Method of utilizing plant straw to green rocky side slope

A stone slope and straw technology, applied in botany equipment and methods, plant protection covers, excavation, etc., can solve problems such as abnormal growth, plant diseases and insect pests, and mold growth on the surface of the slope, so as to reduce disease The effects of seed damage occurrence, reasonable physical structure and reduced construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

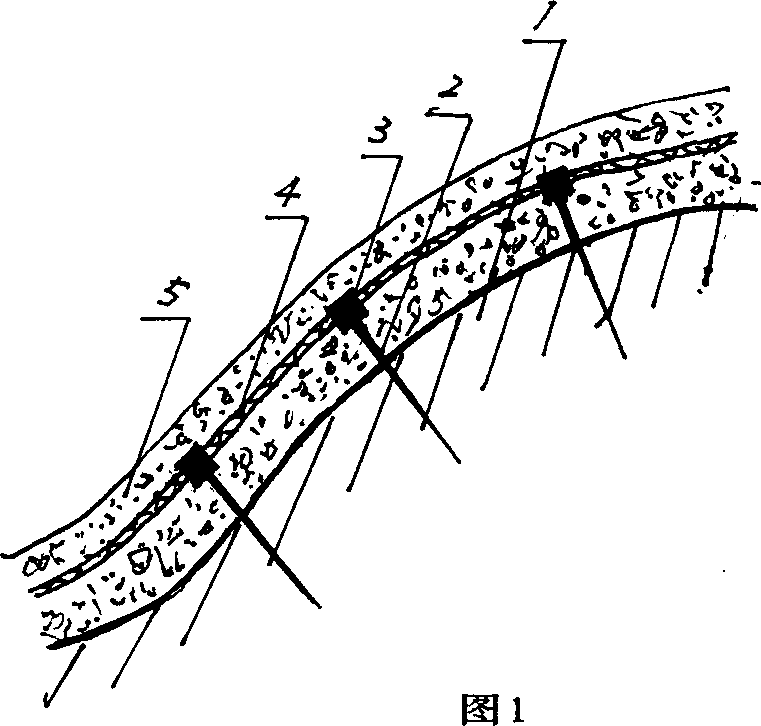

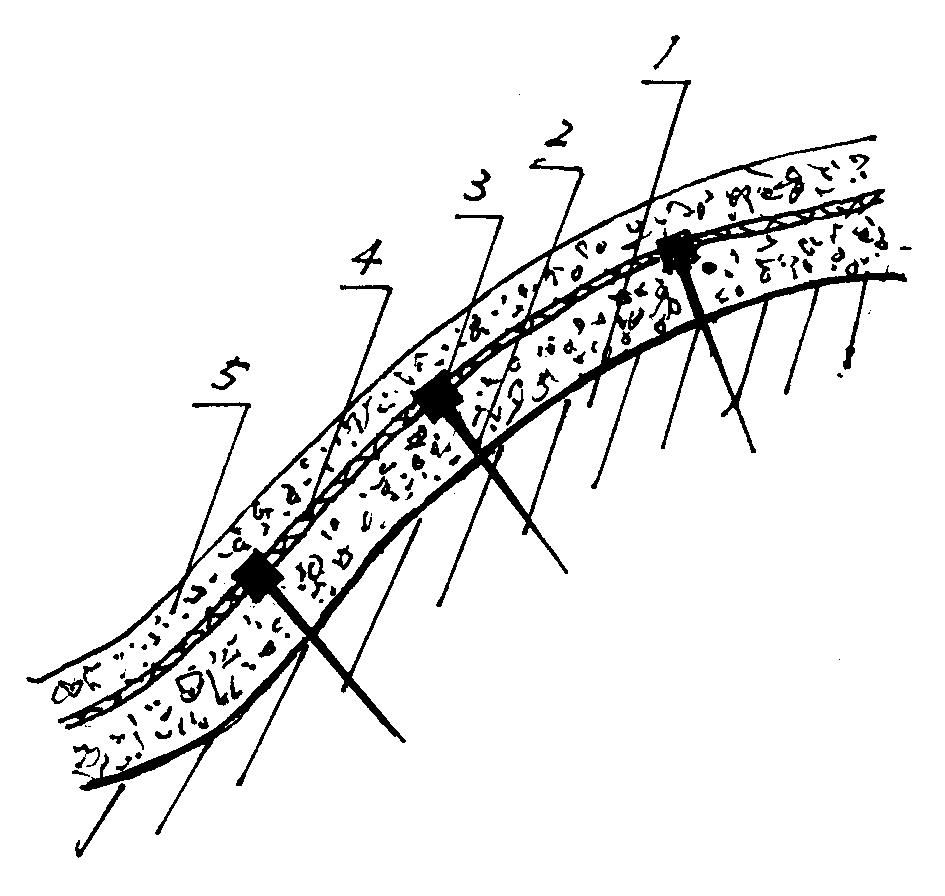

[0010] Take 21.8kg of rape stalks crushed to a length less than 2cm, 0.41kg of urea, 0.42kg of potassium chloride, 0.31kg of superphosphate, 77kg of planting loam, 0.02kg of chlorinated nitrobenzene, and 0.04kg of perennial ryegrass seeds, and mix them with a mixer Uniform; install anchor rods on the stone slope with a slope of 1:0.75, and fix 14# galvanized welded steel wire mesh (mesh hole 50×50mm) on the slope with a supporting plate, and the distance between the wire mesh and the slope is 4cm; Use the improved concrete sprayer to spray the mixture onto the slope, add 111Kg of water during the spraying process, and the spraying thickness is 10cm to form the slope covering layer as shown in Figure 1. Among them, 1 is the stone slope, 2 is the anchor rod, 3 is the support plate, 4 is the grid, and 5 is the slope covering layer.

[0011] Seven days after the construction, Bermudagrass began to germinate, and the vegetation coverage rate reached over 95% one month later. After ...

Embodiment 2

[0013] Take 28.4kg of straw straw, 0.51kg of ammonium nitrate, 0.51kg of potassium sulfate, 0.50kg of superphosphate, 70kg of planting loam, 0.04kg of carbendazim, and 0.04kg of bermudagrass seeds crushed to a length of less than 3cm, and mix them evenly with a mixer ;Anchor rods are installed on the stone slope with a slope of 1:0.5, and 14# galvanized welded steel wire mesh (mesh hole 50×50mm) is fixed on the slope surface with a supporting plate, and the distance between the wire mesh and the slope surface is 6cm; The above-mentioned mixture is sprayed onto the slope with an improved concrete sprayer, and 91Kg of water is added during the spraying process, and the spraying thickness is 14cm to form a slope protection covering layer as shown in Figure 1.

[0014] Four days after construction, ryegrass began to germinate, and one month later, the vegetation coverage rate reached over 95%. After two to three months of construction, the vegetation grew well, and the three-phase ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com