Appts. for removing fluid component from particulized solid materials

A granular solid and liquid technology, which is applied in the field of devices for removing liquid components and devices for removing moisture, and can solve problems such as unhygienic, failure to achieve fluidization effect, and overheating of food

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

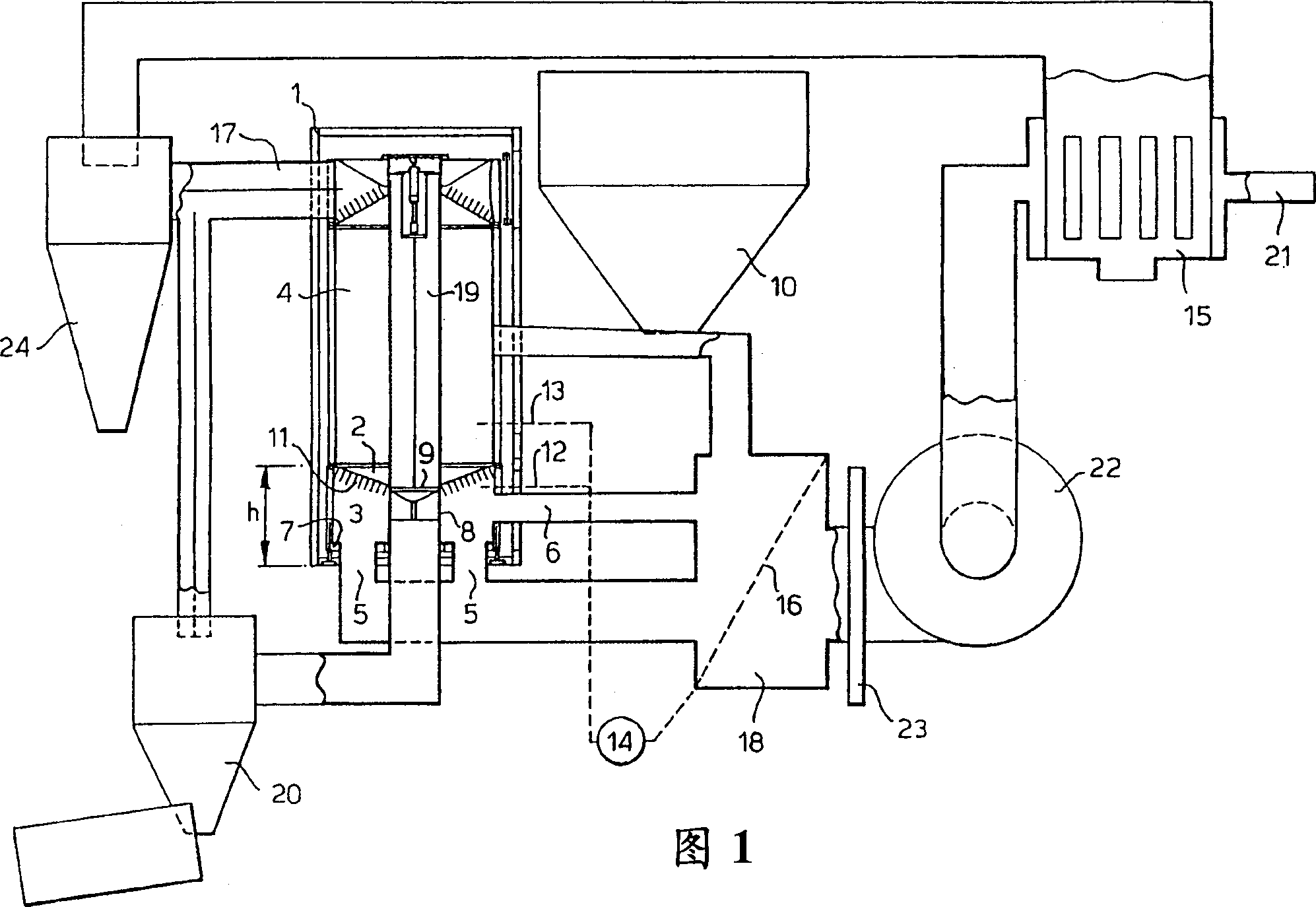

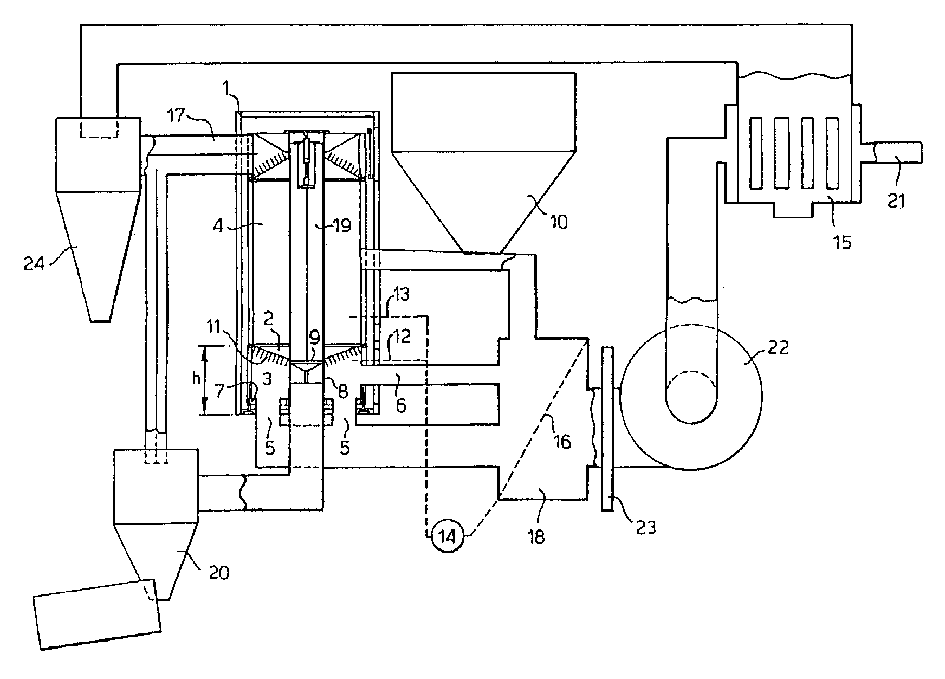

[0035]Materials to be dried, such as rice grains, are transported from the hopper (10) to the reaction chamber (4) of the reactor. The reactor includes a shell (1) with a perforated plate (2), which is pot-shaped And has a perforation (11) with a size of about 2mm, the perforated plate (2) divides the shell (1) into a gas introduction chamber (3) and a reaction / drying chamber (4). The fluidizing gas is introduced through the gas inlet (5) on the bottom (7) of the chamber (3) at a velocity of 15 m / s, and this gas flow brings an axial component to the particles in the chamber (4). Simultaneously another gas is introduced from directly below the plate (2) through the gas inlet (6) at a velocity of 35 m / s. This gas gives a tangential component to the solid particles in the chamber (4). In this way, the solid particulate material forms an annular fluidized bed within the chamber (4). The gas introduced through the openings (5) and (6) is preheated by indirect heat exchange in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com