Elastic boring bar

An elastic and boring bar technology, which is applied in the direction of boring bar, boring machine/drilling machine parts, drilling/drilling equipment, etc., can solve the problem that the boring bar cannot automatically adjust the tool, and achieve the effect of automatic tool adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

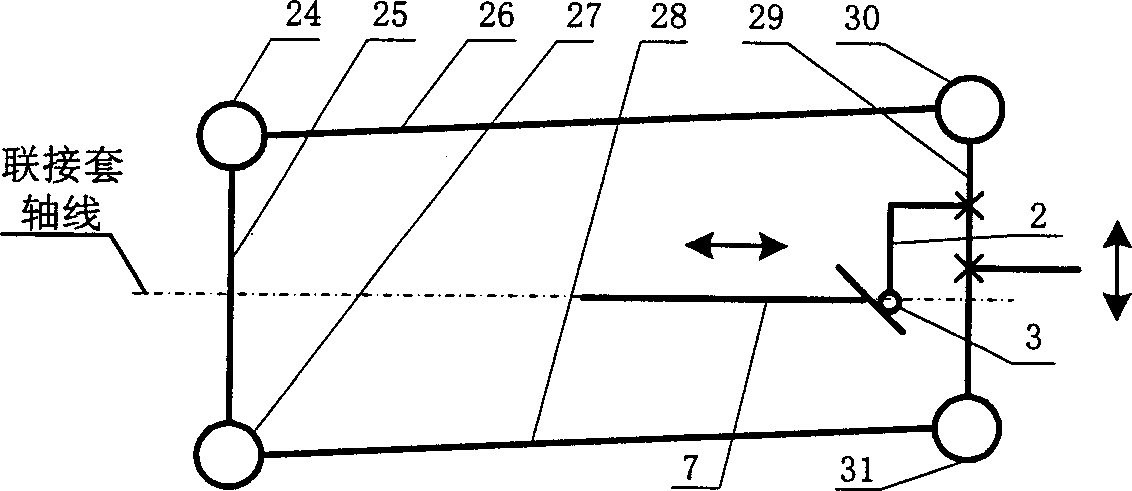

[0013] exist figure 1 Among them, the first connecting rod 25 is a simplified body of the coupling sleeve and the rear section of the elastic deformation body, the second and fourth connecting rods 26, 28 are respectively simplified bodies of the upper and lower parts of the middle section of the elastic deformation body, and the third connecting rod 29 is an elastic body. The simplified body of the front section of the deformable body, the first to the fourth hinges 24, 27, 30, 31 are respectively simplified bodies of four thin walls parallel to each other of the elastic deformable body, and they constitute a parallelogram four-bar linkage mechanism.

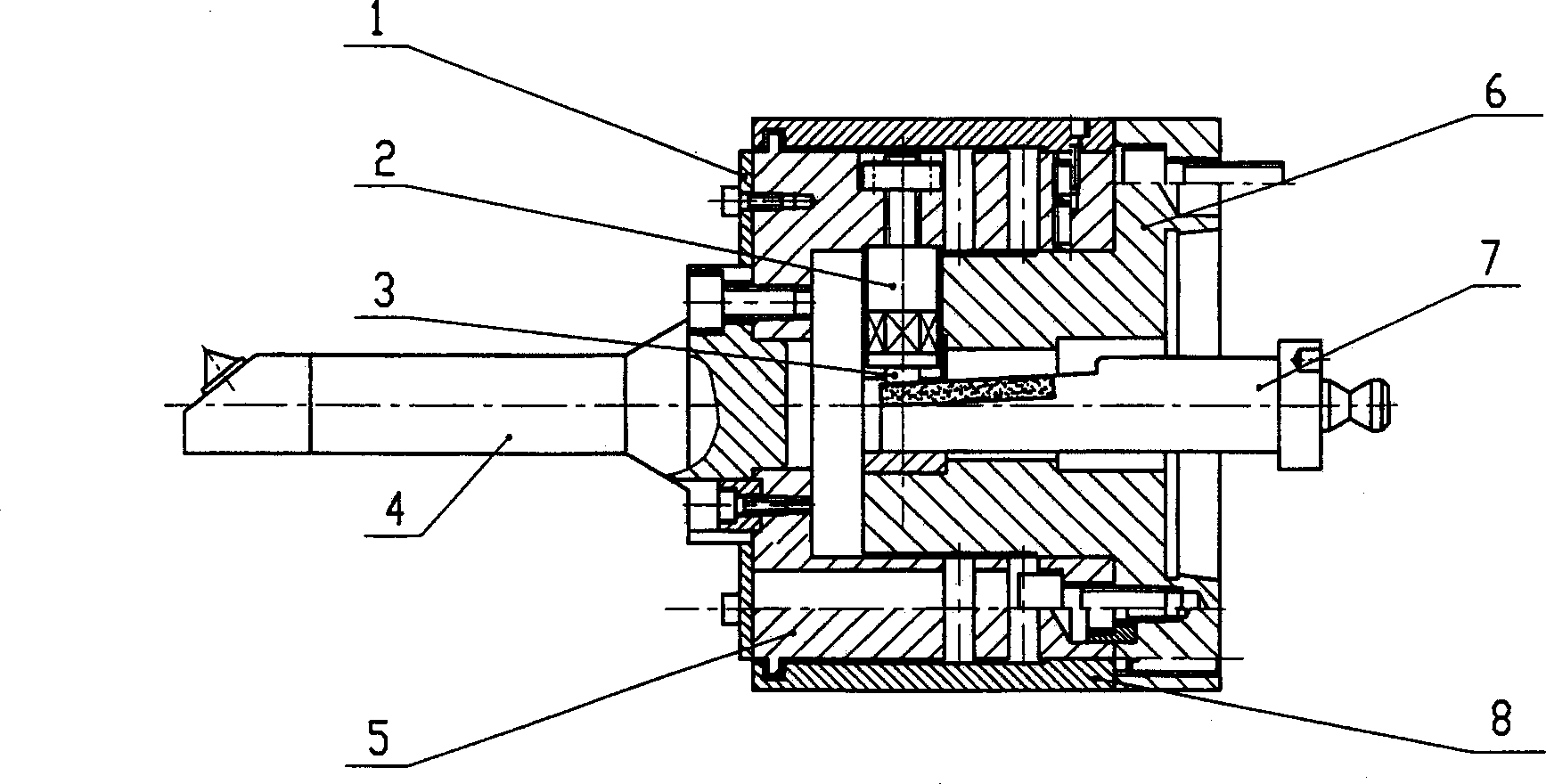

[0014] Such as figure 2 Shown, the present invention can be divided into rod body and the cutter bar two parts that are connected with it that boring tool is housed, and rod body is made of elastic deformation body 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com