Thread wiring terminal

A terminal and screw technology, applied in the field of screw terminals, can solve problems such as unbalanced terminals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

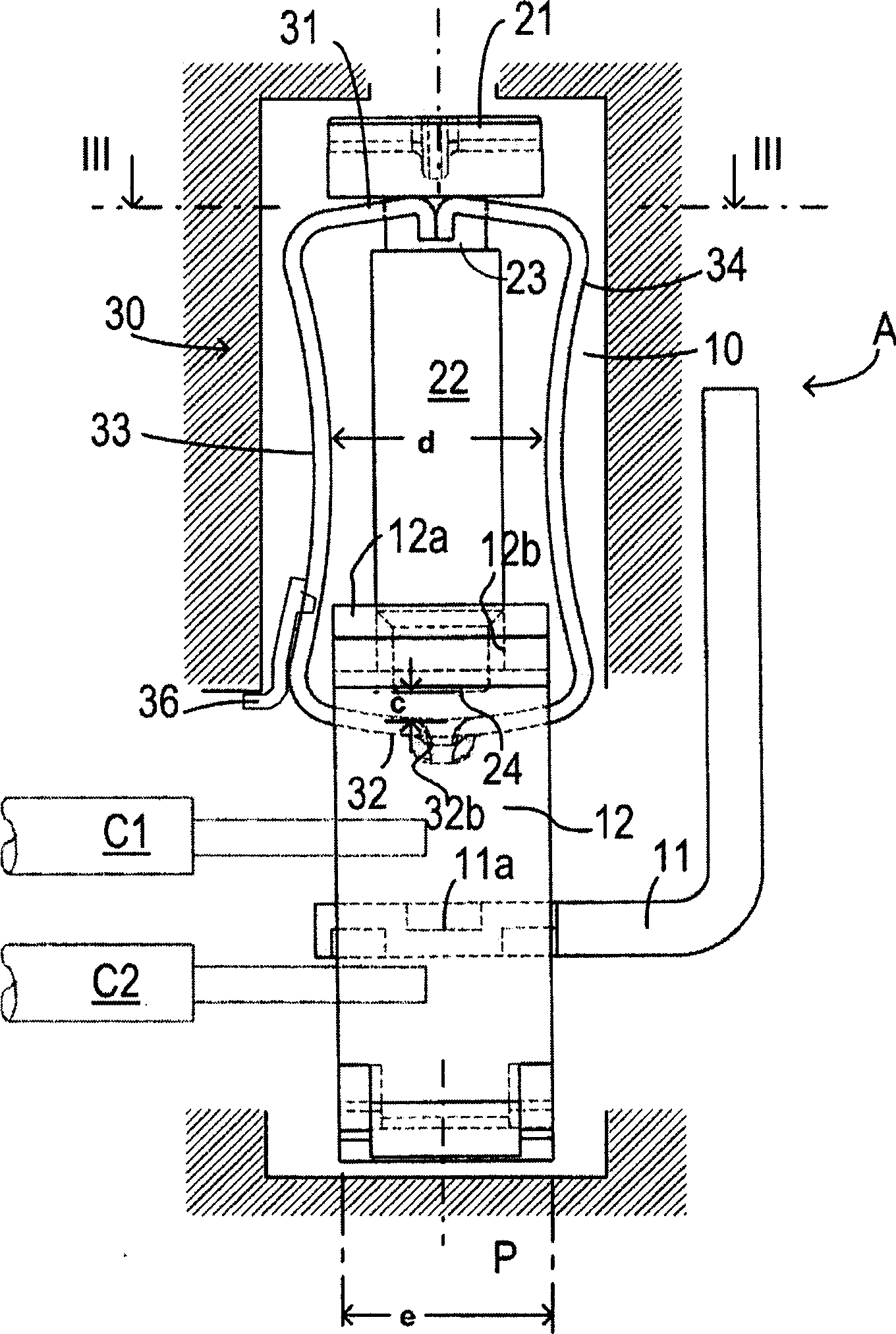

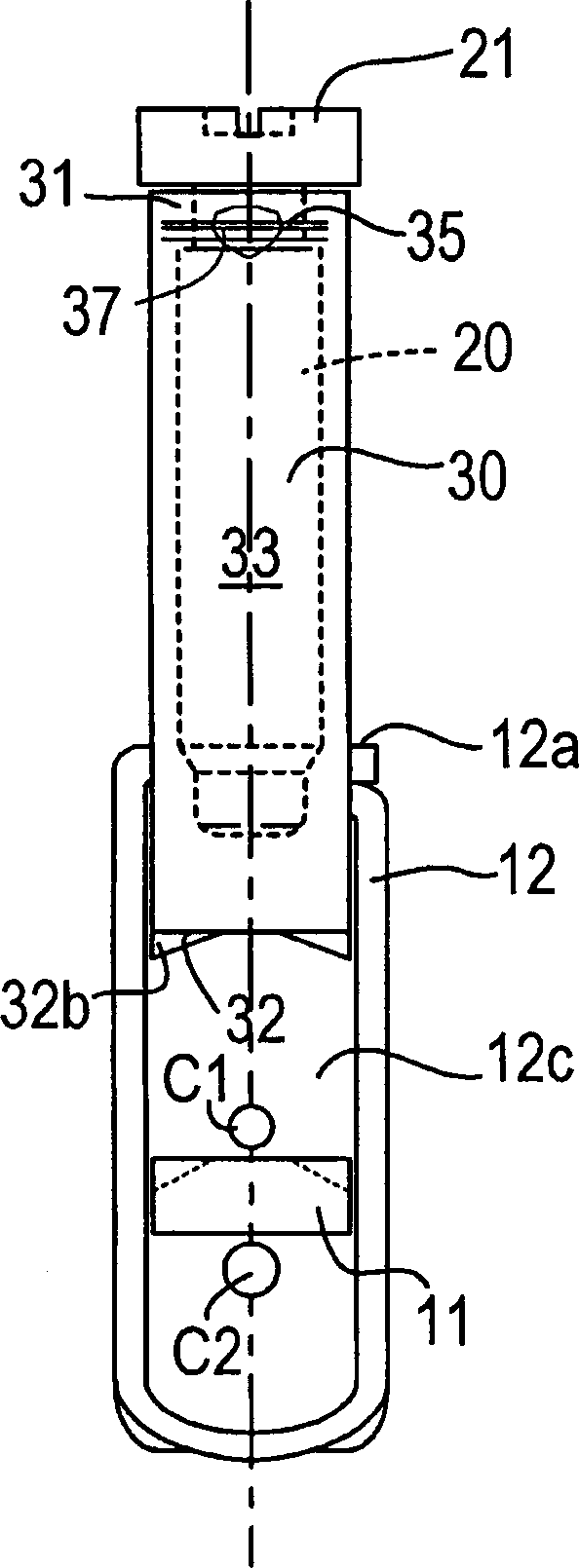

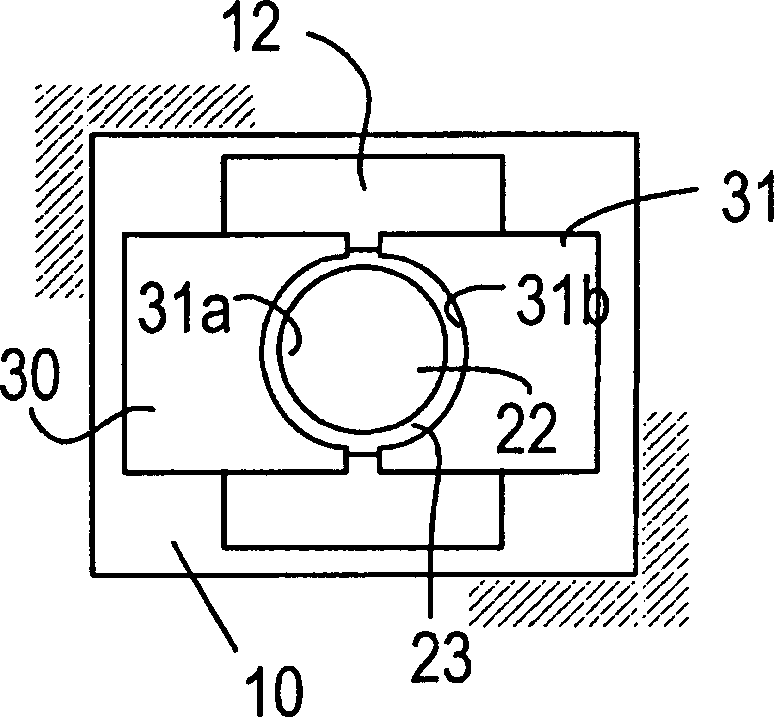

[0014] The screw terminal A shown in the figure is ready to be installed on the electrical equipment. figure 1 Only the following elements of the device are shown in : an insulating housing 10 designed for a terminal block, and a fixed connection branch of a rigid conductor arrangement 11, on which one or several conductors can be screwed and fixed. With this method, figure 1 Two conductors c1 and c2 inserted above and below the branch respectively are shown. The housing 10 is located in the electrical equipment, that is, it is designed in a certain part of the equipment housing or in a lug fixed to the equipment housing.

[0015] The terminal block A consists of a connecting frame 12 of a common type formed by cutting and bending sheet metal to form a rectangular rigid ring. On the short side 12a, the rigid connecting frame 12 has a tapped hole 12b, and the connection branch of the conductor device 11 is inserted into the rectangular elongated hole 12c of the connecting fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com