Producing process for ultraviolet fire-retardant resin spraying material for making immitation leather

A technology of flame retardant resin and spraying materials, which is applied in textiles and papermaking, and can solve the problems of not having both advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

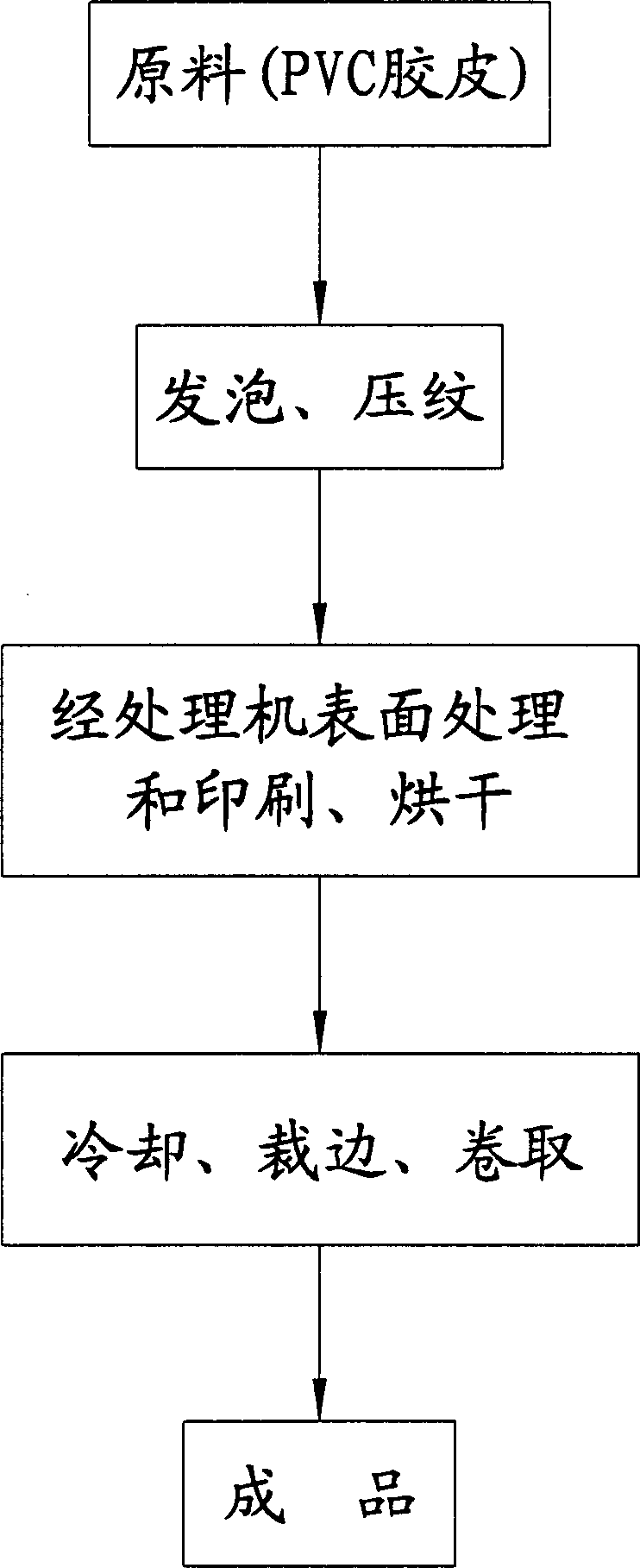

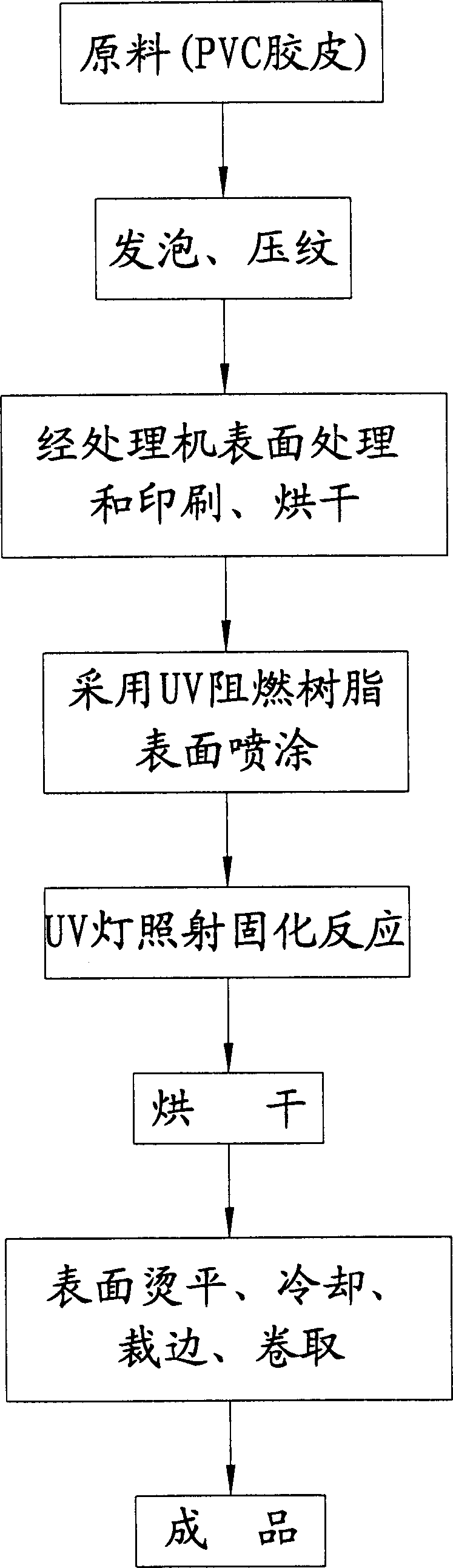

[0013] refer to figure 2 Shown, the production technology of the UV flame retardant resin spraying material tanning disclosed by the present invention is:

[0014] After foaming and embossing the tanning raw materials (such as PVC rubber, etc.);

[0015] Then surface treatment and printing by the processor, and drying;

[0016] Then, use ultraviolet flame retardant resin for surface spraying process, this process can be carried out in the spray booth, spray the liquid ultraviolet flame retardant resin with a viscosity of 50CPS / 25 ℃ on the surface of artificial leather, the amount of spraying can be determined according to the needs, the amount of spraying The size determines the thickness of the protective layer, but the general spraying amount is about 80-100 g / yard. The artificial leather after spraying is too small after 2-3 minutes, the protective layer is too thin, the effect is poor, and the protective layer is too large. Too thick, a waste of cost, leveling, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com