Open structure digital control system with self-guide secondary development simulation platform

A secondary development, numerical control system technology, applied in the direction of digital control, software simulation/interpretation/simulation, program control devices, etc., can solve the problems of increasing overhead, reducing the processing speed of important control events, and not having the particularity of numerical control machining, achieving Guaranteed stable and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Below in conjunction with accompanying drawing, the implementation of the present invention is described as follows:

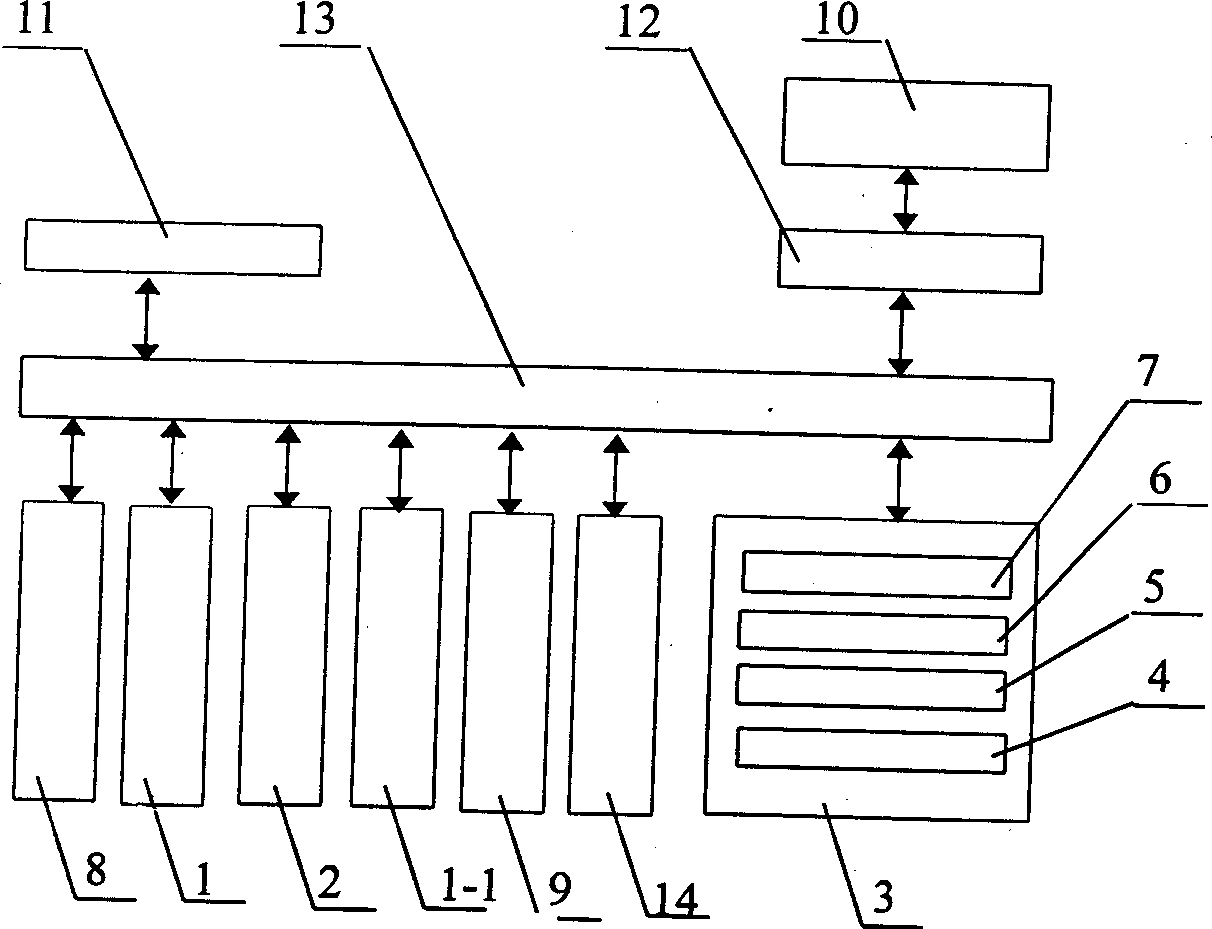

[0057] exist figure 1 Among them, central microprocessor 1, high-speed DSP processing chip 1-1, general control and interaction management chip 2, storage chip 3, current clock circuit 14, general control and user interaction interface 11, data resource management chip 8, secondary development The simulation control chip 9 and the secondary development simulation interface 12 are connected to the system bus 13 respectively. The secondary open development platform 10 of the PC-based numerical control system is connected with the secondary development simulation interface 12 by a bus. The storage chip 3 is composed of a system work ROM storage chip 4, a data storage FIASH-ROM storage chip 5, a simulation development RAM storage chip 6 and a secondary development FIASH-ROM storage chip.

[0058] in,

[0059] 1. The central microprocessor 1 is used for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com