Waste collecting container for vacuum cleaner

A technology for garbage collection and collection container, which is applied in the directions of vacuum cleaners, suction filters, cleaning equipment, etc., and can solve the problems of complicated maneuverability of garbage collection bags.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

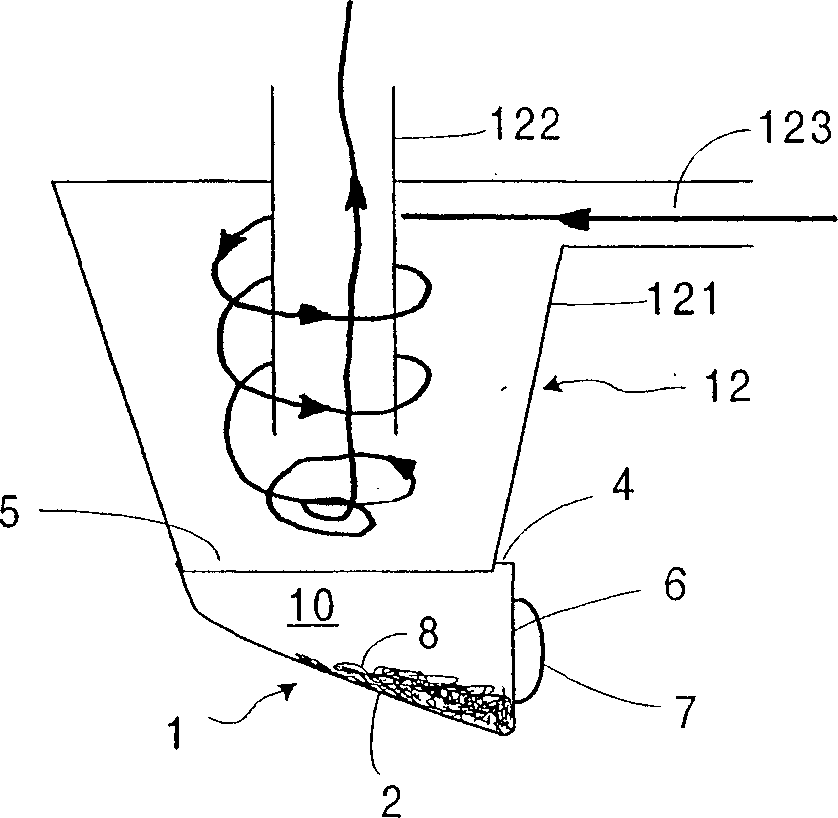

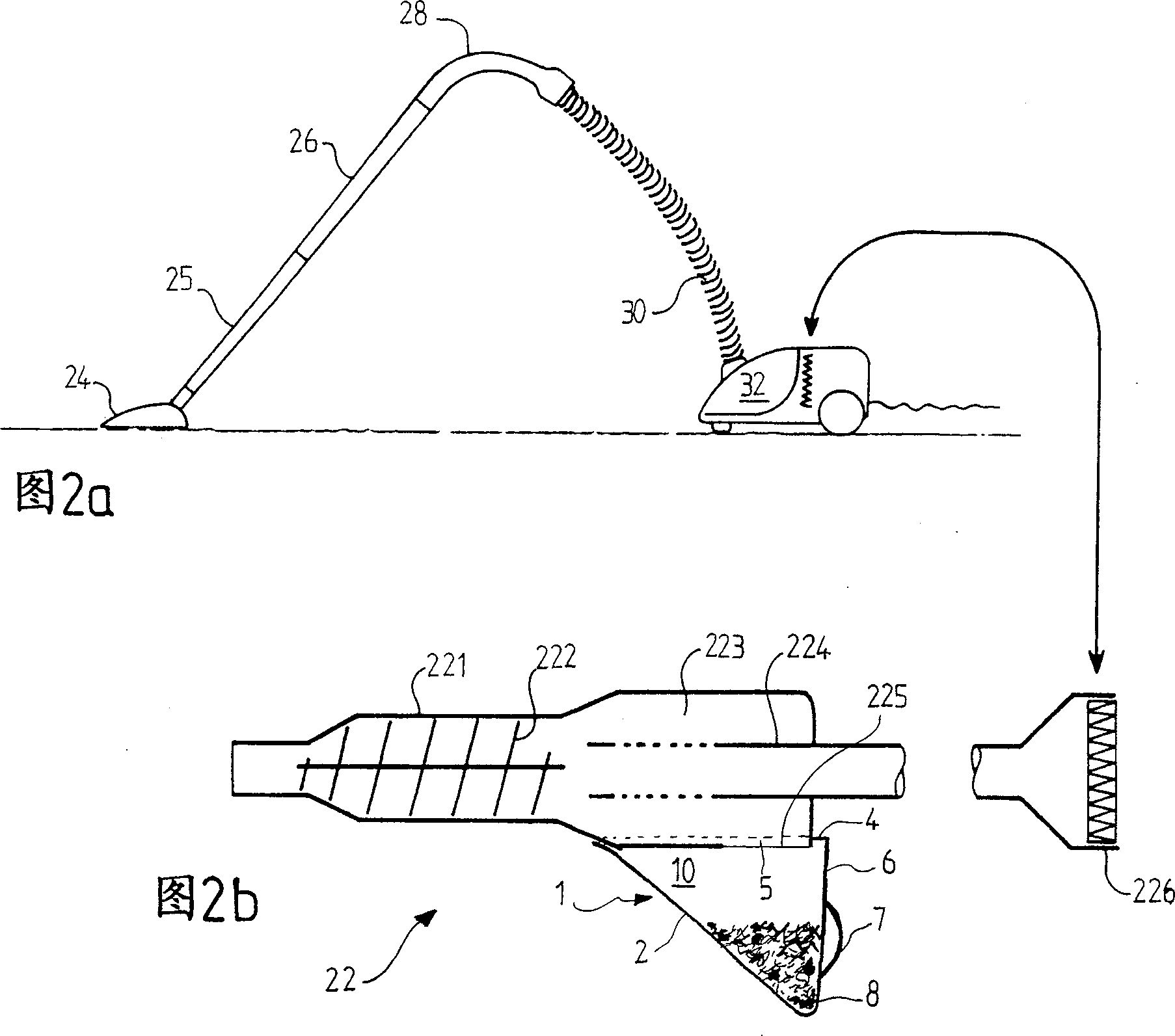

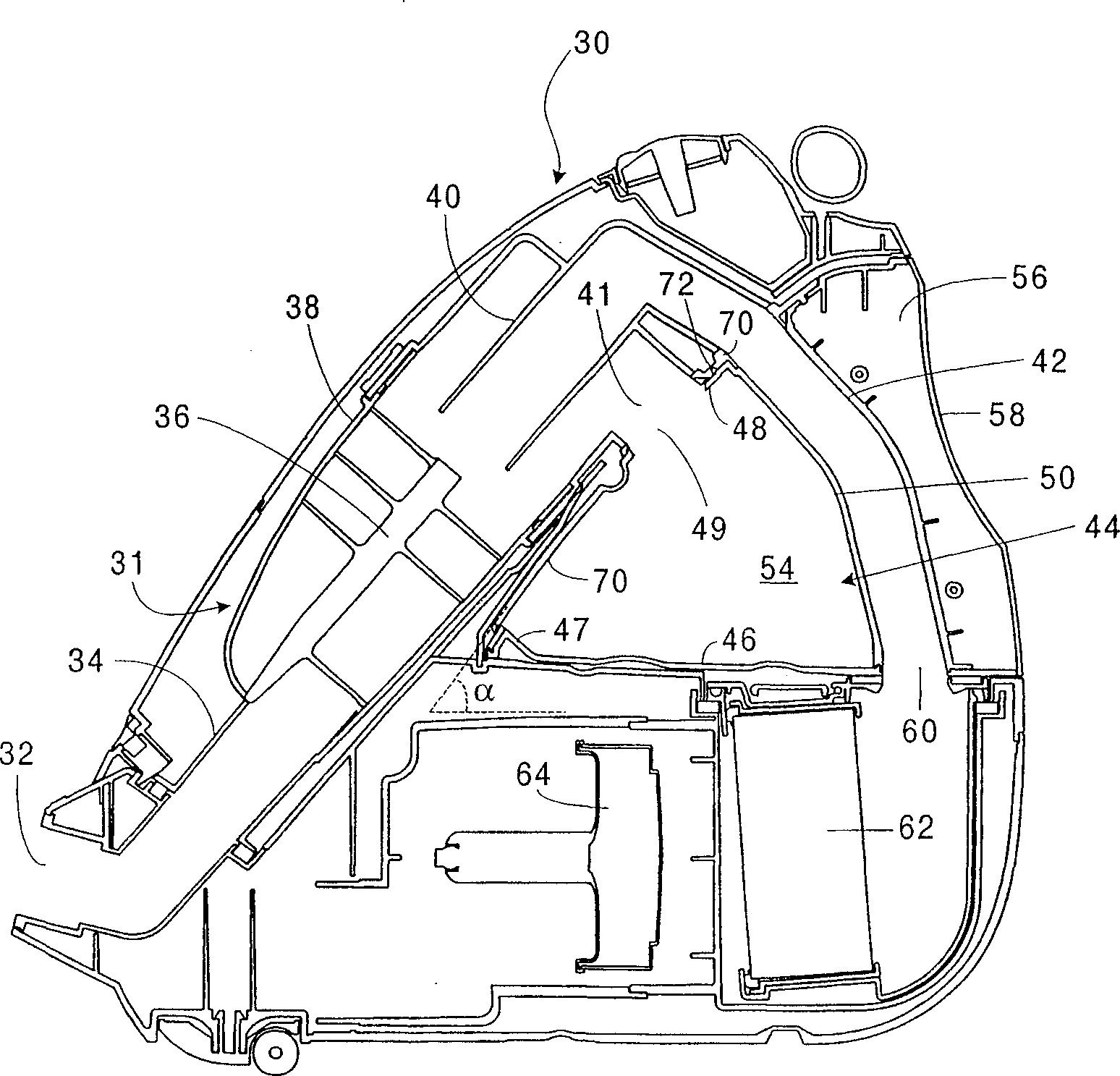

[0046] figure 1 A cyclonic waste separation device 12 is shown, which comprises a frustoconical housing 121 and a pressure delivery pipe 122 . The air drawn in flows through the channel 123 , first spirally descending along the frusto-conical wall 121 , and then ascending along the central axis of the pressure delivery pipe 122 .

[0047] The rubbish 8 separated by the cyclone is collected in a container 1 positioned at the bottom of the device, and the rubbish falls into the collection container under the action of gravity and inertia. The air is discharged free of fine dust particles and is treated further downstream if required.

[0048] According to the invention, the collection container 1 comprises a bottom wall 2 for collecting waste, a connecting wall 4 with a cover 5, a wall 6 with a handle 7, and two side walls, not shown, which define a waste Storage room 10. The openings in the connecting wall 4 allow the waste to enter the collection container from the separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com