Carding machine

A technology of carding machine and dirt, applied in the field of carding machine, can solve the problem of difficult to achieve siphon and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

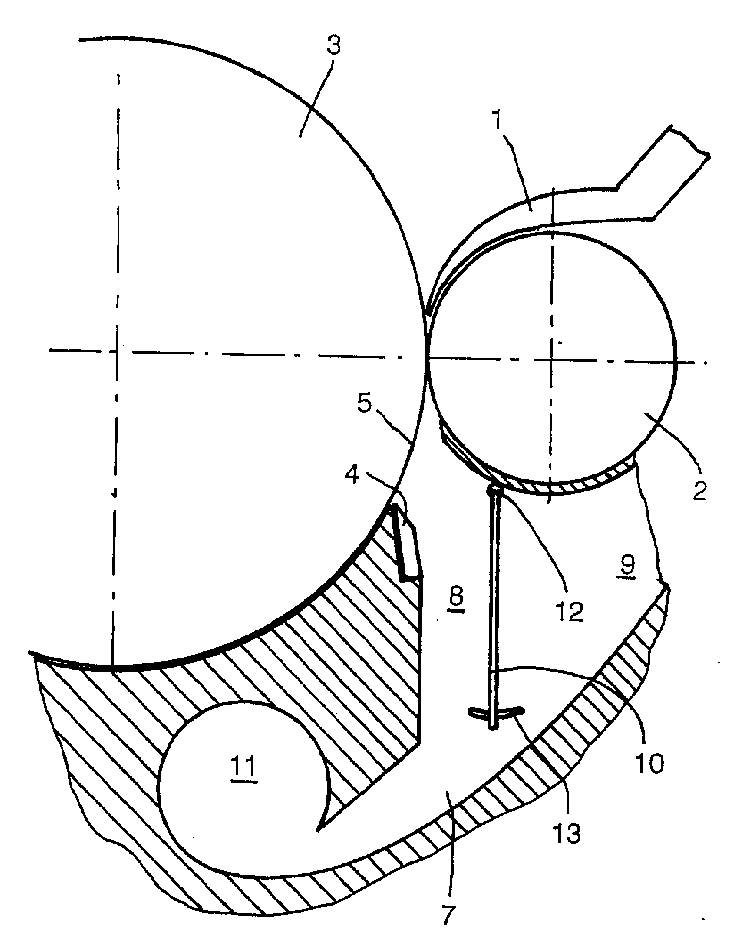

[0022] In the suction zone where the fibers are fed into the card, not shown, a feed disc 1 cooperating with a feed roll 2 is provided. Between the feeding tray 1 and the feeding roller 2, the fiber plush bundle is sent to the opening roller 3 in the form of fleece, and the opening roller is also called licker-in roller or licker-in roller. The opening roller 3 separates the fibers introduced into the individual fiber strands. The impurities contained in the pile fabric are fed to the feed roller 2 and the opening roller 3 together with the fibers. Due to the centrifugal force acting on the impurities, these impurities are centrifugally removed from the opening roller 3 on the opening roller 3, or at least, the lighter or more inert good fibers are carried further by the opening roller 3 due to their mass. rise. It is also beneficial to separate the dirt particles from the good fibers by means of a separating knife 4 which defines a dirt separating hole 5 in the shell 6 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com