Integrated LED light-guide display

An integrated display technology, applied in the direction of instruments, electrical components, electric solid devices, etc., can solve the problems of low output light efficiency, low lifespan, and large power consumption of fluorescent lamps for display icons, and achieve clear and vivid display performance and luminous brightness High, the effect of improving light guide efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

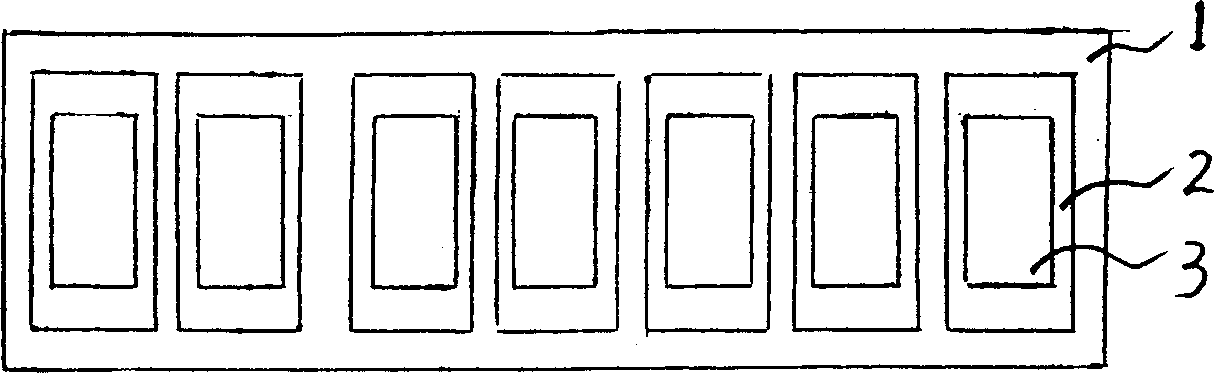

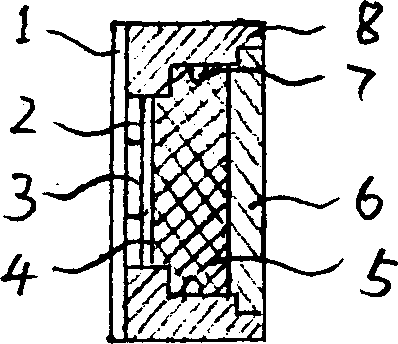

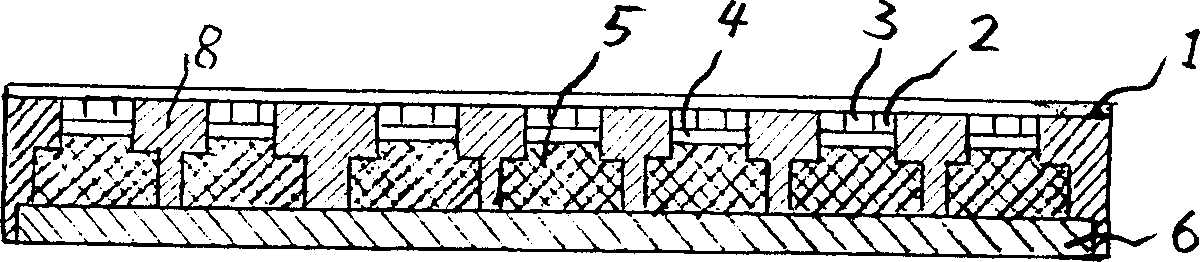

[0023] The given embodiment of the present invention can refer to accompanying drawing:

[0024] First, the light guide plate is prefabricated: the light guide plate 5 can be a single material of organic PmmA or PC, or the substrate is PmmA, the surface is PC or coated with a thin layer of silicone wear-resistant, and the surface of inorganic optical thin glass and organic substrate can also be composited. made. The concave holes 7 on the top of the cylindrical lens are prefabricated on both sides, and the light-emitting diodes are pre-embedded in it, and epoxy-type optical resin glue is injected. If the LED light-emitting tube is arranged on one side, a layer of reflective film can be pasted on the opposite side. On the front of the light guide plate, a rough scattering layer 4 is injected through a film, and the rough scattering layer 4 can form a prismatic concave-convex shape by interlacing dotted lines.

[0025] Secondly, the fixed frame 8 is made into a set of grooves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com