Pollutionless non-metal friction material and its preparing process

A friction material and non-metallic technology, applied in the field of non-polluting non-metallic friction materials and their preparation, can solve problems such as noise pollution, product launch, and scratched counterparts, and achieve the effects of avoiding waste, good product performance, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1, this product is by 25% brucite fiber; 5% metal fiber; 20% plant fiber; 20% phenolic resin; 12% barium sulfate; 5% feldspar; 6% tire powder; 5% fluorite; 1% alumina; 1% zinc stearate.

Embodiment 2

[0017] Embodiment 2, this product is by 45% brucite fiber; 5% metal fiber; 15% modified phenolic resin; 14% barium sulfate; 5% feldspar; 8% tire powder; 6% Fluorite; 1% aluminum oxide; 1% zinc stearate.

Embodiment 3

[0018] Embodiment 3, this product is by 37% brucite fiber; 5% metal fiber; 8% plant fiber; 17% modified phenolic resin; 13% barium sulfate; 6% feldspar; 7% tire powder; 5% fluorite; 1% aluminum oxide; 1% zinc stearate. This embodiment is a preferred example.

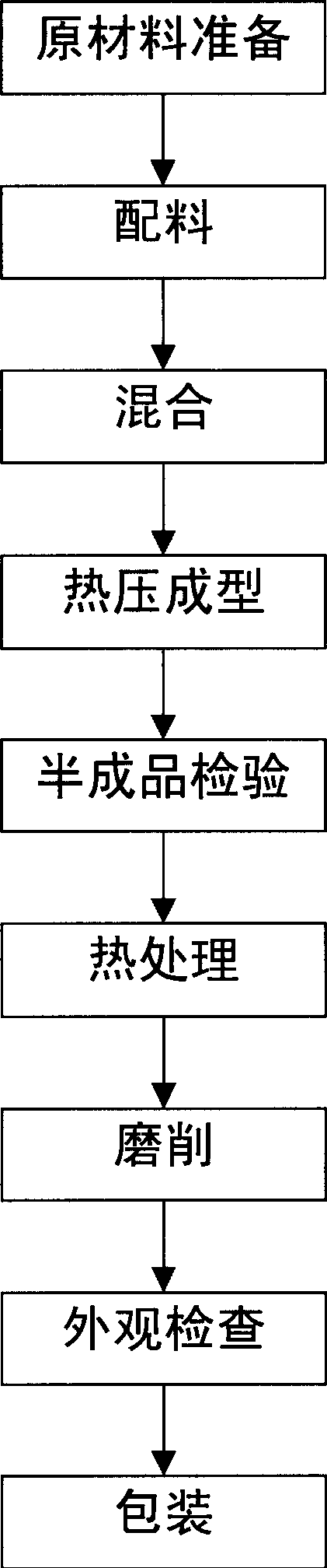

[0019] see figure 1 , The technological process in the prior art is: sequentially including raw material preparation, batching, mixing, thermoforming, semi-finished product inspection, heat treatment, grinding, appearance inspection, and packaging procedures.

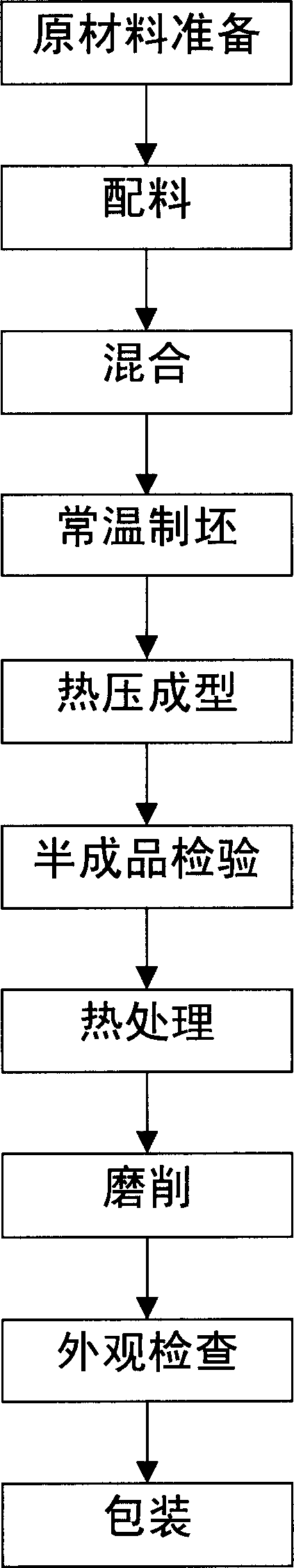

[0020] see figure 2 , the present invention adds a normal-temperature billet-making process between mixing and hot-pressing forming, that is, the mixture is made into a parison at normal temperature, and hot-pressing is performed when the parison is uniform in thickness and meets the requirements.

[0021] During specific implementation, the materials prepared according to the weight percentage are sequentially completed through raw material preparation, batch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com