Replaceable machine component of spinning machine with identification marker and system for ensuring quality

A technology for identifying marks and replacing parts, which is applied in the field of replaceable machine parts of a spinning machine with identification marks and systems for quality assurance, and can solve problems such as inability to realize automatic control of spinning cups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

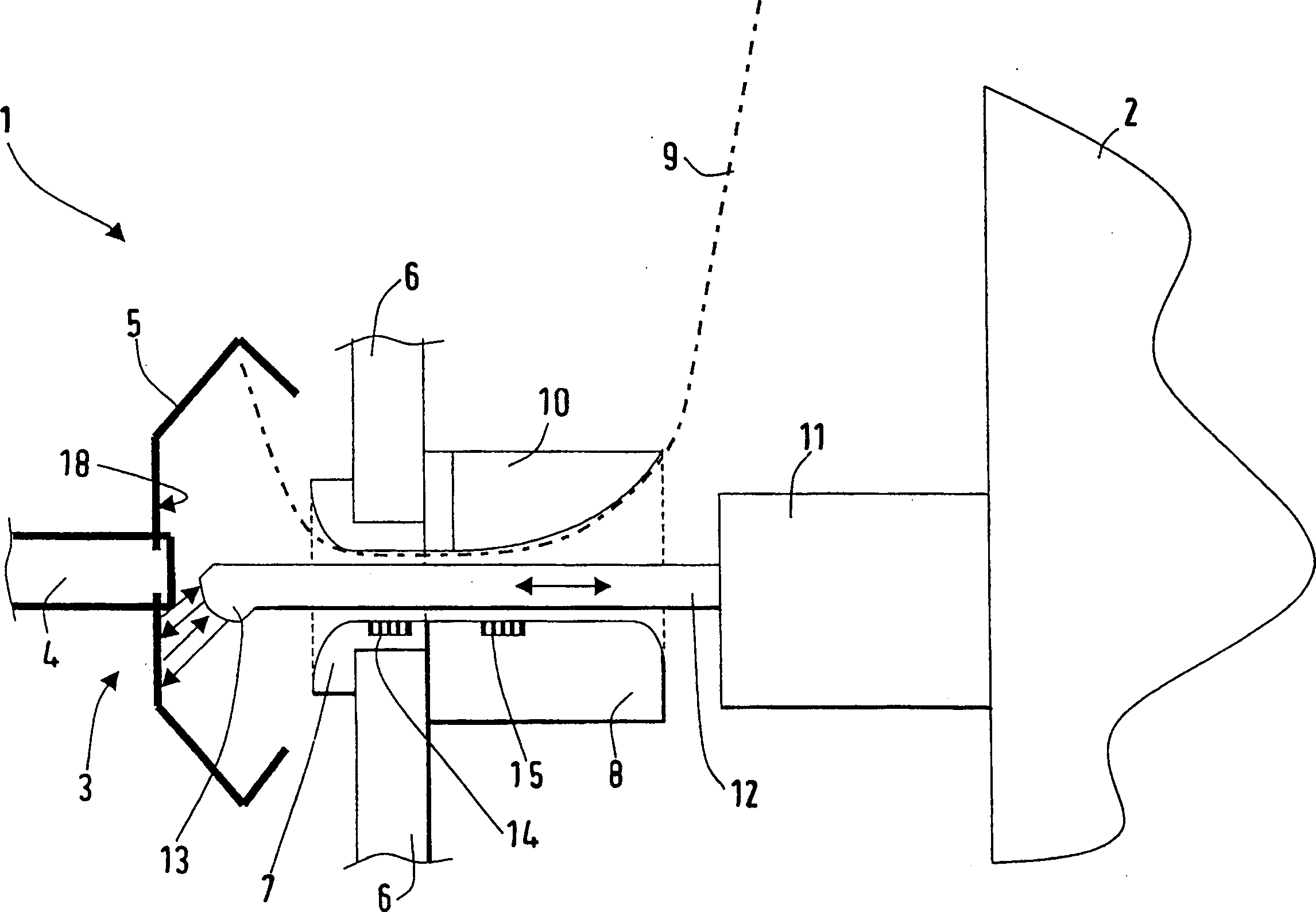

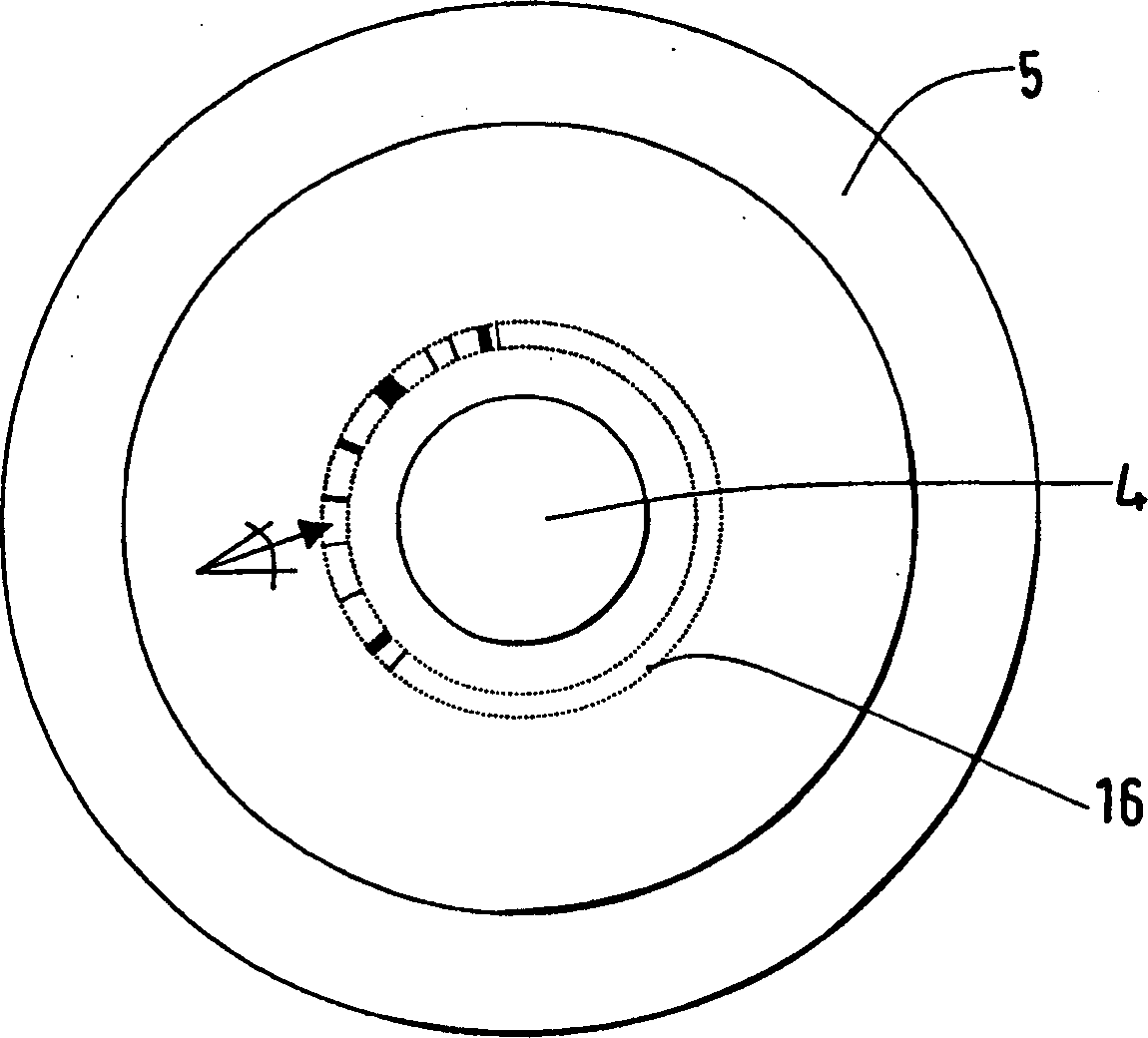

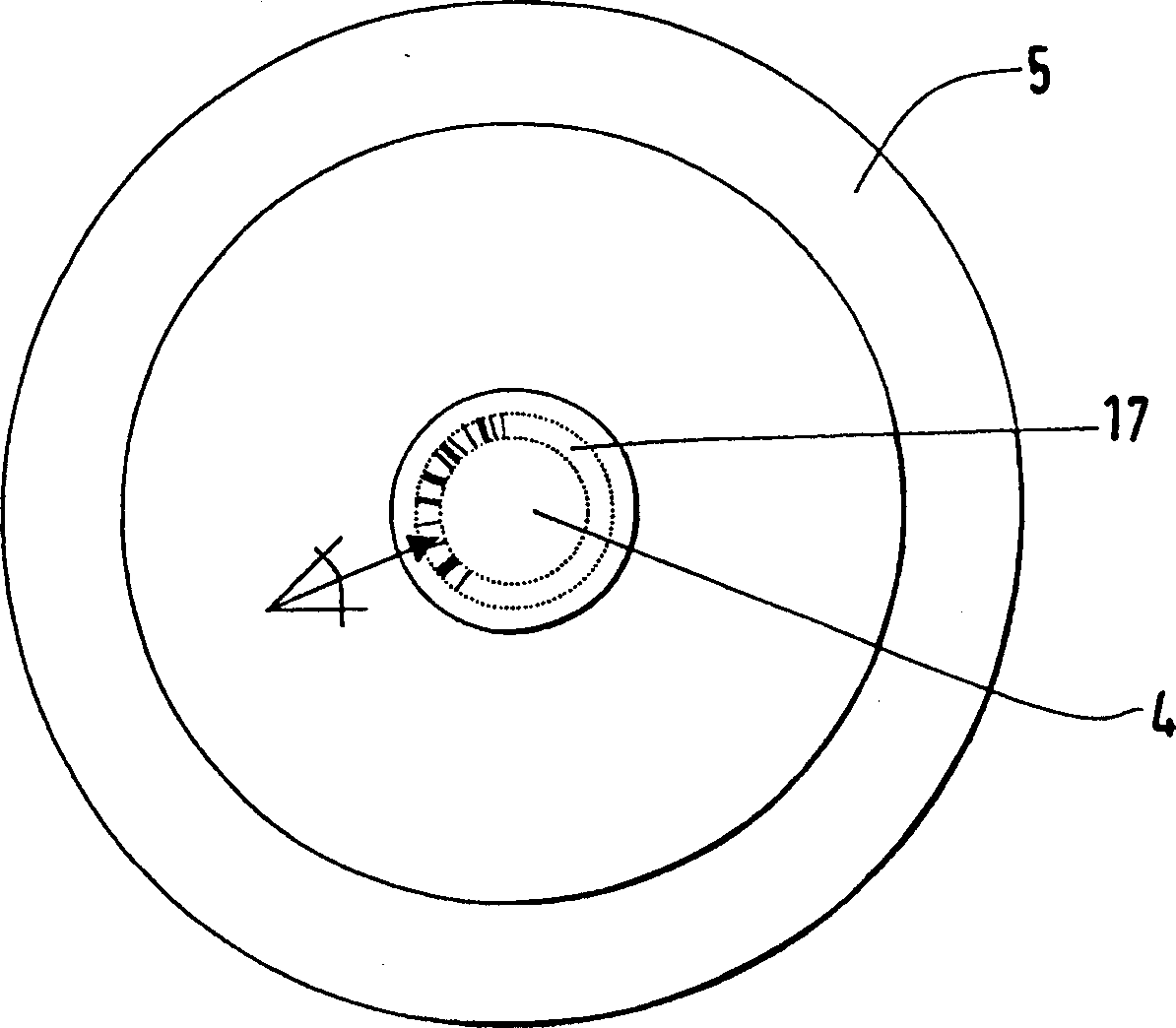

[0037] figure 1 A partial cross-sectional view of a spinning unit 1 of an air (rotor) spinning machine and a partial side view of a remote control mechanism 2 movable relative to the spinning unit 1 are shown. A spinning cup 3 is rotatably mounted and driven in a known manner in the spin box of the spinning device 1 . On the front end of a shaft part 4 of the rotor 3 a rotor disc 5 is fastened. Opposite the open side of the cup tray 5, a yarn withdrawal nozzle 7 is arranged in a cover part 6 of the spin box. On the outer side of the cover 6 a thread pulling tube 8 is connected to the thread pulling nozzle 7 .

[0038] During yarn production, the spun, in figure 1 The yarn 9 represented by the dashed line in the center is pulled out from the groove of the cup tray 5 through the yarn pulling nozzle 7 and the yarn pulling tube 8 . This yarn spinning is realized in a known manner by means of the remote control device 2, and the yarn 9 is wound on a continuously driven bobbin i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com