Vortex lead jetting type washing water-saving device

A water-saving device and ejector-type technology, applied in water supply devices, chemical instruments and methods, flushing equipment with water tanks, etc., can solve the problems of increasing sewage treatment capacity, large water consumption, troublesome flushing of sanitary ware, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

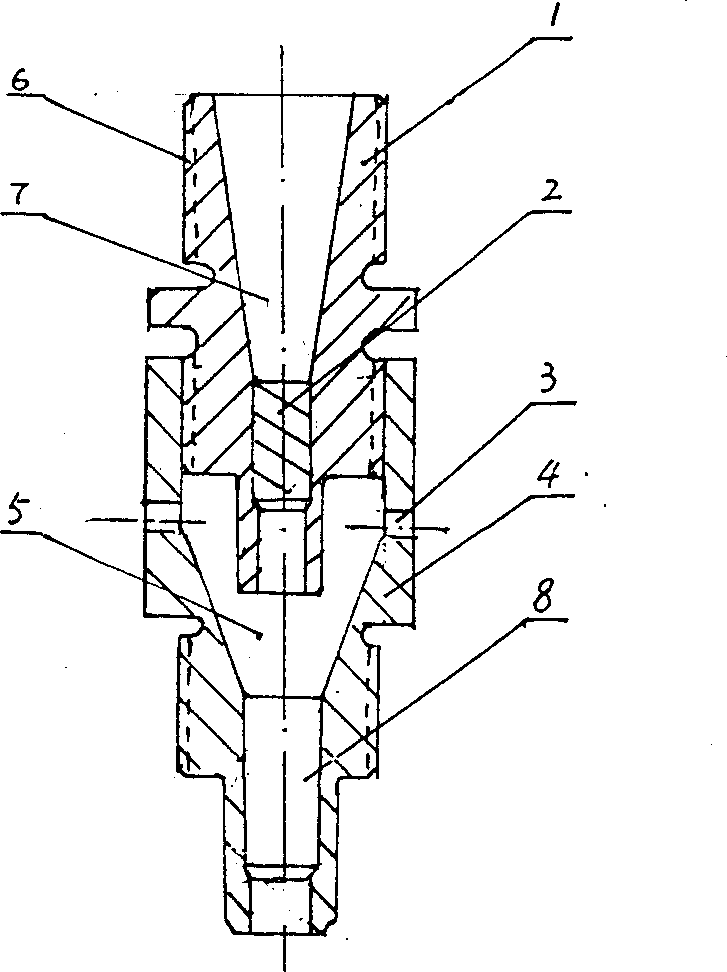

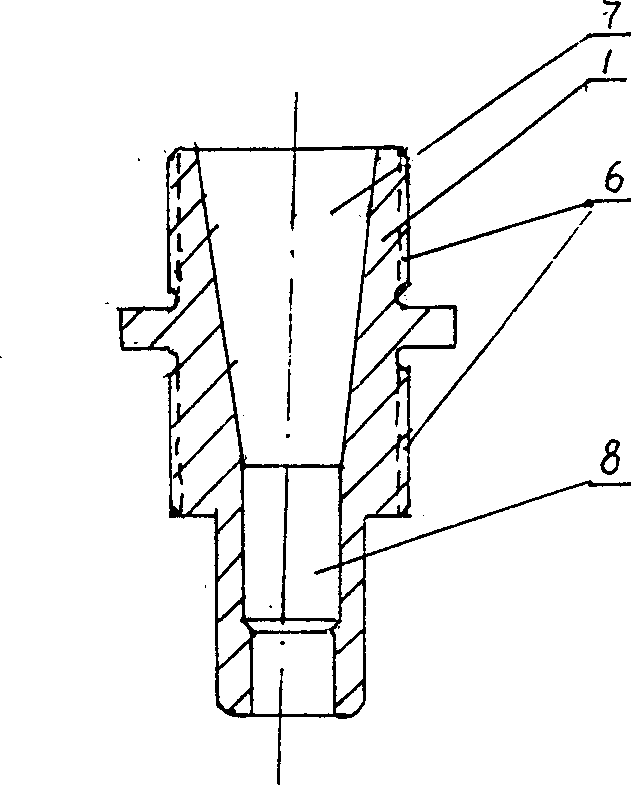

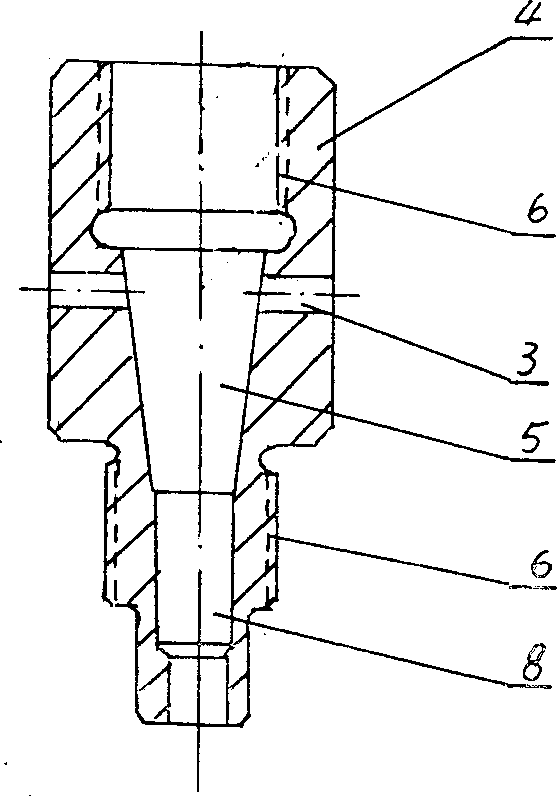

[0008] figure 1 It is also a diagram of a swirl injection type washing water saver for flushing toilets. When the water supply valve connected to the swirler nozzle is opened, the pressure water enters the swirl nozzle 1, accelerates in the converging nozzle 7 and then enters the equal-diameter channel 8, where a high-speed swirling jet is formed through the swirler 2 It flows into the injection gun and sprays to the mixing chamber 5. Due to the high speed and high rotation, the vacuum in the mixing chamber is caused, and the air flows into the mixing chamber through the injection hole 3 and mixes with the rotating water flow to form air-water Two-phase flow, since the mixing chamber itself is also a converging nozzle, this two-phase flow flows through it, is accelerated again, enters the equal-diameter channel at the lower part of the injection gun, and mixes with the air injected into the mixing chamber, The gas-water two-phase flow is further increased in gas content, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com