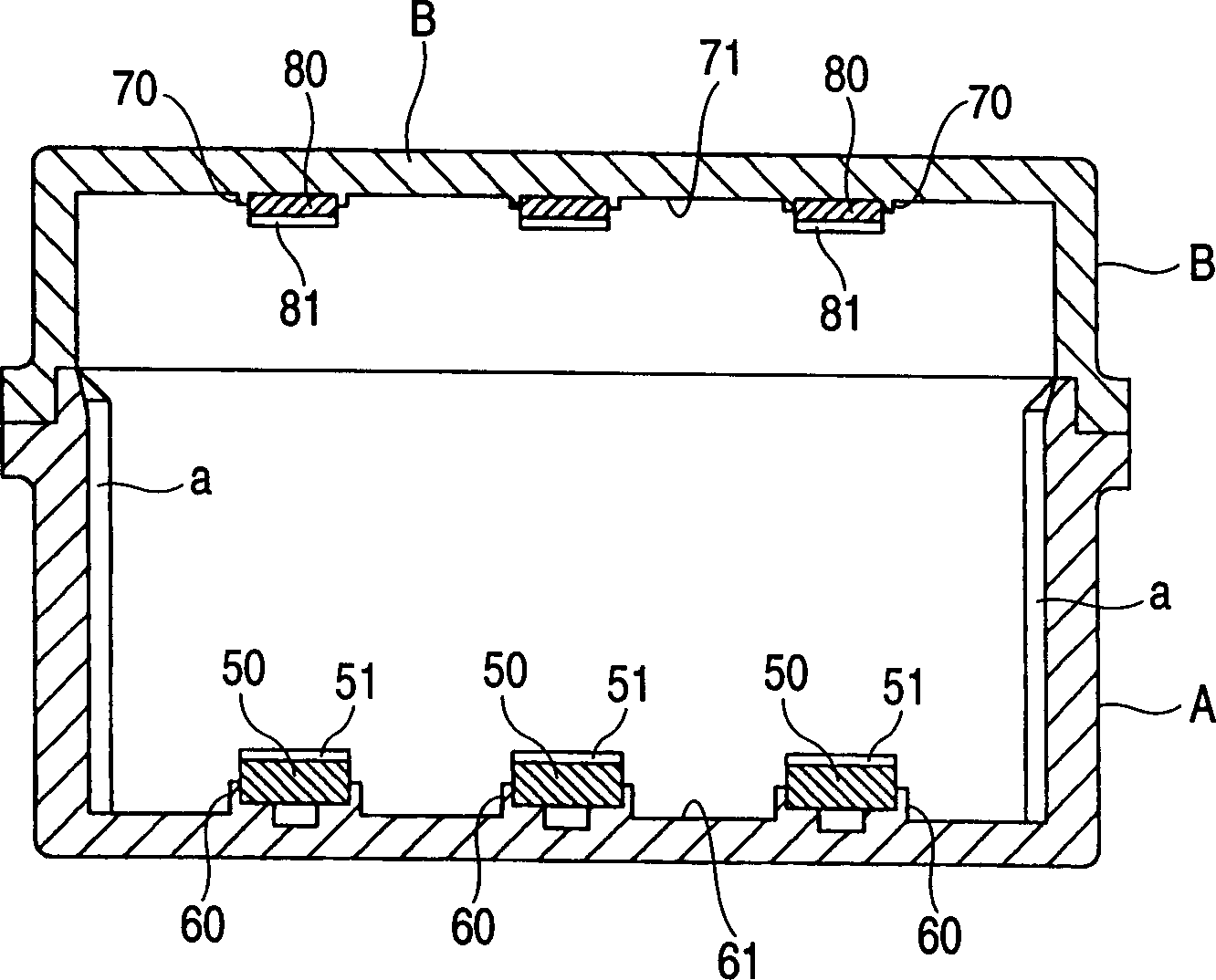

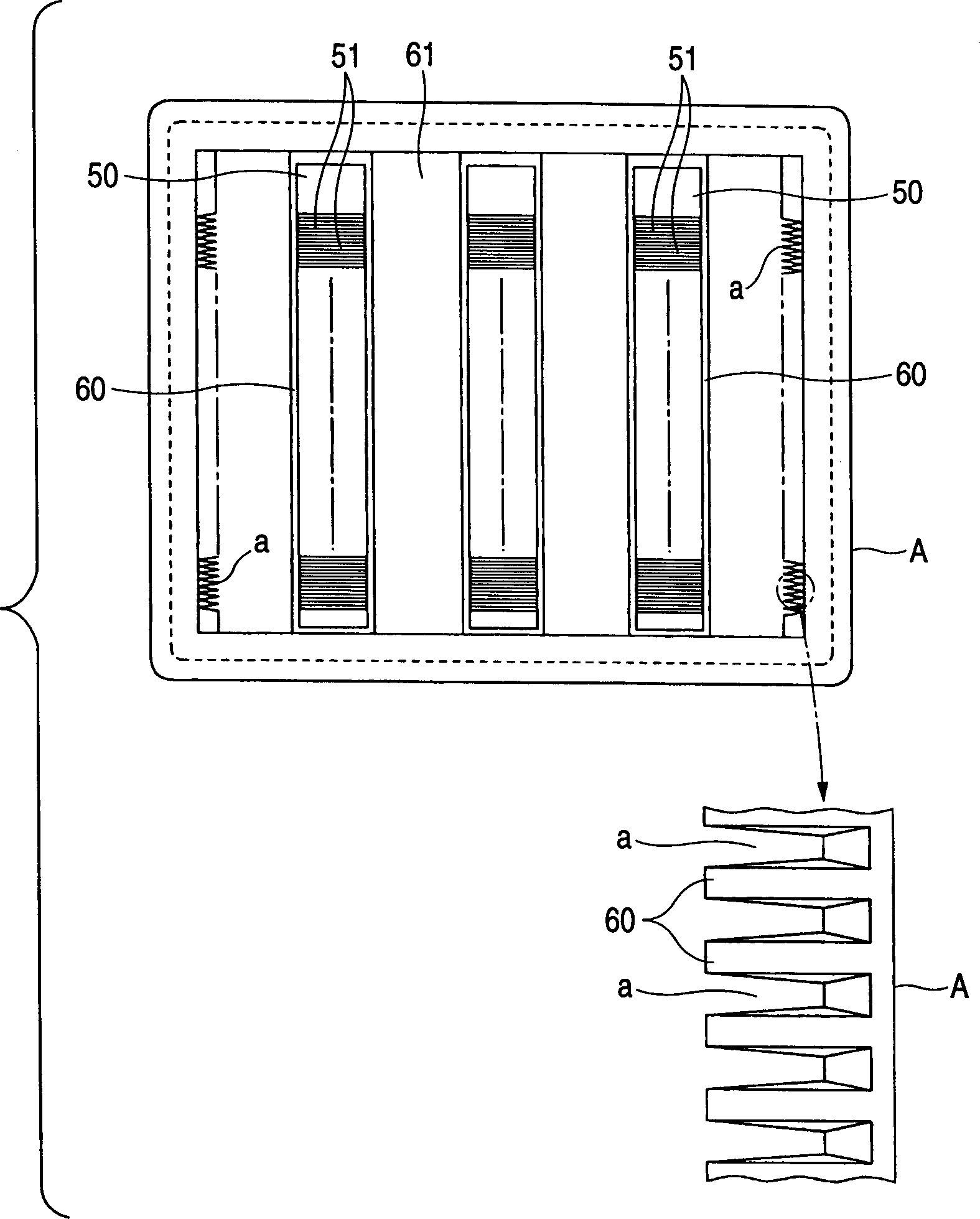

[0032] Embodiments of the present invention are illustrated below with reference to the accompanying drawings.

[0033] exist figure 1 In the oblique view, A represents the body, and B represents the cover. As any thermoplastic resin foam foam, it is preferable to use styrene-modified polyolefin series resin foam foam for foam molding. The above-mentioned body A has a depth of more than 400 mm, and a plurality of grooves a for supporting plate-like objects are formed on a group of opposite inner sides of the inner surface. The groove a is in figure 1 In the main body A, only the inner side of the groove a can be seen, and the groove a is also formed on the invisible inner side. figure 2 This point of view can be clearly understood from the sectional view of the cover state of the cover B. Moreover, 50 in the figure is a support body with a groove 51 embedded in the elongated embedded part 60 formed on the bottom 61 of the body A, and the groove 51 can partially support the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com